High-value treatment method of biogas slurry and biogas residues

A treatment method and high-value technology, applied in the direction of liquid/slurry treatment, bio-organic part treatment, application, etc., can solve the problems of difficult digestion of biogas slurry and difficulty in rational utilization of biogas slurry and residue, and achieve cost saving and composting The effect of high-quality products and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

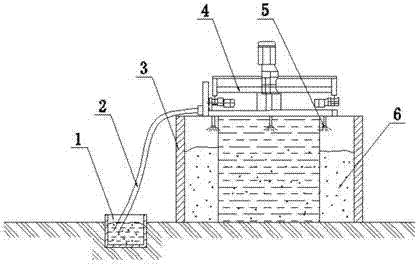

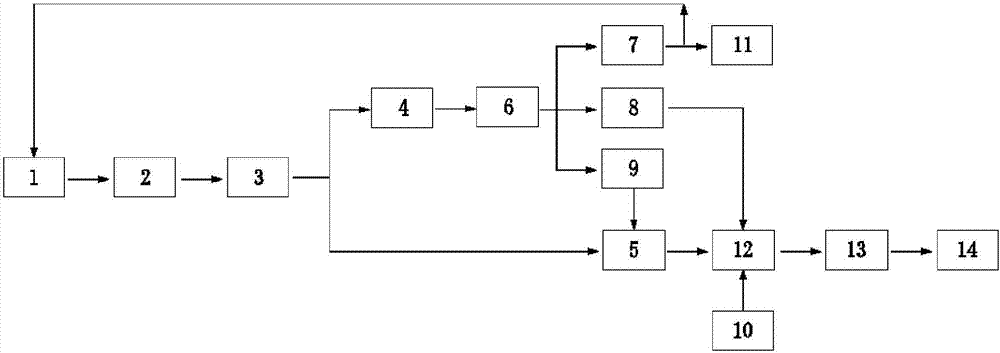

[0024] Such as figure 1 As shown, 1 is anaerobic digester, 2 is biogas slurry and residue mixture, 3 is solid-liquid separation equipment, 4 is biogas slurry, 5 is biogas residue, 6 is sedimentation tank, 7 is supernatant, 8 is suspension Biogas slurry, 9 is sludge, 10 is straw and fungus residue, 11 is flushing water, 12 is aerobic composting workshop, 13 is fertilizer processing equipment, and 14 is organic fertilizer.

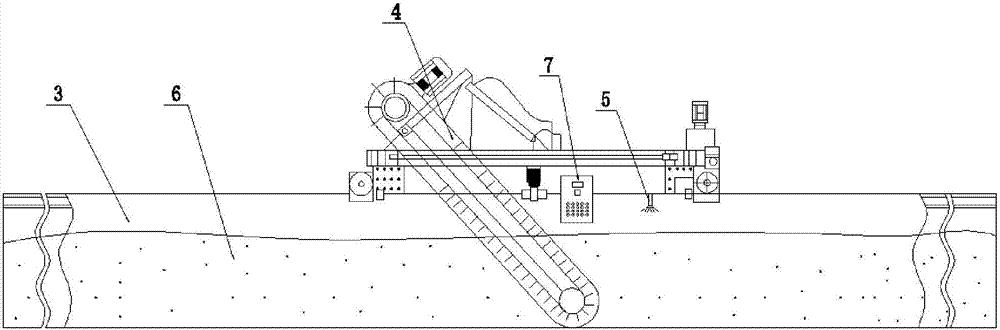

[0025] Such as figure 2 , image 3 As shown, A1 is the biogas slurry storage ditch, A2 is the biogas slurry upper water pipe, A3 is the compost tank, A4 is the turning equipment, A5 is the sprinkler head, A6 is the material pile, and A7 is the controller.

[0026] Attached below figure 1 , figure 2 and image 3 Embodiments of the present invention are described:

[0027] Such as figure 1 , figure 2 , image 3 As shown, the biogas slurry and residue mixture 2 discharged from the anaerobic digester 1 first passes through the solid-liquid separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com