Material conveying device for concrete mixing plant

A mixing station and concrete technology, which is applied in the field of conveying devices for concrete mixing stations, can solve the problems of uncontrollable lifting angle of conveying materials and inability to adjust the height of conveying pipes, etc., so as to improve the scope of use and practicability, facilitate cleaning and maintenance, The effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

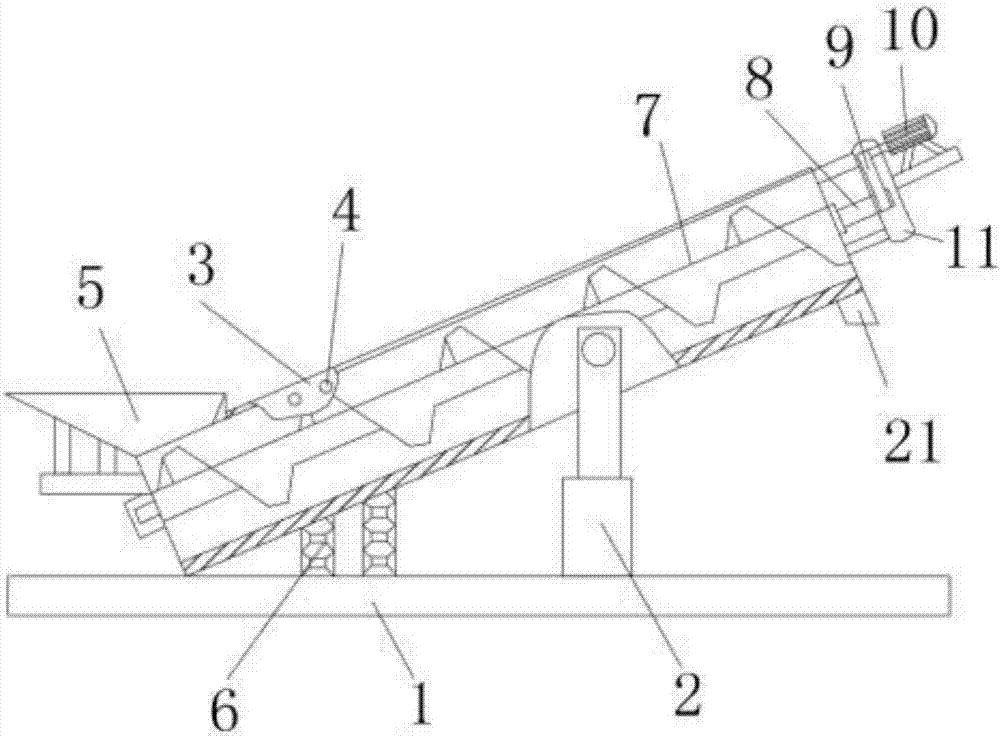

[0024] Embodiment one, with reference to Figure 1-3 , a conveying device for a concrete mixing station, comprising a base plate 1 and a feed pipe 3, a hydraulic telescopic rod 2 is connected at the middle position between the base plate 1 and the feed pipe 3, and the hydraulic telescopic rod 2 and the base plate 1 are perpendicular to each other, and the base plate 1 and the feeding pipe 3 are located on one side of the hydraulic telescopic rod 2 and are connected with an elastic rod 6. The top shell at one end of the feeding pipe 1 is welded with a feeding port 5, and the bottom shell at the other end of the feeding pipe 1 is provided with a Outlet 21, an overflow hole 4 is provided on the surface shell of the feeding pipe 1, a screw feeding shaft 7 is arranged at the inner center of the feeding pipe 1, and a connecting shaft 8 is fixed at one end of the screw feeding shaft 7, and The connecting shaft 8 is connected with the transmission motor 10 through the belt 9, the belt...

Embodiment 2

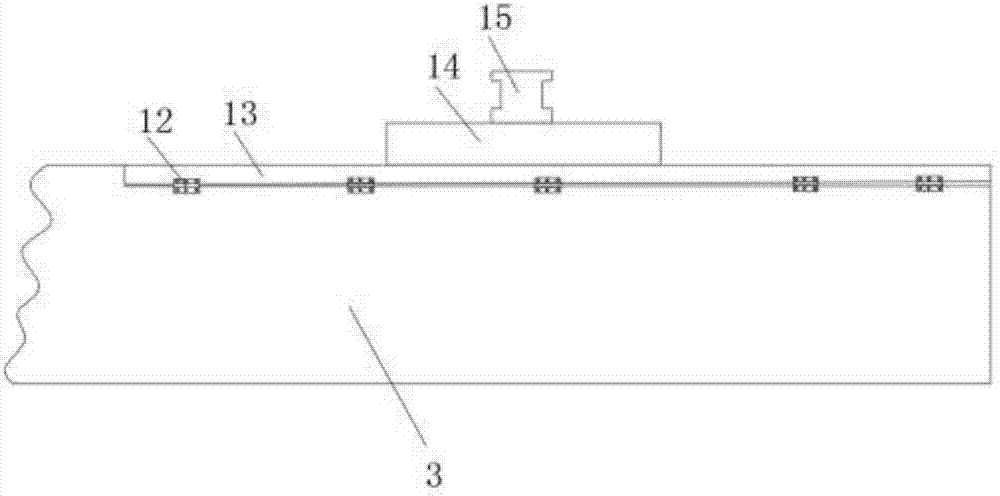

[0025] Embodiment two, refer to figure 1 with figure 2 The feeding pipe 3 is a rectangular structure, and the opening at the top of the feeding pipe 3 is connected with a sealing cover 13 by a hinge 12, and a gasket is provided at the junction of the sealing cover 13 and the feeding pipe 3, and the sealing cover 13 is arranged so that the feeding The feed pipe 3 is not a fully enclosed structure, which is convenient for cleaning and maintenance of the internal structure of the feed pipe 3, and also facilitates the dredging when the feed pipe 3 is blocked during improper operation.

Embodiment 3

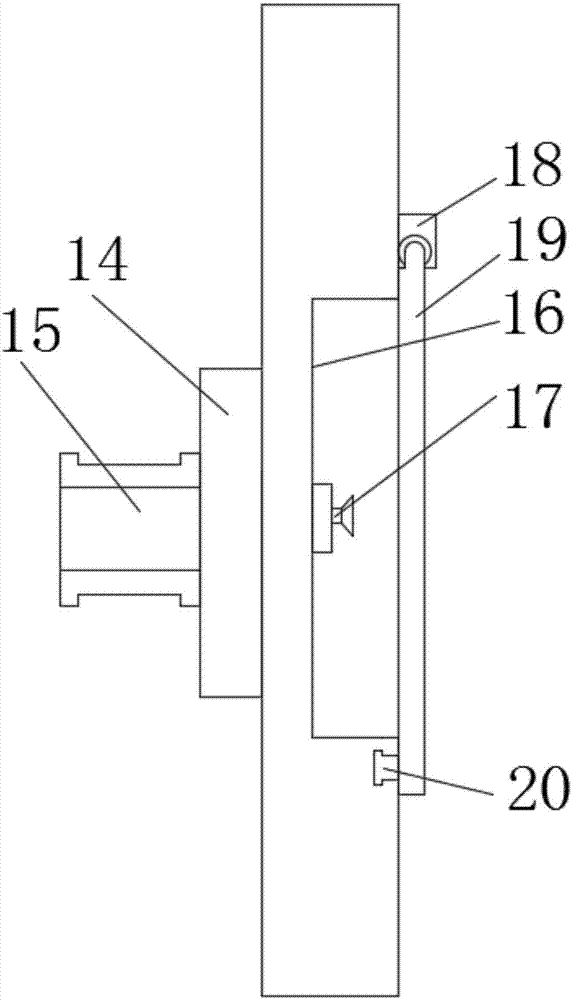

[0026] Embodiment three, refer to Figure 1-3 , a booster pump 14 is provided at the center of the top shell of the seal cover 13, and a water inlet pipe 15 is connected to the booster pump 14, a groove 16 is opened at the center of the back of the seal cover 13, and the inner bottom plate of the groove 16, etc. A spray head 17 is arranged at the distance, and a seal plate 19 is provided at the opening of the groove 16, and one end of the seal plate 19 is rotatably connected with the seal cover 13 through a rotating shaft 18, and the other end of the seal plate 19 is provided with an elastic buckle 20. The setting can realize the self-cleaning of the feeding pipe 3, which makes the feeding device more convenient to use. The setting of the booster pump 14 increases the water pressure, improves the pressure of the water sprayed by the nozzle 17, improves the quality of its flushing, and seals The arrangement of the plate 19 can seal the groove 16. When the nozzle 17 is not used,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com