Full-automatic intelligent cutting all-in-one machine

An intelligent cutting and all-in-one machine technology, applied in the field of machinery, can solve the problems of high labor intensity, damage to the appearance, food contamination, etc., achieve the effect of neat and sharp cutting surface, reduce cutting difficulty, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

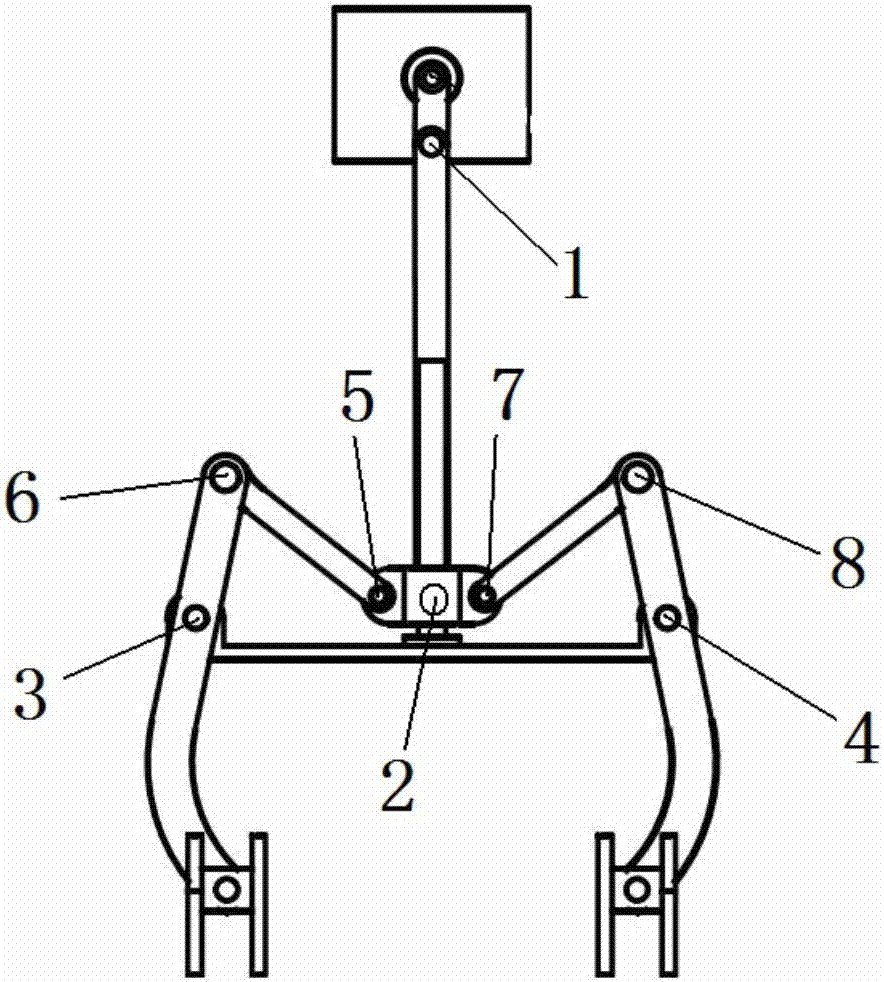

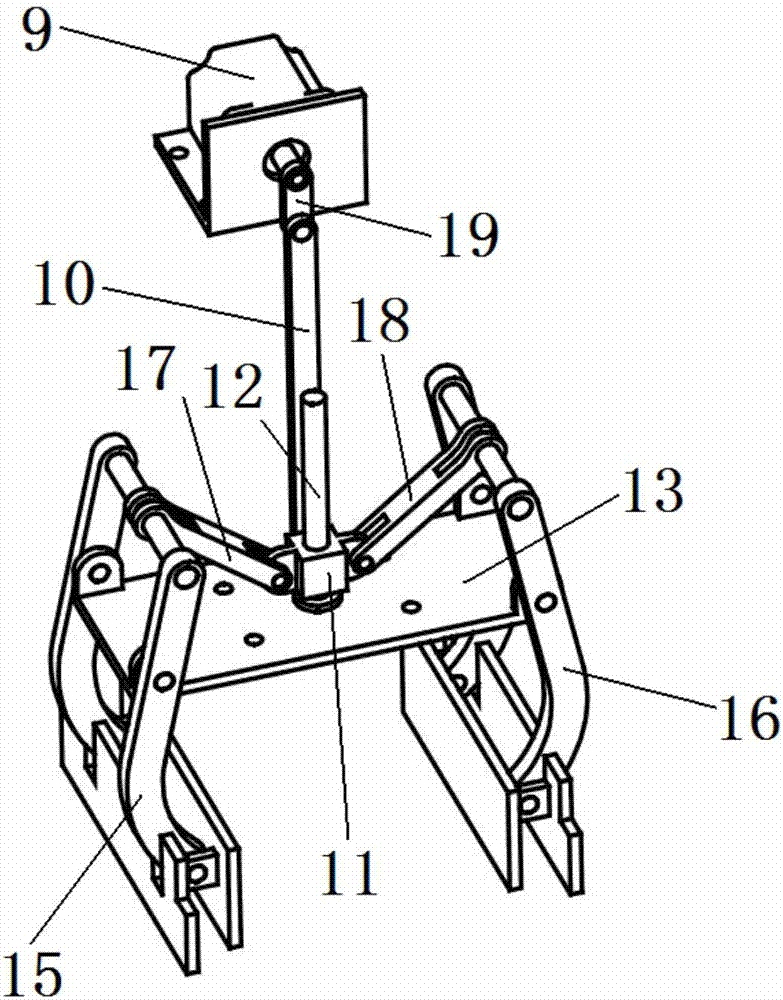

[0062] A fully automatic intelligent cutting all-in-one machine, including a strip cutting mechanism, a fixed manipulator and a twisting and cutting mechanism,

[0063]The strip cutting mechanism includes a first pulley 101, a second pulley 102, a third pulley 103, a fourth pulley 104, a fifth pulley 105, a sixth pulley 106, a line roller 153, and a first rotating shaft 111 , the second rotating shaft 112, the third rotating shaft 113, the fourth rotating shaft 114, the fifth rotating shaft 115, the first belt 121, the second belt 122, the third belt 123, the first cutting motor 131, the second cutting motor 132, The first guide block 141, the second guide block 142, the cutting line 154 and the strip cutting frame 155;

[0064] The first pulley 101 is installed on the first rotating shaft 111, the second pulley 102 and the sixth pulley 106 are all installed on the second rotating shaft 112, and the fifth pulley 105 and the line roller 153 are all installed on the fifth rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com