Positioning and centering combination clamping device

A technology of clamping device and centering cone, which is applied in the direction of positioning device, clamping device, clamping, etc., can solve the problems that the product is difficult to meet the product design requirements, the difference of positioning and clamping device is large, and the wall thickness is small. Achieve the effects of increasing overall rigidity, uniform wall thickness difference, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

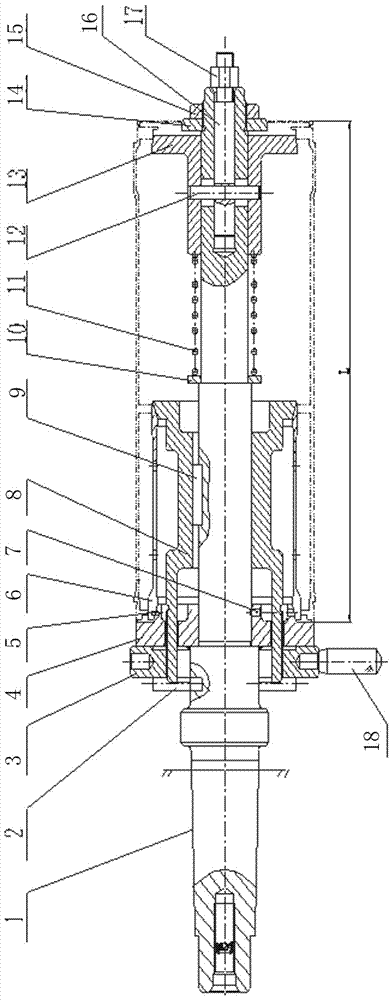

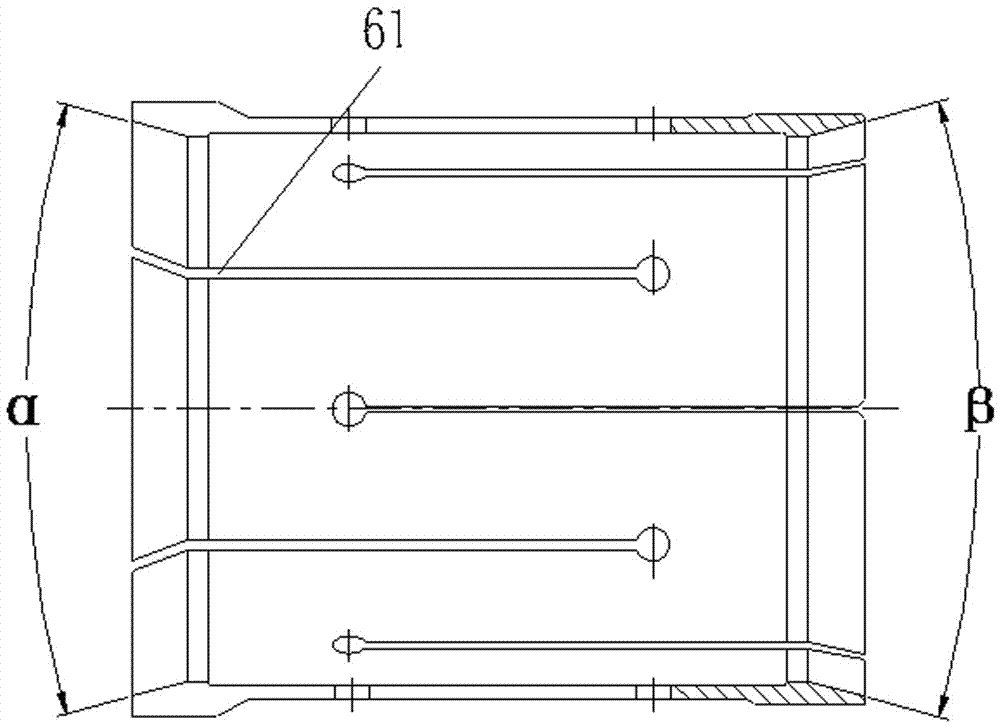

[0016] Such as figure 1 As shown, the present invention includes shaft 1, fixed pin 2, large nut 3, fixed cone 4, pin 5, expansion spring 6, set screw 7, movable cone 8, adjusting washer 10, spring 11, pin 12, fixed Heart cone 13, retaining ring 14, nut 15, mandrel 16, nut 17, handle 18. The fixed cone 4 and the movable cone 8 are arranged on the shaft, and the cone faces on the fixed cone 4 and the movable cone 5 are arranged oppositely. On axis 1, it is possible to move along axis 1. The front end of the movable cone 8 is provided with threads, and passes through the through hole on the fixed cone to be connected with the big nut 3 . The side wall of the big nut 3 is provided with a handle 18, which is convenient for the big nut 3 to rotate and fasten the workpiece to be processed. The two ends of expansion spring 6 are respectively placed on the conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com