Segmented expansion spring clamping device

A segmented, expanding spring technology, applied in the mechanical precision machining of long cylindrical thin-walled parts, segmented expanding spring positioning and clamping device field, can solve the problems of weak processing rigidity, and achieve improved processing accuracy and poor wall thickness. Uniform, reduced cutting vibration and deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

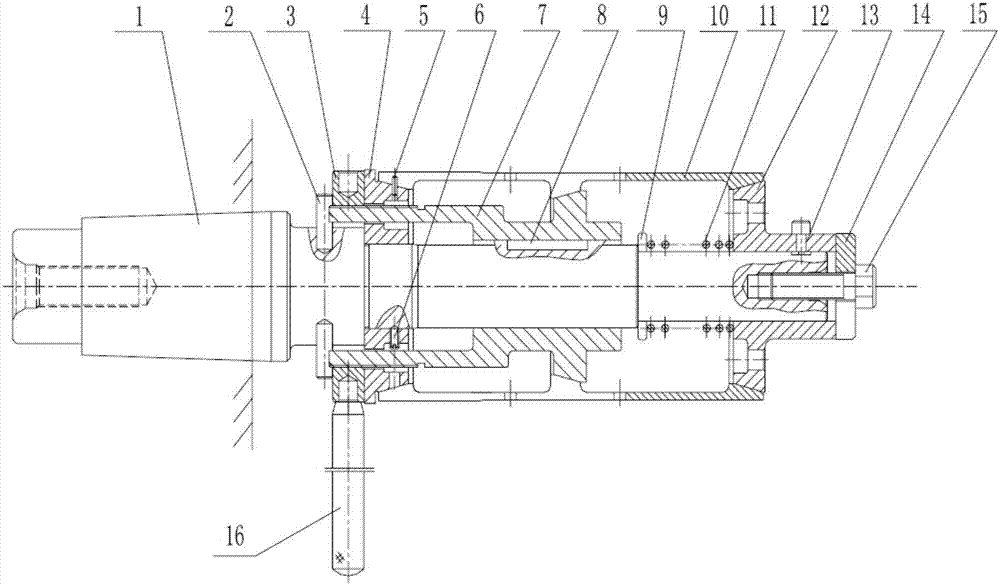

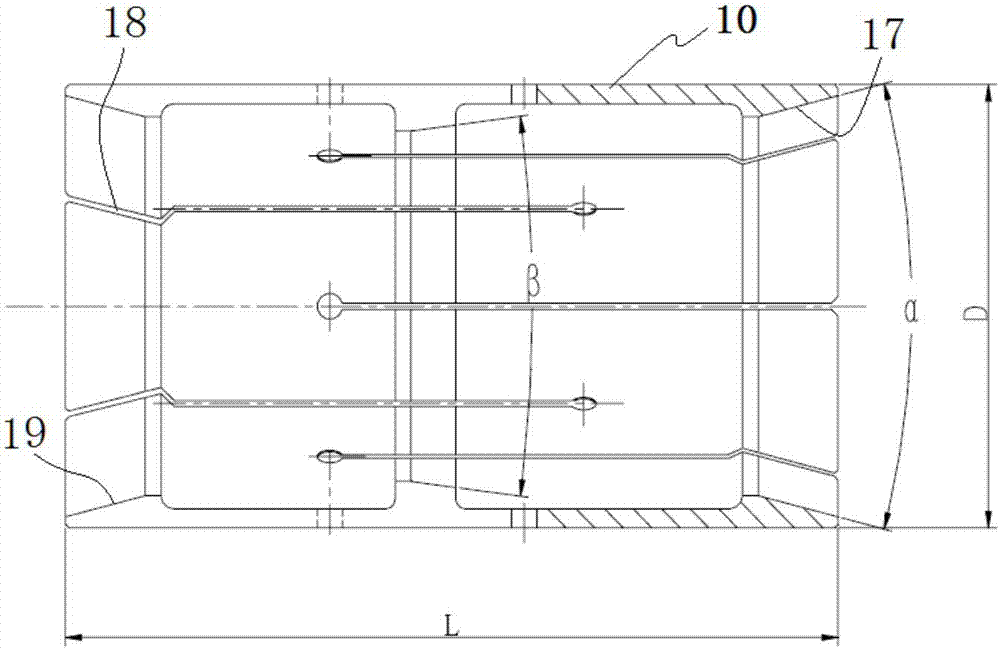

[0021] A bidirectional segmented expansion spring positioning and mid-section auxiliary support combined clamping device, such as figure 1 As shown, it includes main shaft 1, pin 2, nut 3, fixed cone 4, anti-rotation pin 5, stop screw 6, intermediate movable support body 7, key 8, adjusting washer 9, segmented expansion spring 10, spring 11 , Movable cone 12, limit screw 13, pressing plate 14, fastening screw 15, handle 16 and other parts. The structure is as follows: shaft 1 is connected with the inner hole of the machine tool spindle, and the fixture shaft is tightened with a long screw rod; after the 4 holes of the fixed cone are pressed into the shaft, it is fixed with the stop screw 6; one end of the segmented expansion spring 10 is placed on the fixed cone On the cone surface of the body, the opening groove on the expansion spring is aligned with the anti-rotation pin, and then the middle movable support body 7 is installed on the shaft, and the four bosses are aligned w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com