Microbubble gun with automatic fault detection and detection and control method

A fault detection and micro-bubble technology, applied in solid separation, flotation, etc., can solve problems such as micro-bubble gun blockage, slurry infiltration, and easy damage to nozzles, so as to avoid insufficient inflation, stabilize control, and ensure economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

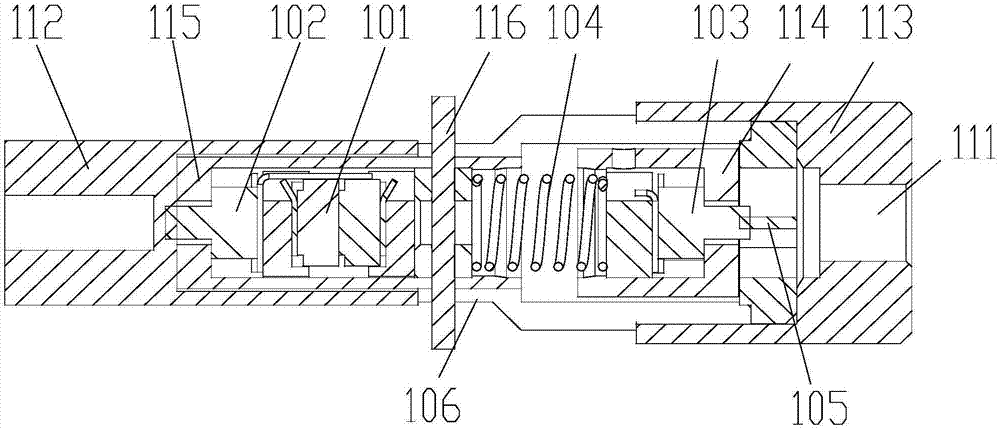

[0026] The technical content of the present invention will be further described in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, an automatic fault detection microbubble gun, the front end of the outer tube 1 is sealed and connected with the nozzle jacket 12, the nozzle jacket 12 is sealed and bonded with a wear-resistant nozzle 13, and the front end of the outer tube 1 is covered with a triangular bushing 10 , centering the inner rod 9, the rear end of the inner rod 9 is connected with the electronic control box 16, the front end of the inner rod 9 is connected with a plug 11, and the plug 11 and the wear-resistant nozzle 13 are tightly pressed to form a sealing effect; the outer tube 1. The rear end is sealed and connected with the diaphragm front sleeve 2. The diaphragm front sleeve 2 and the diaphragm rear sleeve 3 are connected by a plurality of bolts 20. Ring grooves are set on the bonding surfaces of the diaphragm front sleeve 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com