Novel antirust valve

A valve, a new type of technology, applied in the field of daily life, can solve the problems of handle wear, valve damage, rust spots, etc., to reduce the entry of water, promote health, and prevent rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

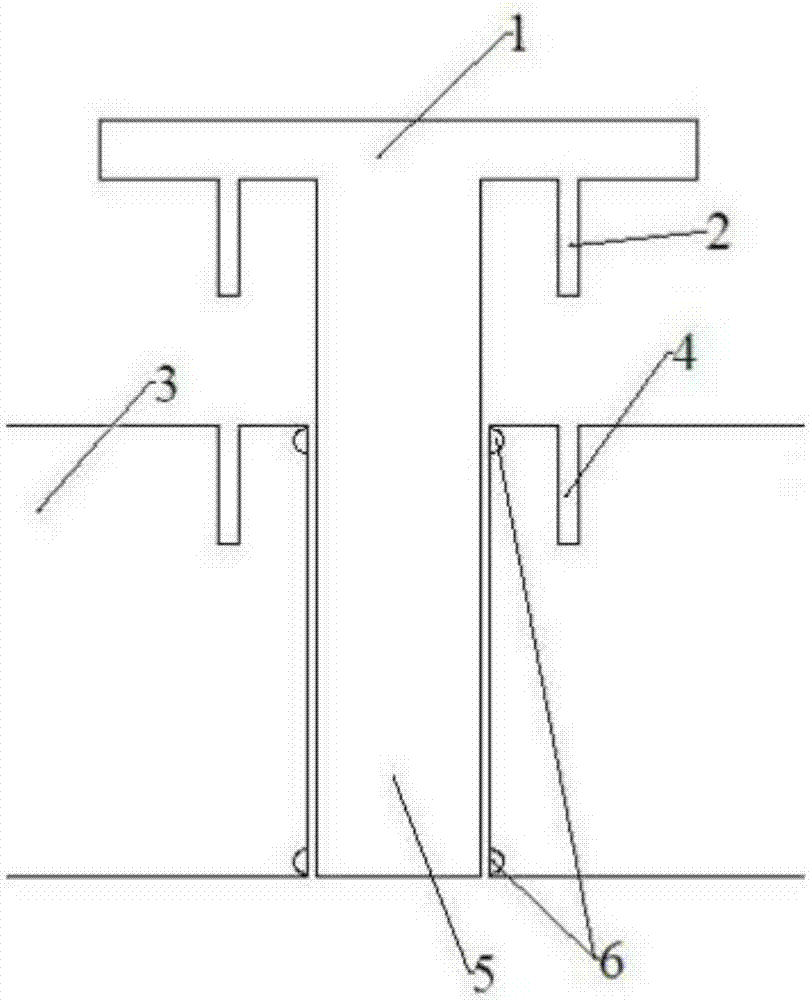

[0020] like figure 1 As shown, a new type of anti-rust valve in this embodiment includes a valve body 3 and a handle, the valve body 3 includes a valve cavity, a valve wall and a valve body opening, and the handle turntable 1 is provided with a circular ring on the side close to the valve body opening. Protrusion 2, a groove 4 is provided on the top of the valve body 3 opposite to the circular ring protrusion 2. The groove 4 matches the annular projection 2 . After the handle is rotated towards the valve, the annular protrusion 2 is snapped into the groove 4, thereby closing the space between the handle and the valve opening, reducing the entry of moisture and preventing rust.

[0021] The inner wall of the valve body opening is provided with an annular storage cavity 6, and there are two storage chambers 6, which are respectively located at the upper and lower ends of the valve body opening. An easily absorbent material is placed in the storage cavity 6, which can prevent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com