Method for controlling high temperature stope face operating region environment temperature by means of cold wind separation curtain

A technology for mining working face and working area, which is used in mining equipment, earth-moving drilling, mine/tunnel ventilation, etc. It can solve the problems of poor cooling effect, high energy consumption, and large temperature difference between the inlet and return air of the working face.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

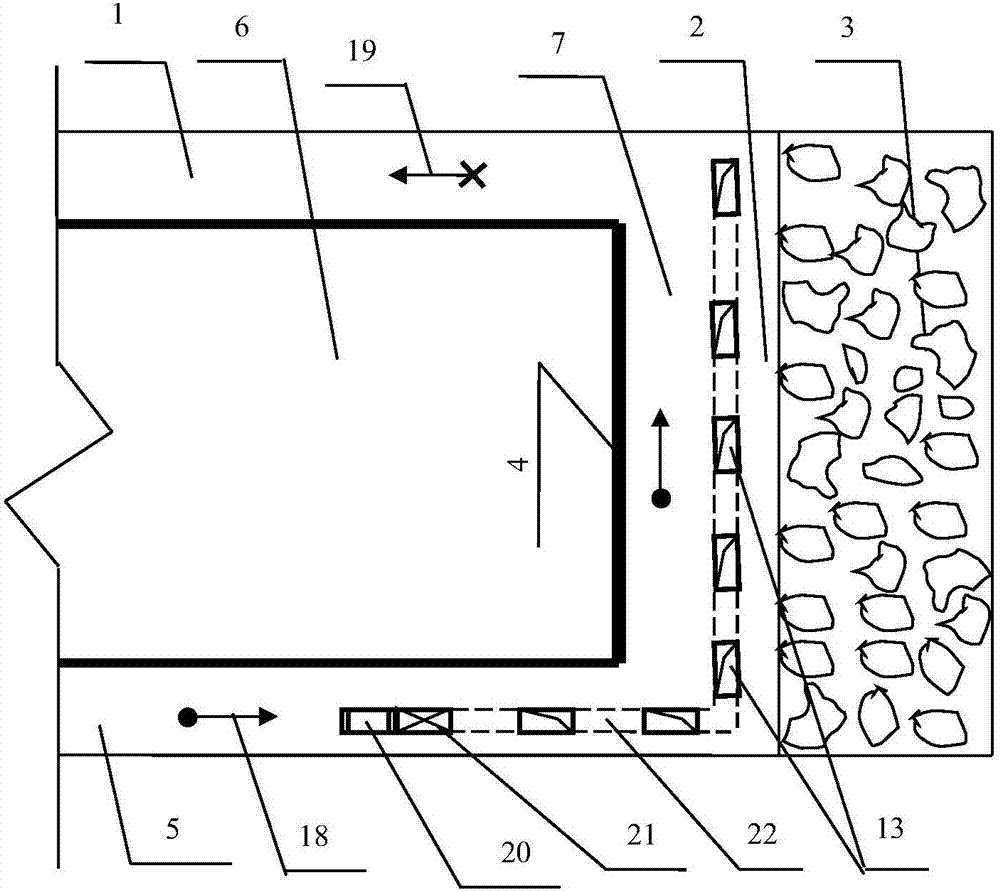

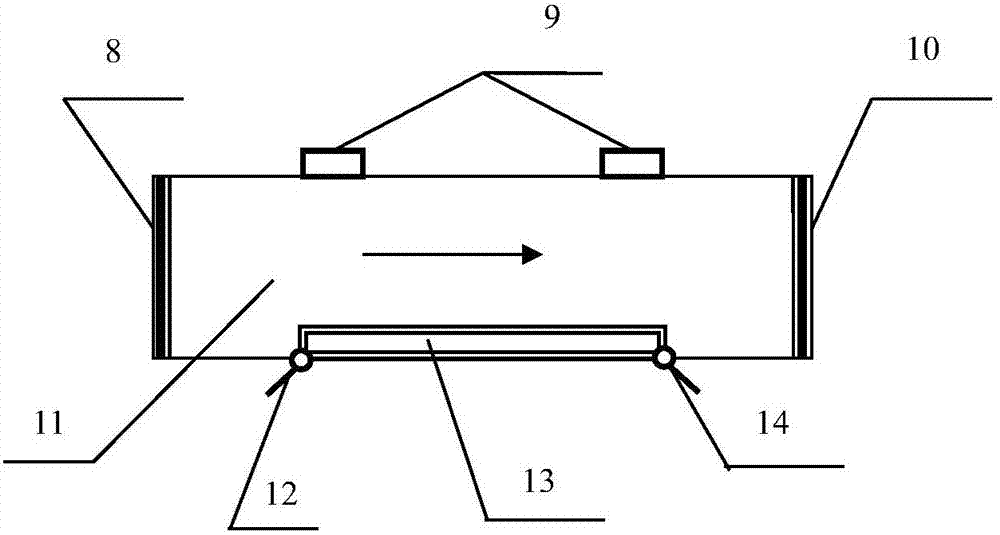

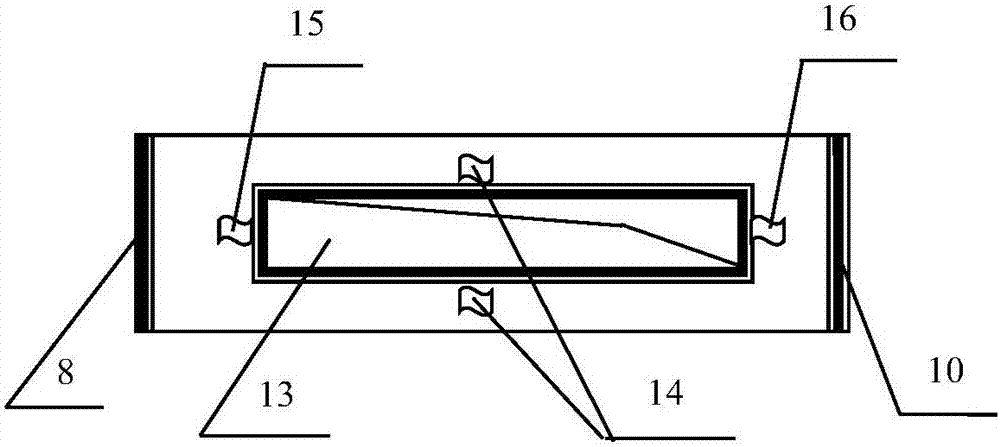

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Mechanism of cold air tent to control heat damage in working area of mining face: The generation of heat damage in mining face is an extremely complicated process. Through on-site heat damage investigation and analysis, it is found that the high-temperature heat sources that cause heat damage mainly come from high-power mining equipment and continuously broken high-temperature coal and rock mass. In order to eliminate the heat damage caused by these high-temperature heat sources, in the original cooling design, the The entire recovery space is used as the cooling load calculation range, and the required cooling capacity of the recovery working face is released in the air inlet lane. Although the cooling process is relatively simple in this way, it will cause problems such as large temperature difference between the inlet and the return air on the working face,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com