Assembled heat-preservation aerated concrete composite wall plate and manufacturing method thereof

An air-entrained concrete slab and air-entrained concrete technology, which is applied in the direction of architecture, building components, and building structures, can solve the problems of high wind load, easy cracking, easy collision of air-entrained concrete, development and application constraints of air-entrained concrete wall panels, etc. problems, to achieve the effect of reducing the risk of poor construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the patent of the present invention is described in detail.

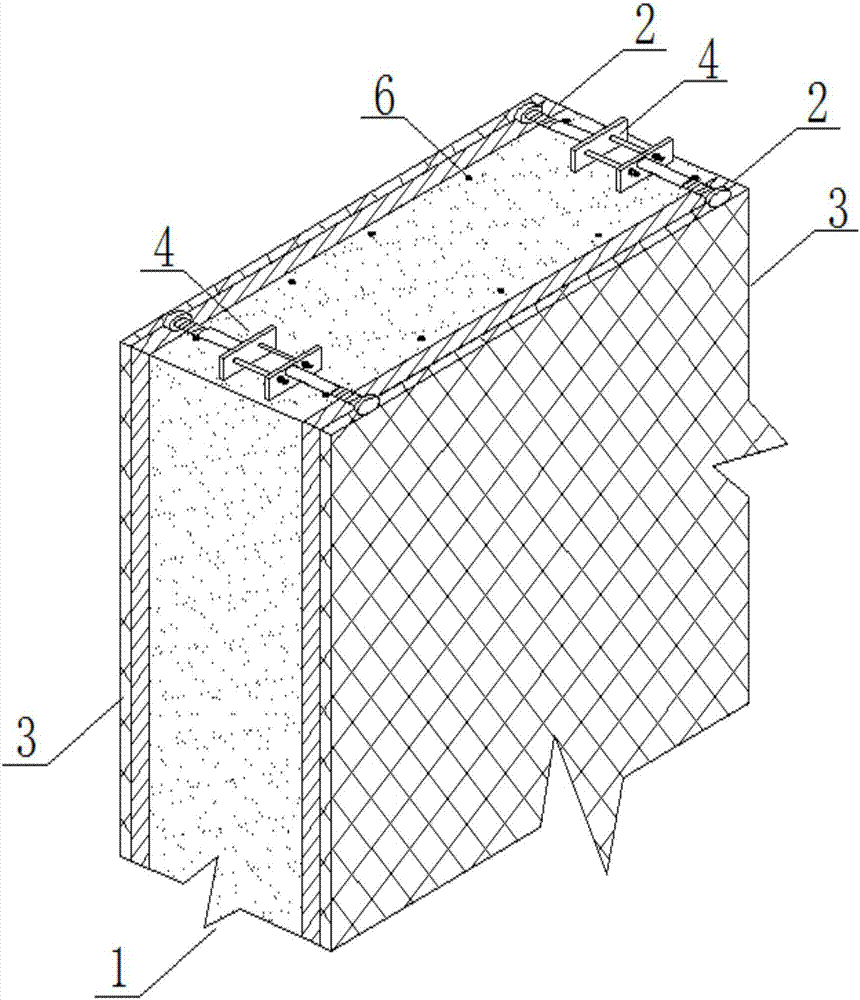

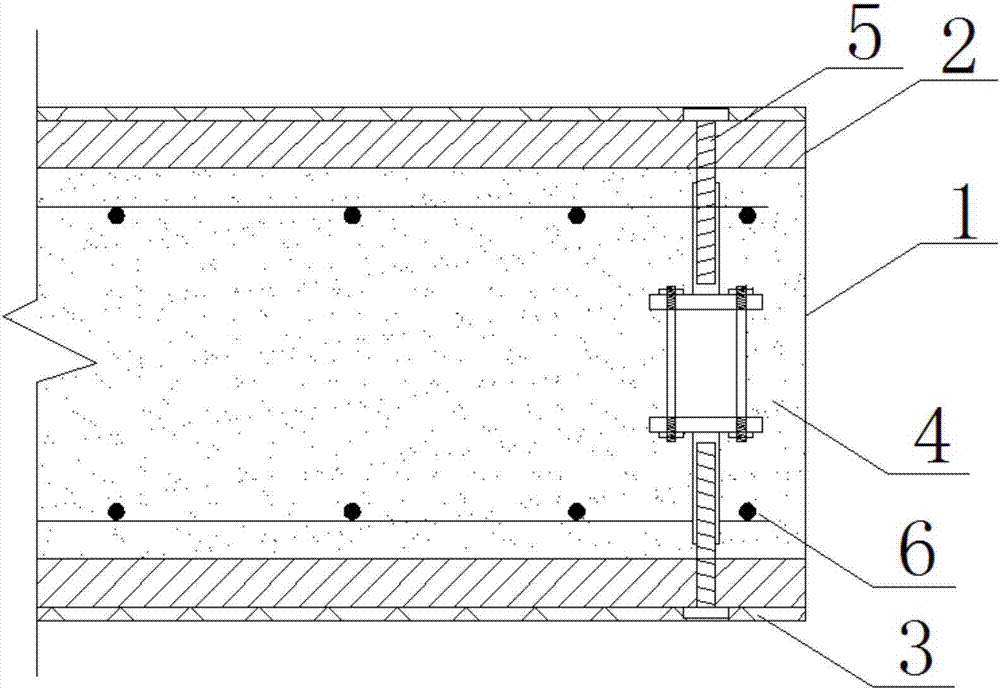

[0028] Such as figure 1 As shown, the patent of the present invention is an assembled air-entrained concrete composite wallboard, including air-entrained concrete (1), cement fiber board (2), exterior finish layer (3) and embedded parts (4). The weight level of the air-entrained concrete slab is B03, because the lighter the weight, the more pores, and the better the thermal insulation performance.

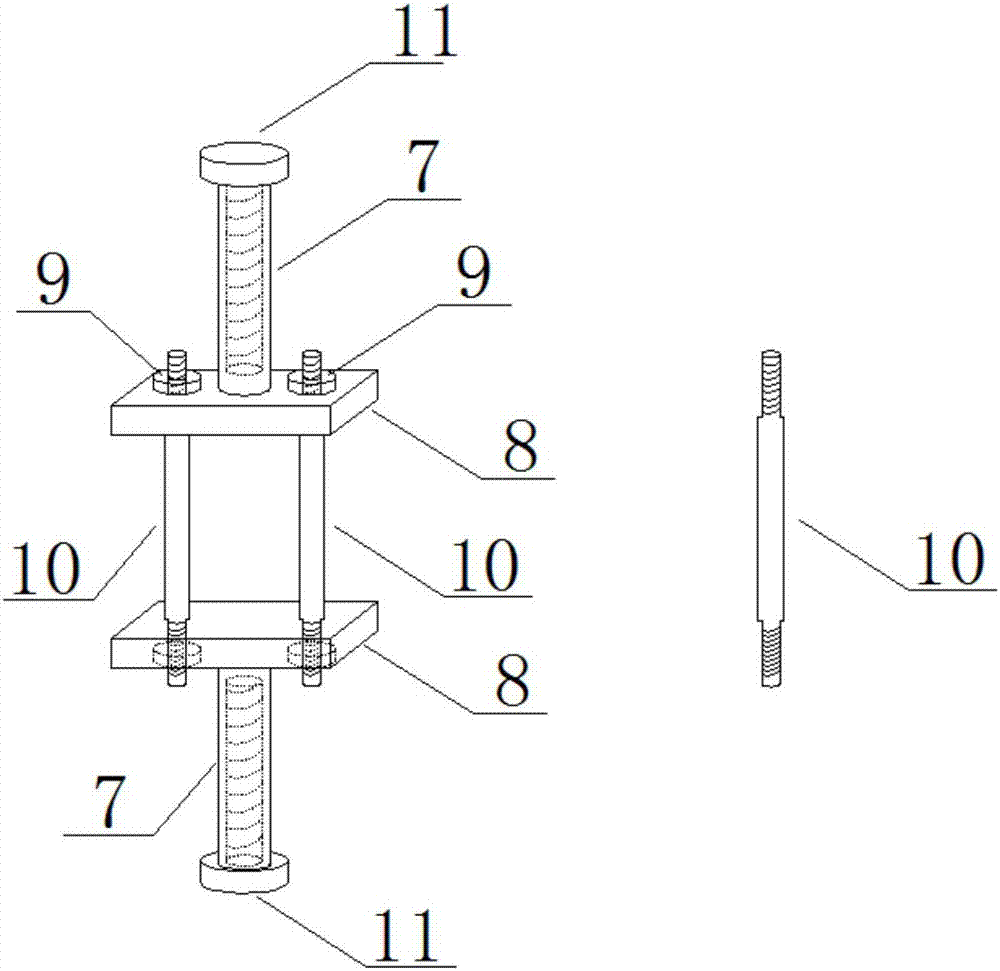

[0029] The embedded parts (4) consist of bolts 1 (11) with external threads, steel sleeves (7) with internal threads, steel plates with holes at both ends (8), FRP flanges with internal threads (9 ), FRP tendons (10) with external threads at both ends.

[0030] The method for preparing the assembled aerated concrete composite wall panel is as follows:

[0031] Step 1: Make embedded parts (4).

[0032] A set of embedded parts (4) includes two bolts 1 (11) with ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com