Ventilated cooling rainproof high-speed motor of electric bicycle

An electric bicycle, ventilation and cooling technology, applied in the direction of electric components, cooling/ventilation devices, electrical components, etc., can solve the problems of reduced overall heat dissipation area, increased high-frequency additional loss, and reduced efficiency, so as to extend the mileage and The effects of climbing ability, reducing discharge current and improving working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

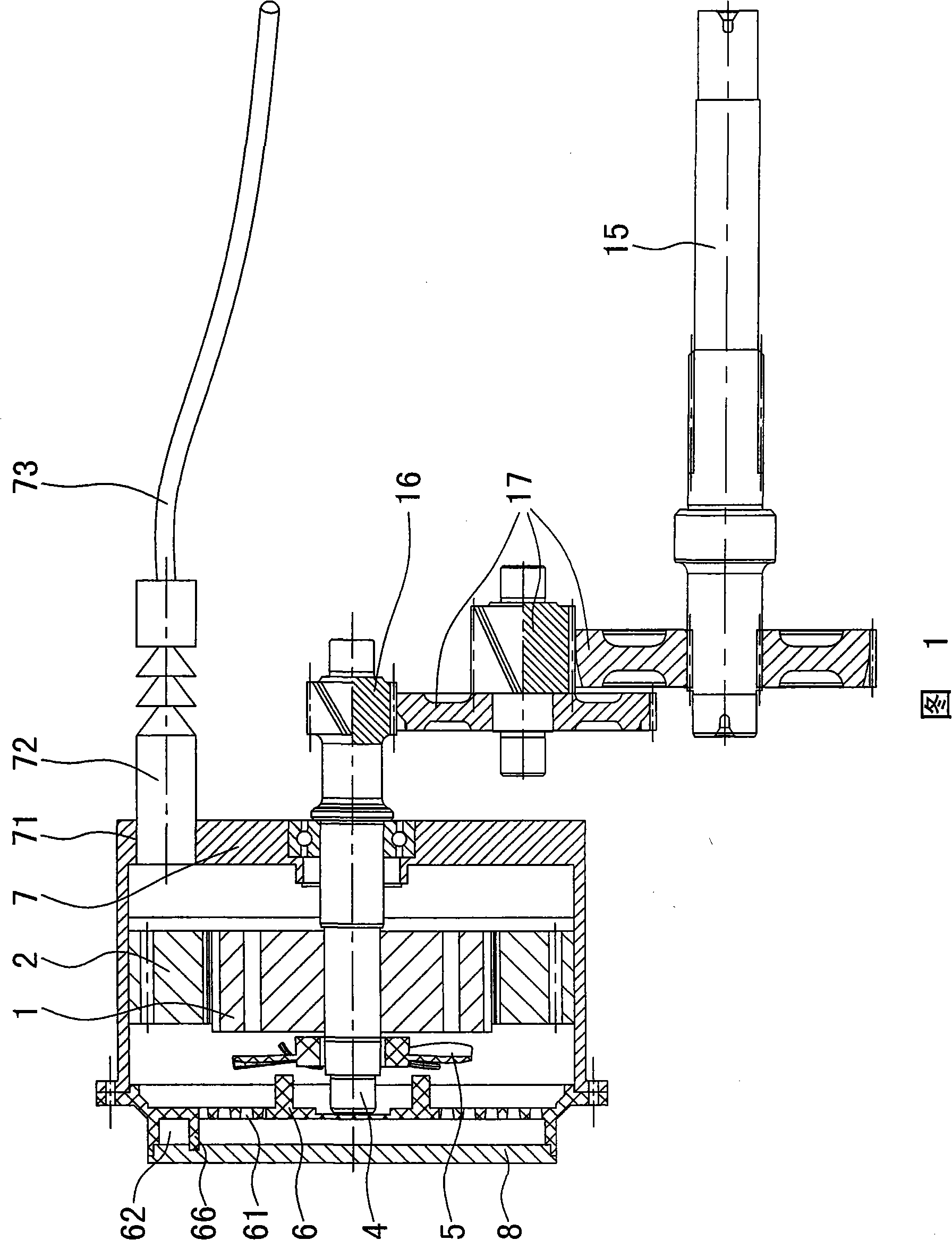

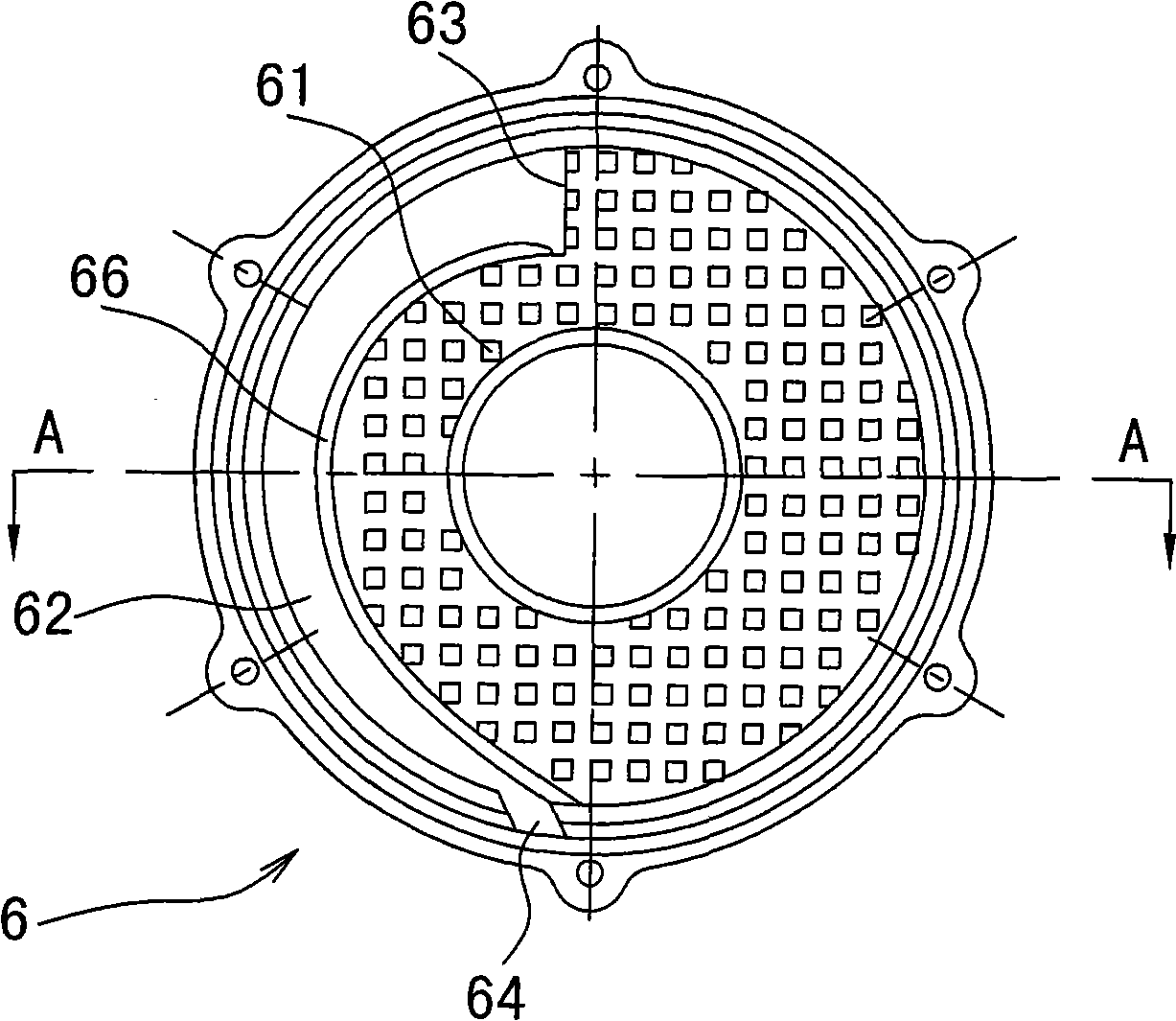

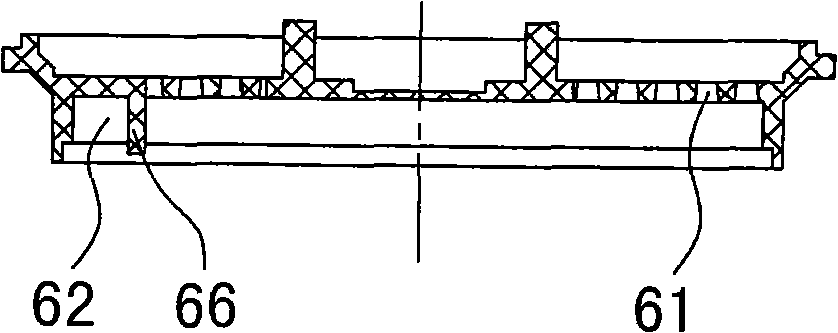

[0017] The invention discloses a ventilation, cooling and rainproof high-speed motor for an electric bicycle. As shown in Figure 1, there are a motor rotor 1 and a stator 2, a casing outside the stator, a casing connecting end cover 6 and a gearbox connecting cover 7, and the casing It can be integrated with the connecting cover 7. The motor shaft 4 of the rotor is installed in the end cover 6 and the connecting cover 7. The motor shaft 4 is formed with a speed change gear 16. The speed change gear drives the output shaft 15 through the bridge gear set 17, and the output shaft drives The electric bicycle hub has a box outside the gear transmission mechanism. Its main technical features are that the gearbox connection cover 7 is formed with an air suction port 71, the fan blade 5 is installed on the motor shaft 4, and the end cover 6 is formed with a ventilation hole 61 and Exhaust duct 62, such as figure 2 As shown, the exhaust duct 62 has an air inlet 63 and an air outlet 64,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com