Bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag

A technology of high lead slag and reduction furnace, applied in the field of bottom side blowing molten pool reduction furnace and molten pool reduction furnace, can solve the problems of reducing lead content in slag, high lead content in slag layer, energy waste, etc., so as to reduce slag content Lead rate, improve direct yield, and facilitate the effect of converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

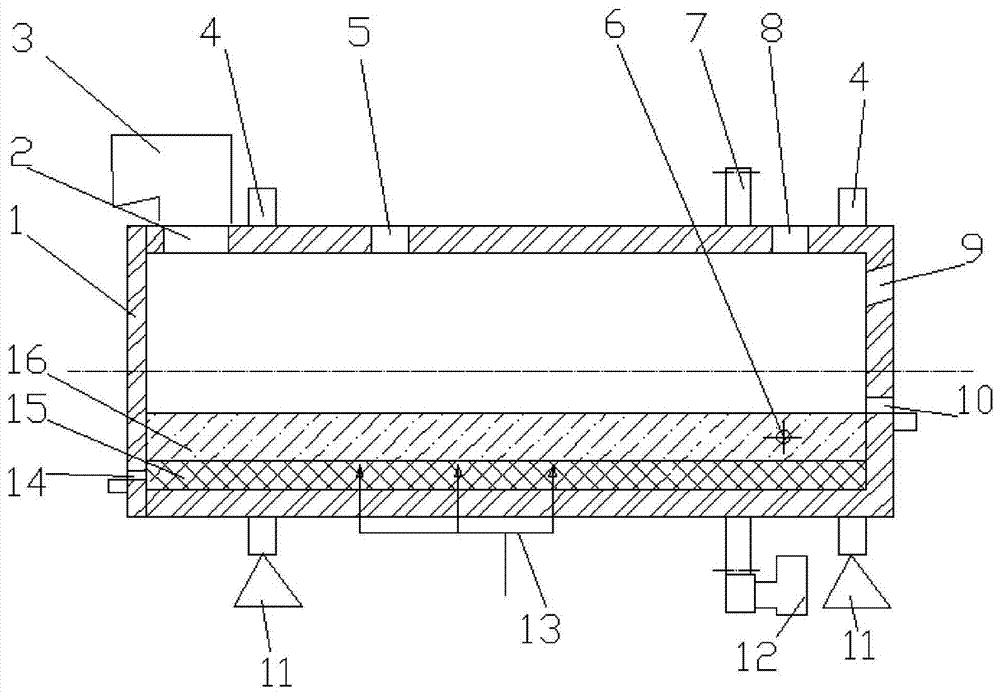

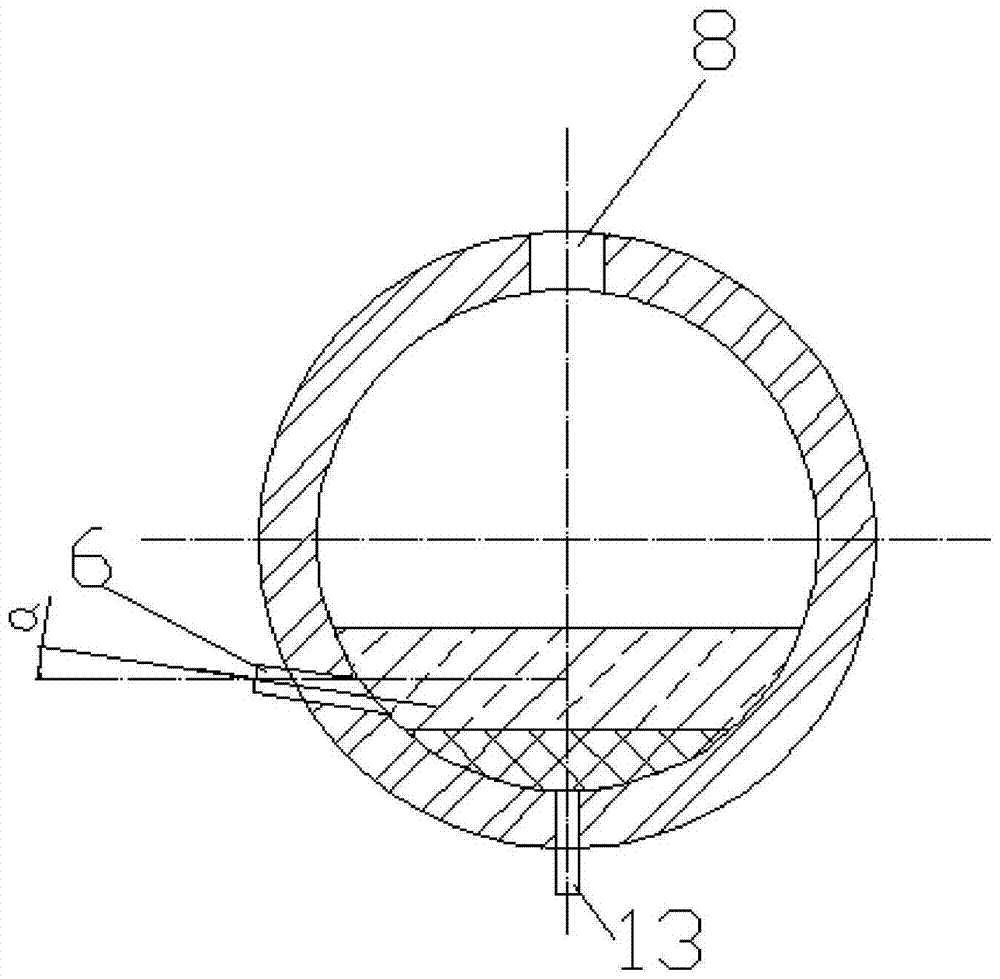

[0021] Embodiment 1: see figure 1 , 2 , a bottom-side blowing molten pool reduction furnace for liquid high-lead slag, comprising a cylindrical horizontal furnace body and support seats arranged at the left and right ends of the furnace body, and the outer walls of the left and right ends of the furnace body are fixed There is a rolling ring, which is rotatably installed on the support seat through the rolling ring, and is driven by the driving device to realize the rotation. The top of the furnace body is sequentially provided with a smoke outlet, a first feeding port and a The second charging port, the smoke outlet is located at the left end of the furnace body, the second feeding port is located at the right end of the furnace body, the upper part of the right end side plate is provided with a burner port, the lower part of the right end side plate is provided with a slag outlet, the left end side of the furnace body The bottom of the plate is provided with a direct lead o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com