Method for preparing bio-charcoal granular organic fertilizer

A technology of biomass charcoal particles and biochar, applied in organic fertilizers, animal carcass fertilizers, fertilization devices, etc., can solve the problems of unfavorable transportation and use, and achieve good slow-release function and the effect of promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

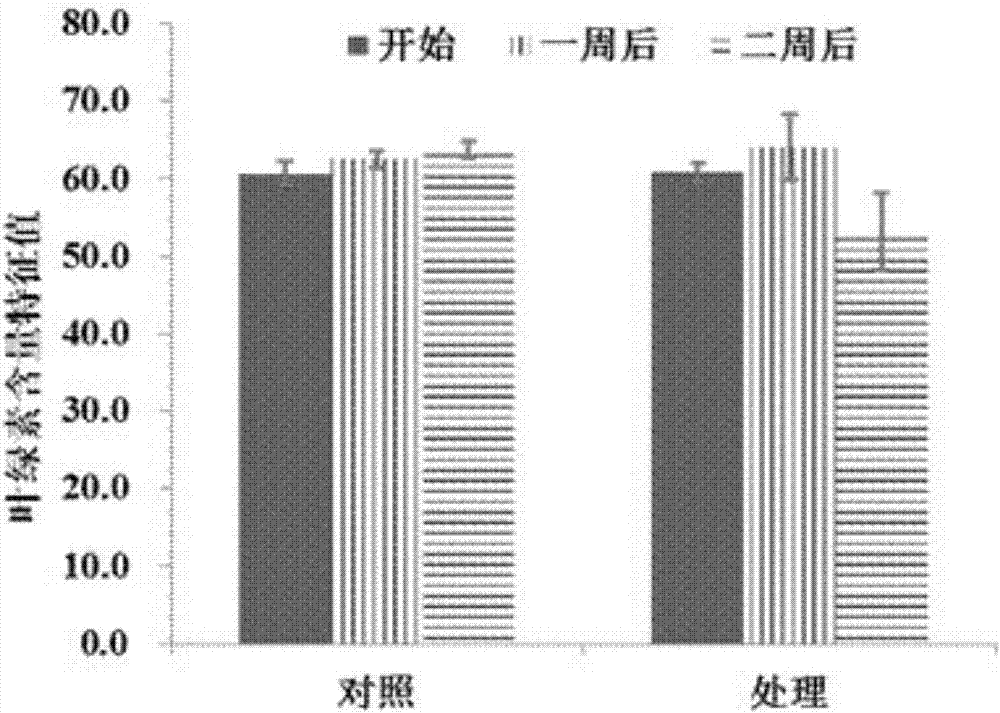

[0018] Biochar granulated organic fertilizer formula: 50% biochar, 30% organic fertilizer, 20% oyster shell powder. Prepare the biochar granulated organic fertilizer from the above raw materials according to the following method: pass the raw materials through a 60-mesh sieve respectively, add them to the mixer, stir at a speed of 60 times / min for 10 minutes, mix well, and add water to the mixed fertilizer powder The mass ratio of water and solid mixed raw materials is 0.7:1. After stirring evenly, it is sent to a kneading granulator, and the granulated fertilizer is sent to a dryer for drying at 60°C, and the dried raw Substance Charcoal Granulated Organic Fertilizer Finished for Plant Growth Tests in Soilless Cultivation.

[0019] (1) Basic physical and chemical properties test

[0020] The results show that the pH value of the prepared biochar granulated organic fertilizer is basically between 6.61-6.75, which is a neutral level; the EC of the particles is 29.4-34.9mS.cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com