Production process for preventing pre-deformation of ceiling product

A production process and pre-deformation technology, applied in metal processing, upper structure, upper structure sub-assembly, etc., can solve problems such as complex process of automobile roof, weak market competitiveness, and low production efficiency, so as to achieve ingenious design and prevent Unglue phenomenon, improve the effect of product coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

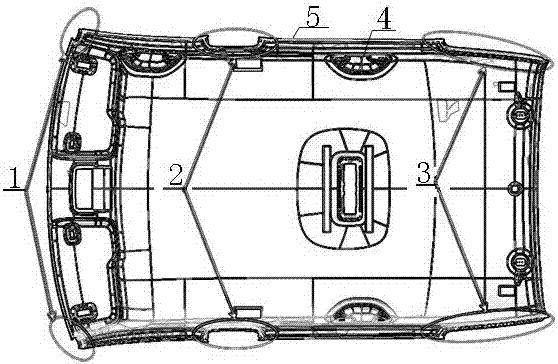

[0021] Refer to attached Figure 1-8 , the production process of roof products to prevent pre-deformation, roof product design includes A-pillar area 1, B-pillar area 2, C-pillar area 3 and handle hole area 4, roof product 5 and A-pillar plastic parts 6, B-pillar plastic parts 7 or The contact surface of C-pillar plastic part 8 is surface A, and the opposite surface of ceiling A is surface C. The ceiling product 5 needs to be designed to prevent pre-deformation before production.

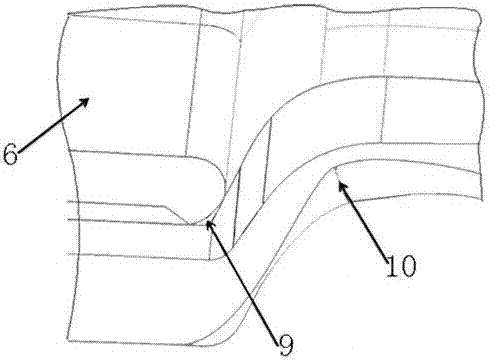

[0022] 1) In the A-pillar area 1, the contact position 9 of the A-pillar plastic part 6 and the A-side of the ceiling product 5 is artificially designed so that the A-pillar plastic part 6 and the A-side of the ceiling product 5 have an interference of 0.3 mm; at the R corner of the C-surface in this area 10 The roof product 5 is raised by 1.5mm;

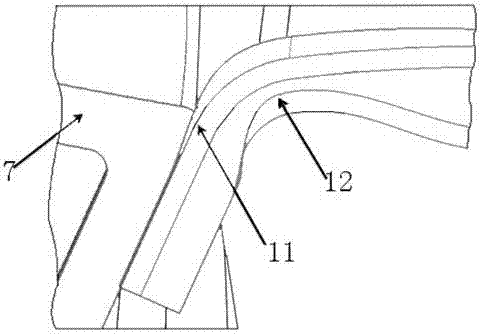

[0023] 2) In the B-pillar area 2, the contact position 11 of the B-pillar plastic part 7 and the surface A of the ceiling product 5 is artificially desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com