Brick making machine capable of automatically detecting production quantity

An automatic detection and brick making machine technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of inaccuracy, time-consuming and laborious production of numbers, etc., and achieve the effect of saving raw materials, manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

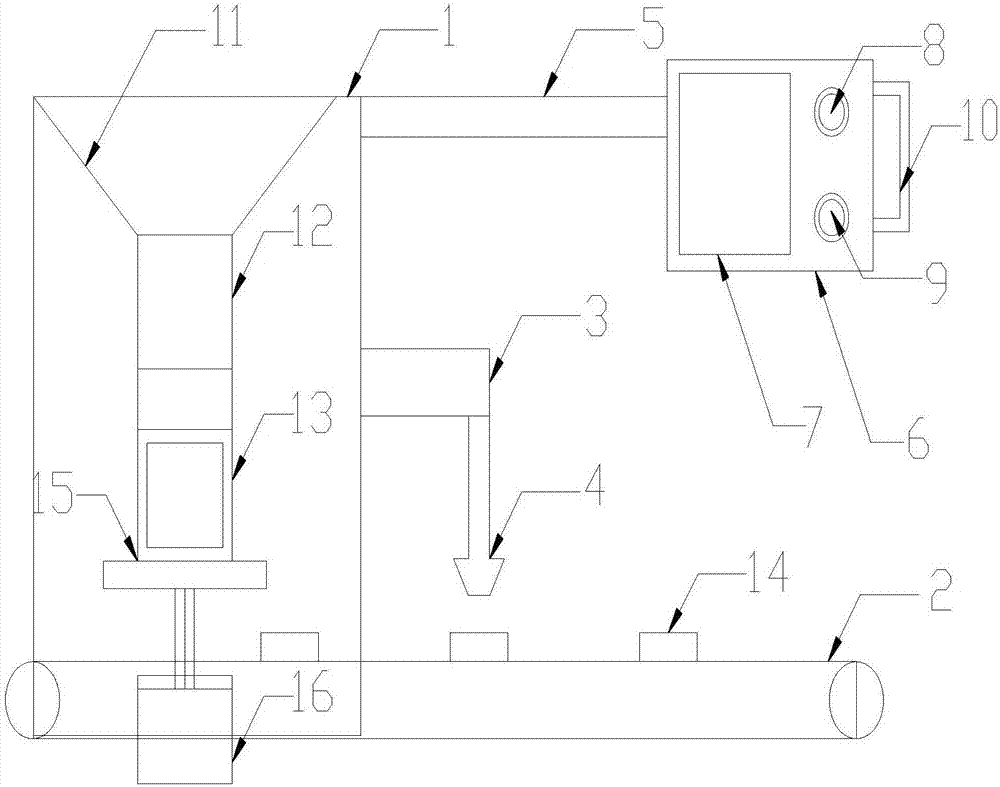

[0015] Such as figure 1 As shown, the present invention provides a brick making machine that automatically detects the production quantity, including a brick making machine main body 1, a conveyor belt 2, a quantity detector 4 and a control cabinet 6. The main body 1 of the brick making machine is used to make brick bodies 14 from brick making raw materials. The bottom end of the main body 1 of the brick making machine is fixedly connected with the conveyor belt 2, and the conveyor belt 2 spreads out the finished brick body 14 evenly from the main body of the brick making machine. One side of the main body 1 of the brick making machine is fixedly provided with a support rod 3 , and the support rod 3 is fixedly connected with a quantity detector 4 . The top of the main body 1 of the brick making machine is fixed with a connecting rod 5. The connecting rod 5 is a hollow metal tube through which wires can be threaded. The connecting rod 5 is connected to the control cabinet 6. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com