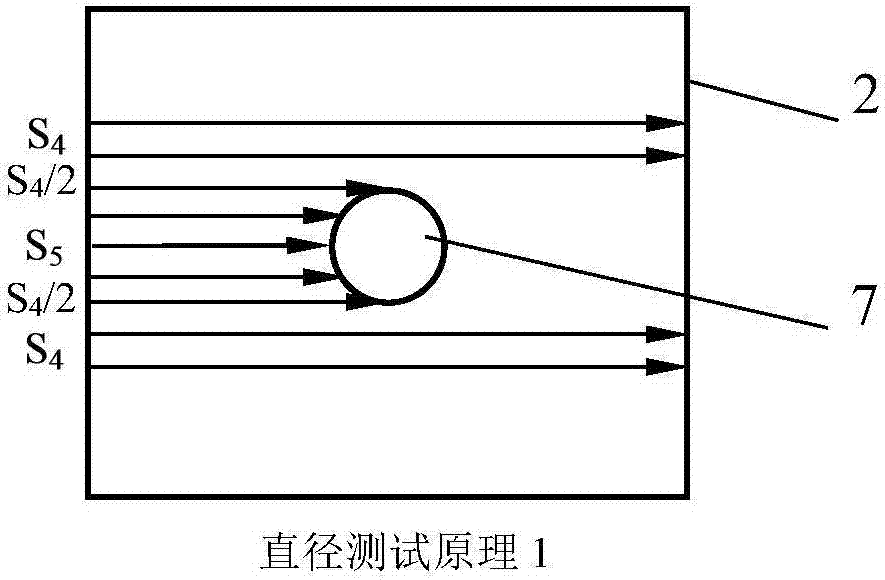

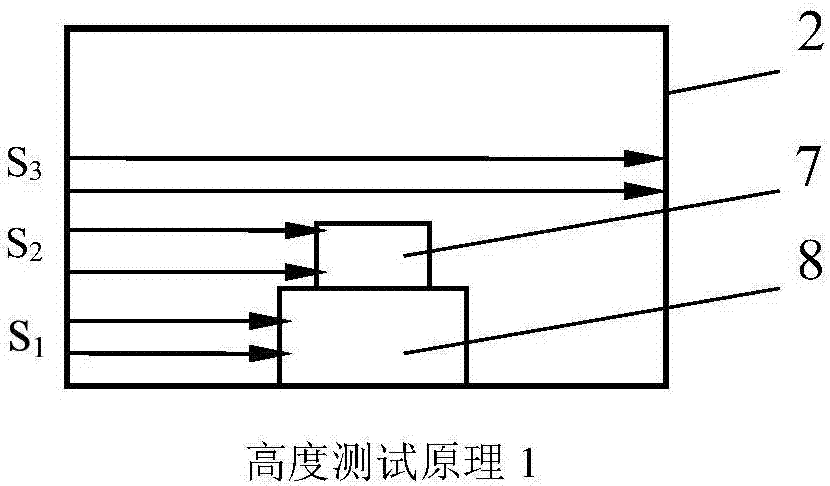

System for measuring sample quality and dimensions in freeze-thaw cycle process

A freeze-thaw cycle and test system technology is applied in the field of test systems to achieve the effects of convenient operation, accurate data and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Turn on the computer processing system and reset all data to zero. Open the box cover 6, place the sample in the middle position on the weighing test bench 7, cover the box cover 6, start the temperature control system 5, and when the temperature reaches the set temperature, turn on the cylindrical laser range finder 3,4, At the same time, the dynamic data acquisition instrument will automatically collect the sample quality and size data, and send them to the computer processing system for processing in time to achieve the purpose of real-time monitoring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com