Artificially excavated riding well and construction method thereof

A construction method, the technology of riding a well, is applied in the field of inspection wells, which can solve the problems of long construction period, unfavorable construction for workers, and large engineering volume, and achieve the effects of ensuring construction quality, convenient drainage, and less water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

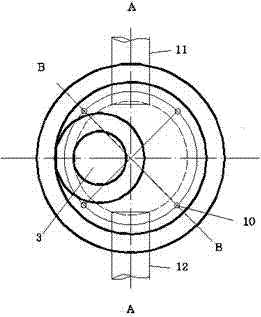

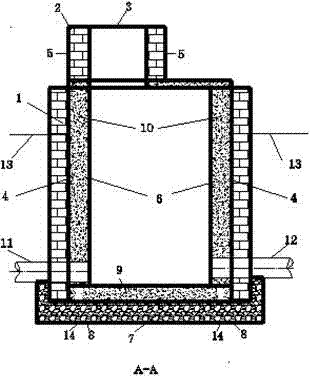

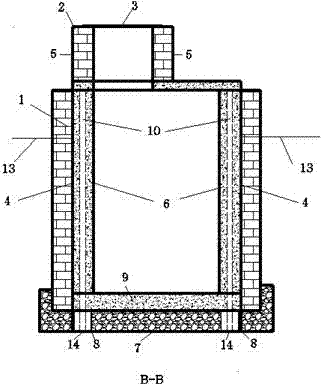

[0021] Such as Figure 1 to Figure 3 As shown, a manual excavation riding well includes a brick wall 1, a steel bar 13 is inserted in the brick wall 1, a brick well circle 2 is arranged above the brick wall 1, and a brick well circle 2 is placed above the brick wall 1. A manhole cover 3 is provided, a waterproof cement mortar layer 4 is powdered on the inside and outside of the brick well circle 2, a galvanized wire mesh 5 is arranged on the outside of the brick well circle 2; a reinforced concrete well circle 6 is arranged on the inside of the brick retaining wall 1, There is a graded crushed stone 7 behind the brick wall at the bottom of the horse-riding well and under the pipeline, and a corrugated pipe 8 is arranged inside the graded crushed stone 7, and the bottom and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com