Sludge heating and drying system and method thereof

A technology of heating and drying sludge, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., and can solve the problem of no corresponding increase in sewage treatment rate, sludge discharge and stacking pollution sources, etc. problem, to achieve the effect of good sludge quality, easy drying treatment, and improved removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

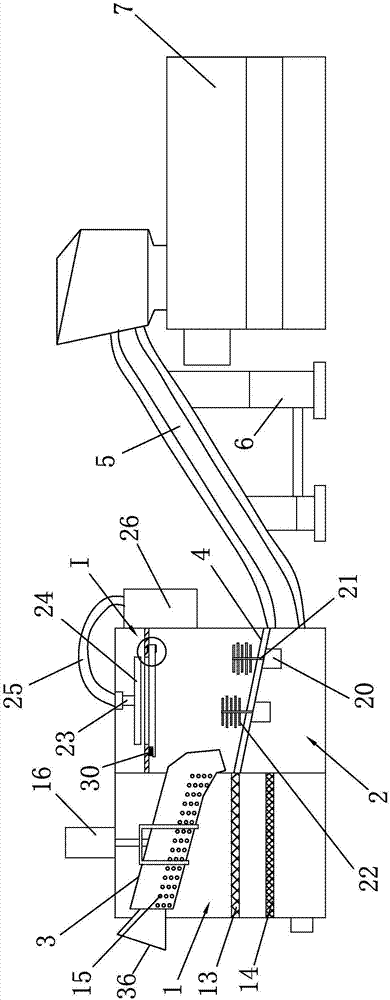

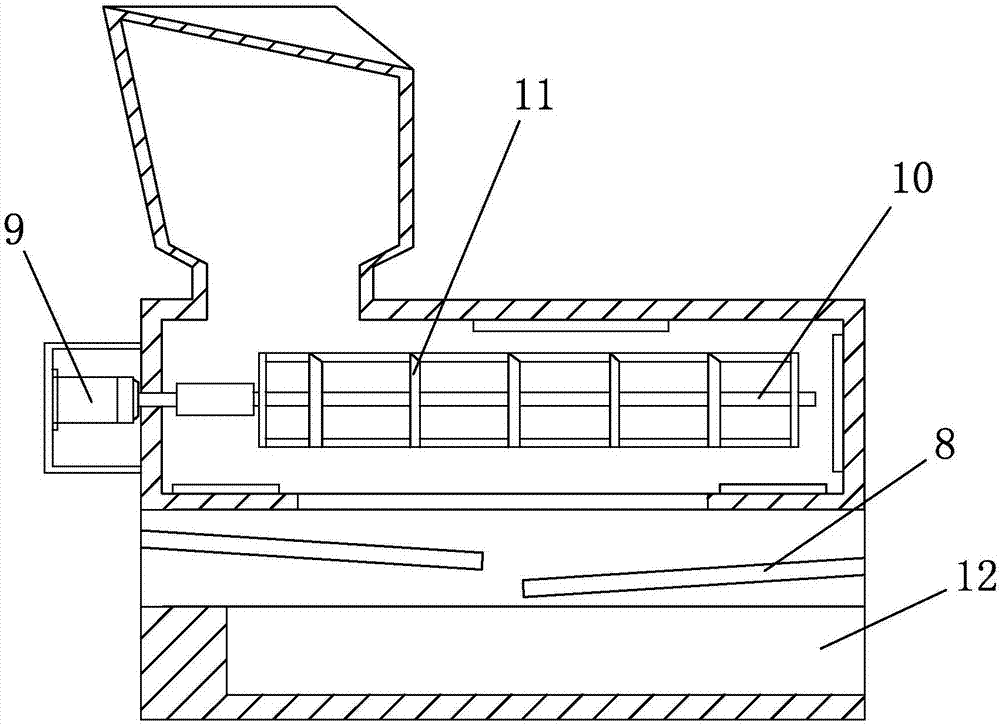

[0040] like Figure 1 to Figure 5 Shown is a sludge heating and drying system of the present invention, including a pretreatment mechanism, a transmission mechanism and a drying mechanism. The pretreatment mechanism is connected to the drying mechanism through the transmission mechanism. The pretreatment mechanism includes a dehydration chamber 1 and a dispersion chamber 2. Chamber 1 and dispersing chamber 2 are arranged in sequence from left to right.

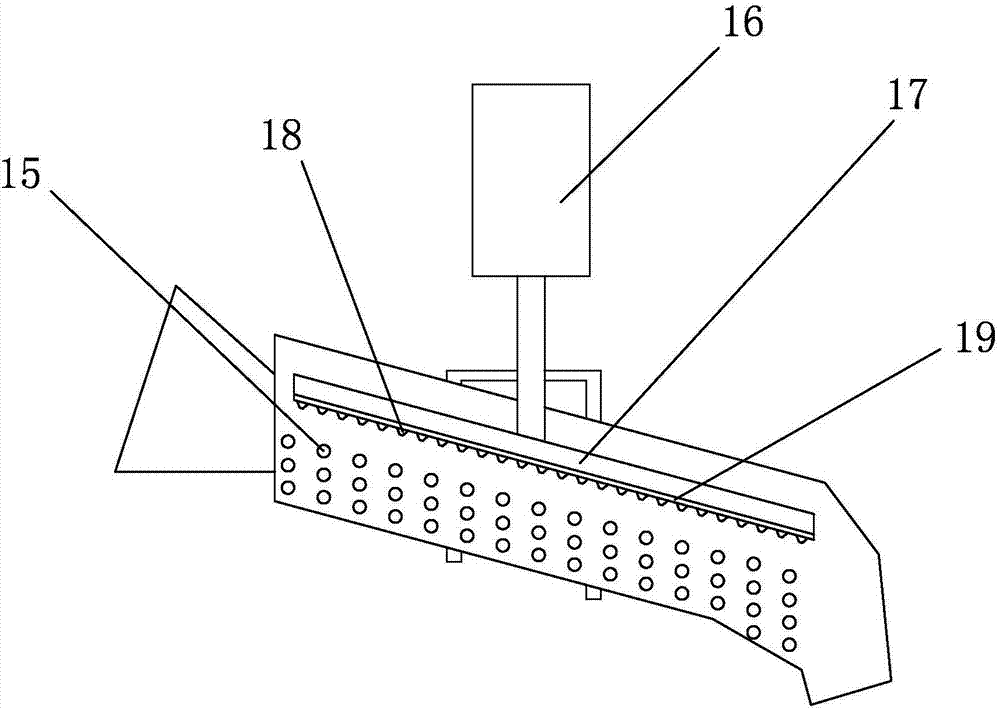

[0041] The dehydration chamber 1 is provided with a dehydration cylinder 3 and an extruding device, the extruding device is arranged in the dehydration cylinder 3, and the lower side wall of the dehydration cylinder 3 is uniformly provided with water leakage holes 15, and the water leakage holes 15 are all provided with water-permeable membranes. The left end of the cylinder 3 is provided with a left seal ring, and the feed hopper 36 extends into the dehydration cylinder 3 through the left seal ring. The design can facilitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com