Sludge stirring equipment adopting circulation type stirring processing

A mixing equipment and circulating technology, which is applied in sludge treatment, multi-stage water treatment, water/sludge/sewage treatment, etc., can solve problems such as difficulty in ensuring uniform addition of powder, loud equipment noise, and equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

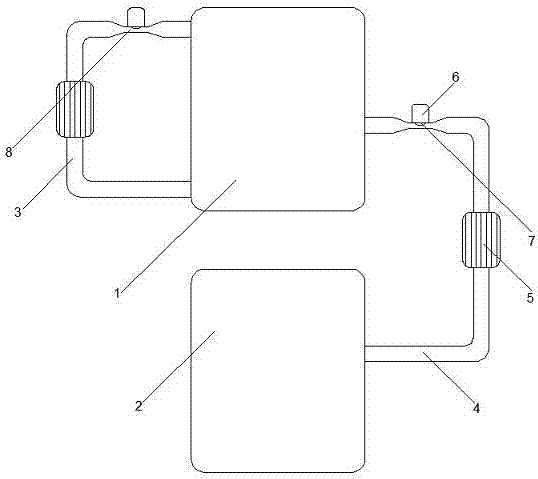

[0015] Such as figure 1 A kind of sludge agitation equipment that adopts circulation stirring treatment is shown, which includes a first treatment chamber 1 and a second treatment chamber 2, and the first treatment chamber 1 is provided with a second treatment chamber extending from its upper end to its lower end. A diversion pipeline 3, the first treatment chamber 1 and the second treatment chamber 2 are connected through a second diversion pipeline 4, and a diversion pump is respectively arranged in the first diversion pipeline 3 and the second diversion pipeline 4 5. The first flow guide pipe 3 and the second flow guide pipe 4 are respectively provided with a powder feeding device, which includes a powder feeding tank 6 arranged outside the first flow guide pipe 3 and the second flow guide pipe 4 , and the powder feeding nozzle 7 extending to the inside of the first flow guide pipe 3 and the second flow guide pipe 4 via the powder feed tank 6 .

[0016] As an improvement o...

Embodiment 2

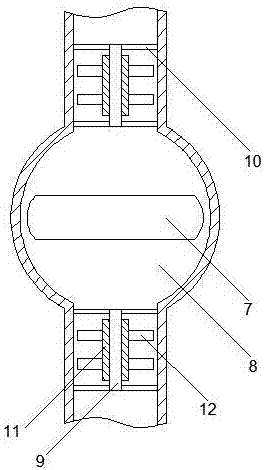

[0020] As an improvement of the present invention, such as figure 2 As shown, among the first flow guide pipe 3 and the second flow guide pipe 4, the front end and the rear end of the powder adding area 8 are respectively provided with turbulence devices, which include along the first flow guide pipe 3 and The spoiler shaft 9 extending axially in the second guide duct 4, the spoiler shaft 9 is connected to the inner walls of the first guide duct 3 and the second guide duct 4 through a plurality of support rods 10, the spoiler shaft 9 A spoiler bushing 11 is arranged on it, and a plurality of spoiler vanes 12 are arranged on the spoiler bushing 11 . By adopting the above-mentioned technical solution, the turbulence device can be arranged so that the mud can be turbulent and agitated during the transportation process, thereby further improving the accuracy of adding the solidifying agent powder.

[0021] The remaining features and advantages of this embodiment are the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com