Scraper conveyor

A technology of scraper conveyor and scraper chain, which is applied in the field of scraper conveyor, can solve the problems of poor adaptability of scraper conveyor, achieve the effect of expanding the use mode and improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

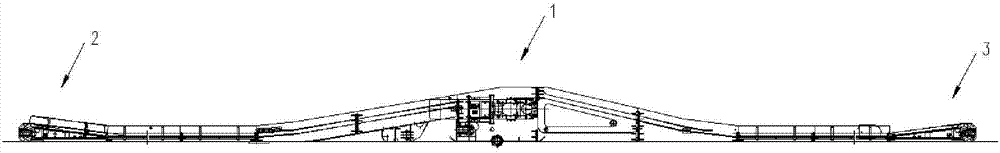

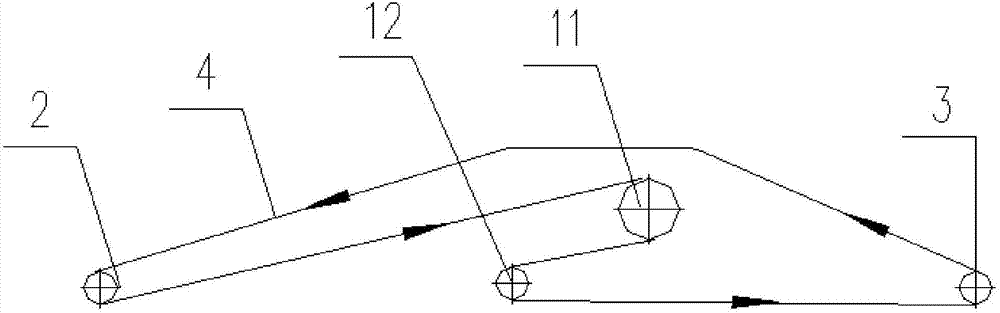

[0020] Such as figure 1 , figure 2 As shown, a scraper conveyor includes a driving mechanism 1, an unloading end 2, and a loading end 3; the driving mechanism 1 is located between the unloading end and the loading end.

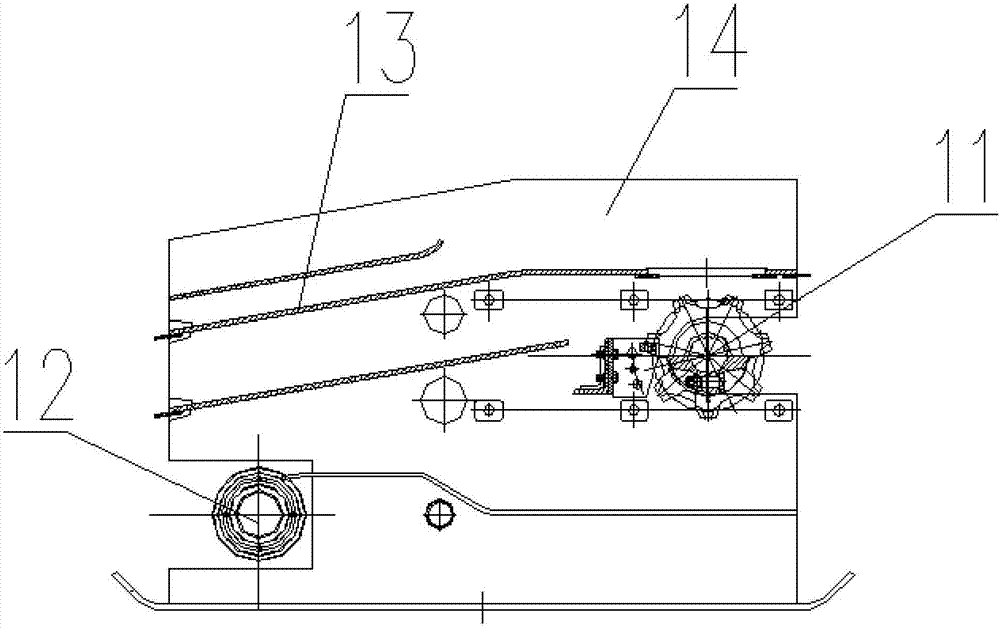

[0021] Wherein the driving mechanism 1 includes a sprocket 11, a transmission drum 12, and a supporting plate 13; the supporting plate 13 is above the sprocket 11, and the driving drum 12 is below the sprocket 11; the driving drum 12 is located between the sprocket 11 and the unloading end 2 or the loading end 3 between. In this embodiment, the driving drum 12 is located between the unloading end 2 of the sprocket 11 . The drive mechanism 1 includes a head frame; the head frame includes two side plates 15 , and the supporting plate 13 is fixed on the side plates 14 . The two ends of the rotating shaft of the transmission drum 12 are respectively fixed on the two side plates 14 of the machine head frame.

[0022] Scraper chain 4 is set to:

[0023] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com