Polyester board for high-speed railway luggage rack and preparation method of polyester board

A technology of polyester board and luggage rack, which is applied in the field of polyester board for high-speed rail luggage rack and its preparation, can solve the problems of poor waterproof performance of polyester board and low safety performance of luggage rack, and achieve good load-bearing effect, convenient use, The effect of good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0065] A polyester board for a high-speed rail luggage rack, comprising:

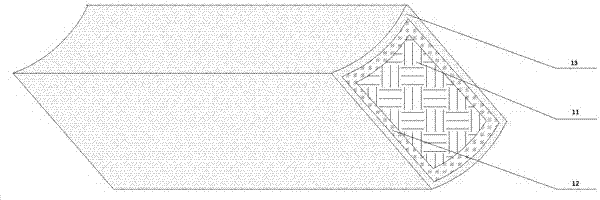

[0066] Polyester board body 1: polyester layer 11, adhesive layer 12 and frosted layer 13 from inside to outside;

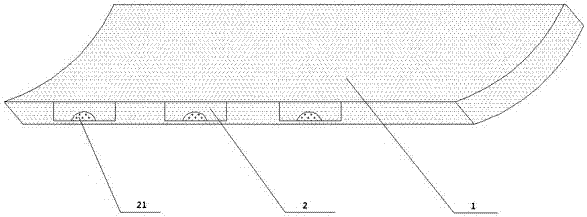

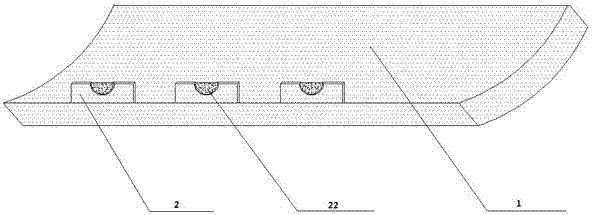

[0067] Folding plate 2: the folding plate 2 is connected with the polyester board body 1 through the turning shaft;

[0068] Groove I 12; and

[0069] Groove II 22: Groove II 11 and groove I 21 have the same shape and size, and both are located on opposite sides of the turning axis.

[0070] Specifically, the polyester layer 11 consists of the following components:

[0071] 90 parts by weight of polycarbonate;

[0072] PMMA 20-30 parts by weight;

[0073] Dispersant 1.0-1.5 parts by weight.

[0074] Specifically, the bonding layer 12 is composed of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com