Full-automatic pocket cake baking production line and production processing method

A fully automatic, production line technology, applied in baking, baking workshops, food ovens, etc., can solve the problems of increasing food uncontrollable factors and unsafety, and the difficulty of cooked food processing, so as to save labor costs and facilitate the layout , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

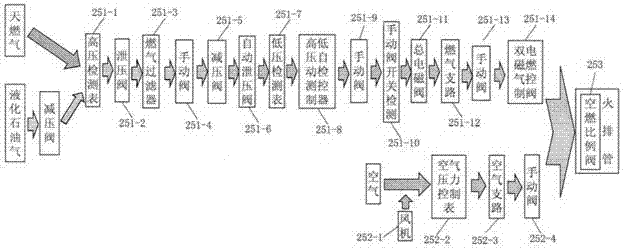

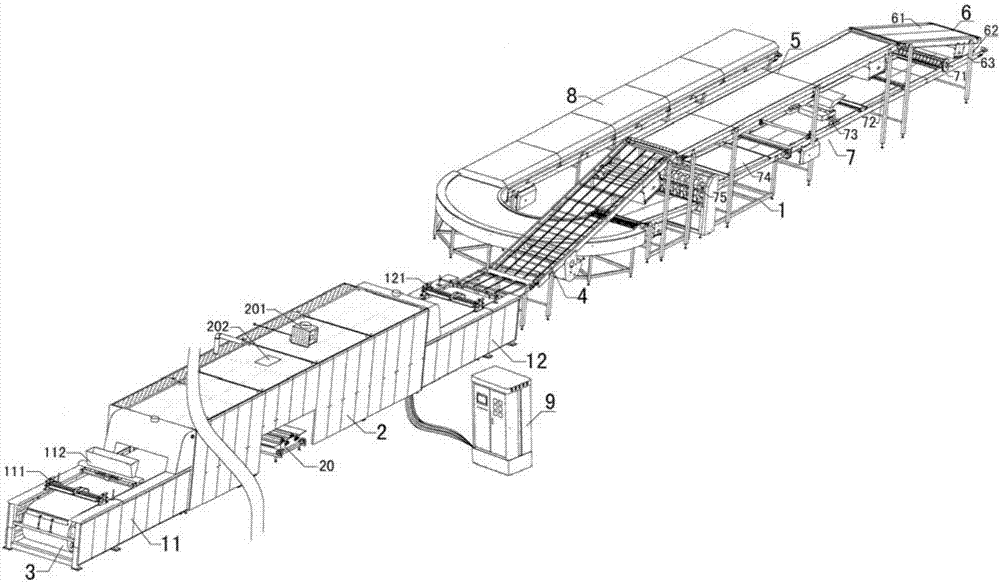

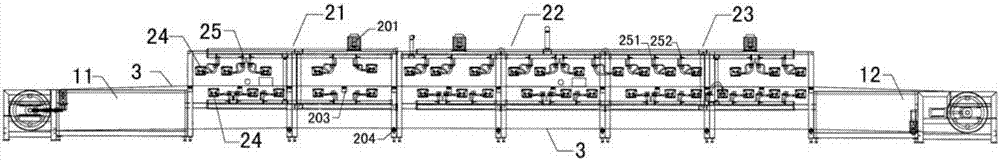

[0033] refer to Figure 1-7As shown, the fully automatic baked pocket cake production line includes an oven-in platform 11, an oven-out platform 12, a tunnel oven 2, a steel belt 3, a mesh chain conveyor belt 4, a cooling conveyor belt 5, a rolling mechanism 6, a sandwich forming mechanism 7, and a sterilization mechanism 8. Rack 1 and PLC control box 9; the furnace feeding platform 11 is provided with a seated adjusting bearing 113, a passive roller 114, a tensioning cylinder 115 and a furnace feeding correction adjustment rod 116, and the belt seated adjusting bearing 113 Connected with the tensioning cylinder 115, the passive roller 114 is set on the belt seat adjusting bearing one 113, and the furnace feed deviation correction adjustment rod 116 is set at the front end of the passive roller 114 to adjust the entering angle of the steel strip 3; the furnace exit platform 12 is set There are belt seat adjusting bearing 2 122, driving roller 123, adjusting screw rod 124, gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com