Anti-EMI (electro magnetic interference) microwave power distributor and manufacturing method thereof

An anti-electromagnetic interference and microwave power technology, applied in waveguide-type devices, circuits, electrical components, etc., can solve problems affecting the reliability of electronic systems, and achieve the effects of improving anti-interference, reducing volume, and suppressing space radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following description.

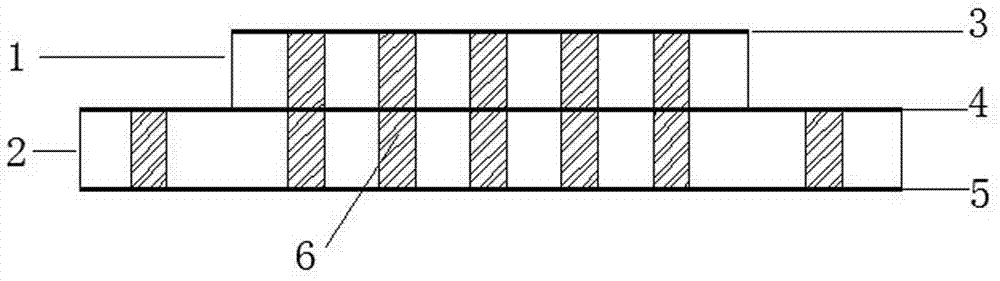

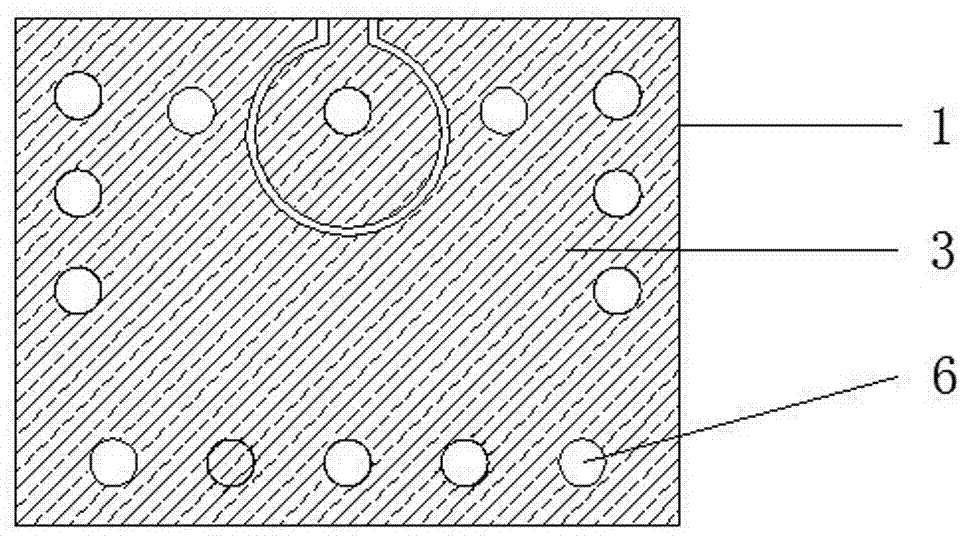

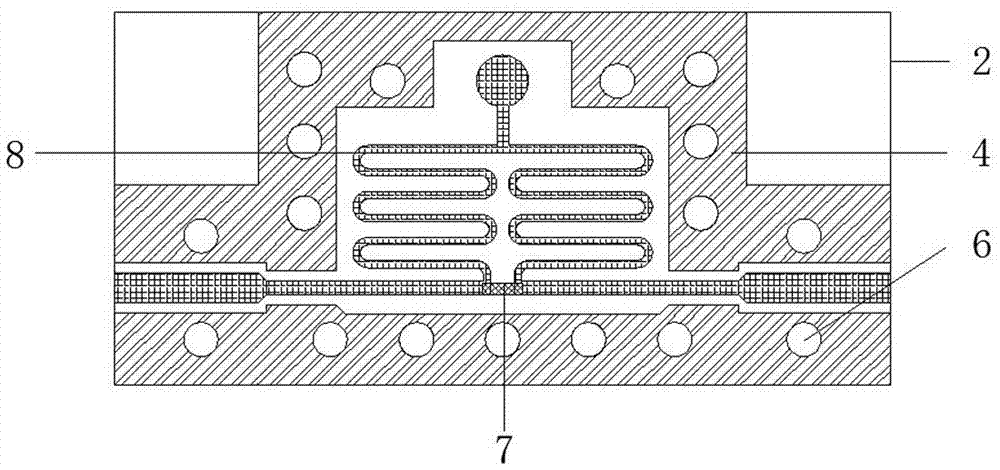

[0029] Such as figure 1 As shown, it is an overall cross-sectional view of the microwave power divider of the present invention, including a top silicon-based substrate 1, a bottom silicon-based substrate 2, a resistive film 7, a top metal layer 3, an intermediate metal layer 4 and a bottom metal layer 5; the top silicon-based substrate 1 and the underlying silicon-based substrate 2 are provided with through holes 6, the lower surface of the top-layer silicon-based substrate 1 and the upper surface of the underlying silicon-based substrate 2 are connected by gold-gold bonding, and the contact part of the top-layer silicon-based substrate 1 and the underlying silicon-based substrate 2 A strip-shaped microwave transmission line metal layer 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com