Full lift blade type vertical-axis wind turbine

A blade-type, vertical-axis technology, applied in the direction of wind turbines, wind turbines at right angles to the wind direction, wind turbine control, etc., can solve problems such as production difficulties, complex mechanisms for adjusting the angle of attack, and loss of cut-off surfaces, and achieve maintenance Low maintenance costs, improved wind energy utilization, and large swing freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

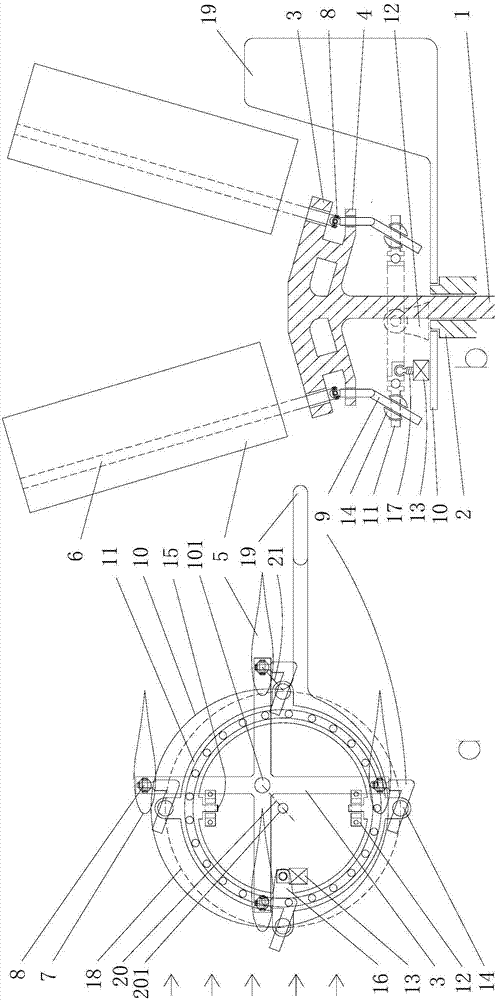

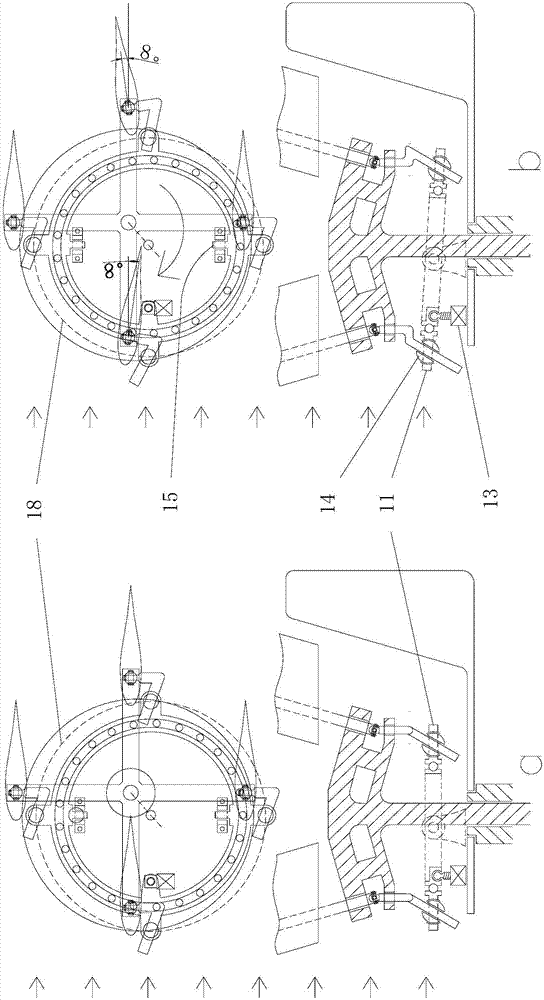

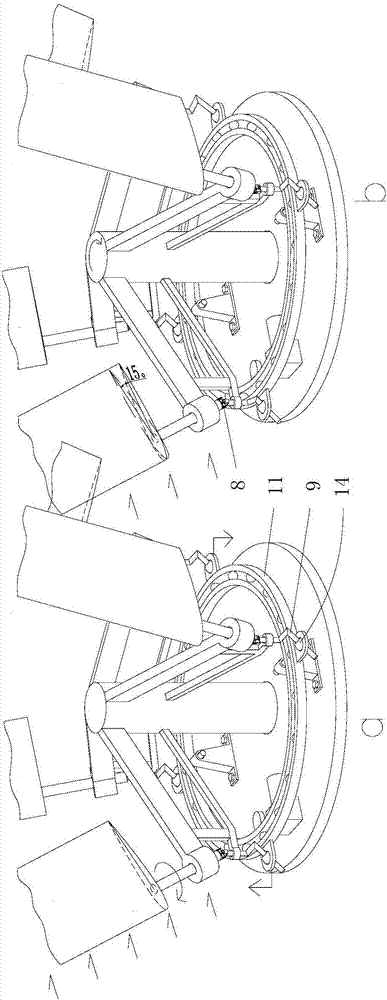

[0025] Such as Figure 1-Figure 3 Shown is a schematic view of an embodiment of the full-lift blade vertical axis wind turbine of the present invention. In this embodiment, the wind turbine has four sets of blades. The wind turbine includes three parts: blades and a support frame, a device for adjusting the angle of attack, and a wind-directing device.

[0026] Such as figure 1 As shown, the power take-off shaft 1 is inserted into the frame bushing 2 to rotate independently, and the upper end of the power take-off shaft 1 is rigidly connected to the upper support frame 3 and the lower support frame 4; Rotationally connected in the shaft hole at the outer end of the upper support frame 3; the top of the blade 5 can also be provided with reinforcements to increase the strength of the blade. The larger opening on the upper part of the blade can enhance the utilization rate of wind energy; the lower part of the blade, close to the rotating shaft, is beneficial to install an adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com