Ash removing device for soot pipeline and work method of ash removing device for soot pipeline

An ash cleaning device and soot technology are applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., which can solve the problems of difficult removal, flue ash accumulation, ash scaling, etc., and achieve good ash cleaning effect. The effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

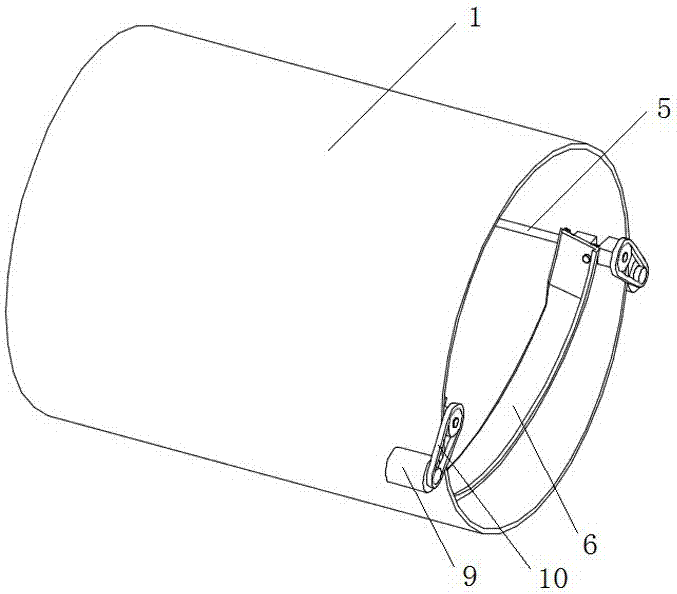

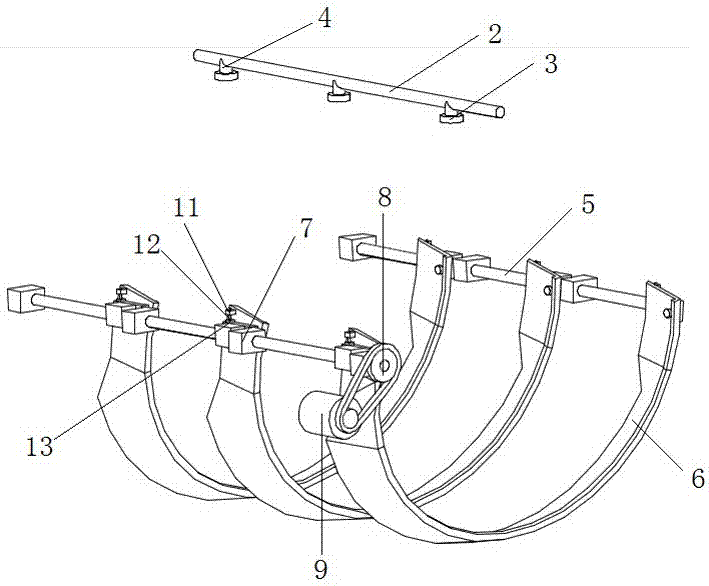

[0013] Such as Figure 1~2 As shown, a soot pipe cleaning device includes a water pipe 2 arranged in the axial direction on the inner top of the soot pipe 1. The water pipe 2 is provided with nozzles 3 spraying toward the inner wall of the soot pipe at intervals. The nozzle is provided with a control valve 3. The nozzle The spraying angles are not the same. There are screw rods 5 arranged in the axial direction on both sides of the soot pipe 1, and a plurality of ash shovel plates 6 arranged at intervals are connected between the screw rods 5 on both sides. The ash shovel plates 6 are arc Shaped structure and its lower side is attached to the inner side wall of the lower part of the soot pipe 1; the two ends of the ash shoveling plate 6 are hinged on the nut seat 7 threaded with the screw rod 5 so that when the screw rod rotates, the ash shoveling board is driven to move in the axial direction. When cleaning is required, spray water with chemical reagents onto the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com