A kind of pulping control method

A control method and pulping technology, which can be applied to kitchen utensils, household utensils, applications, etc., and can solve problems such as poor crushing, empty beating, and overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

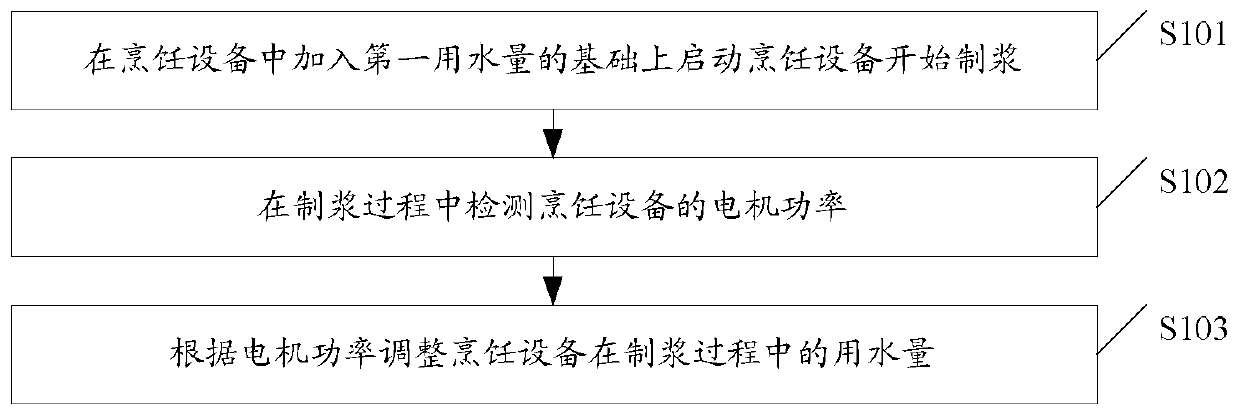

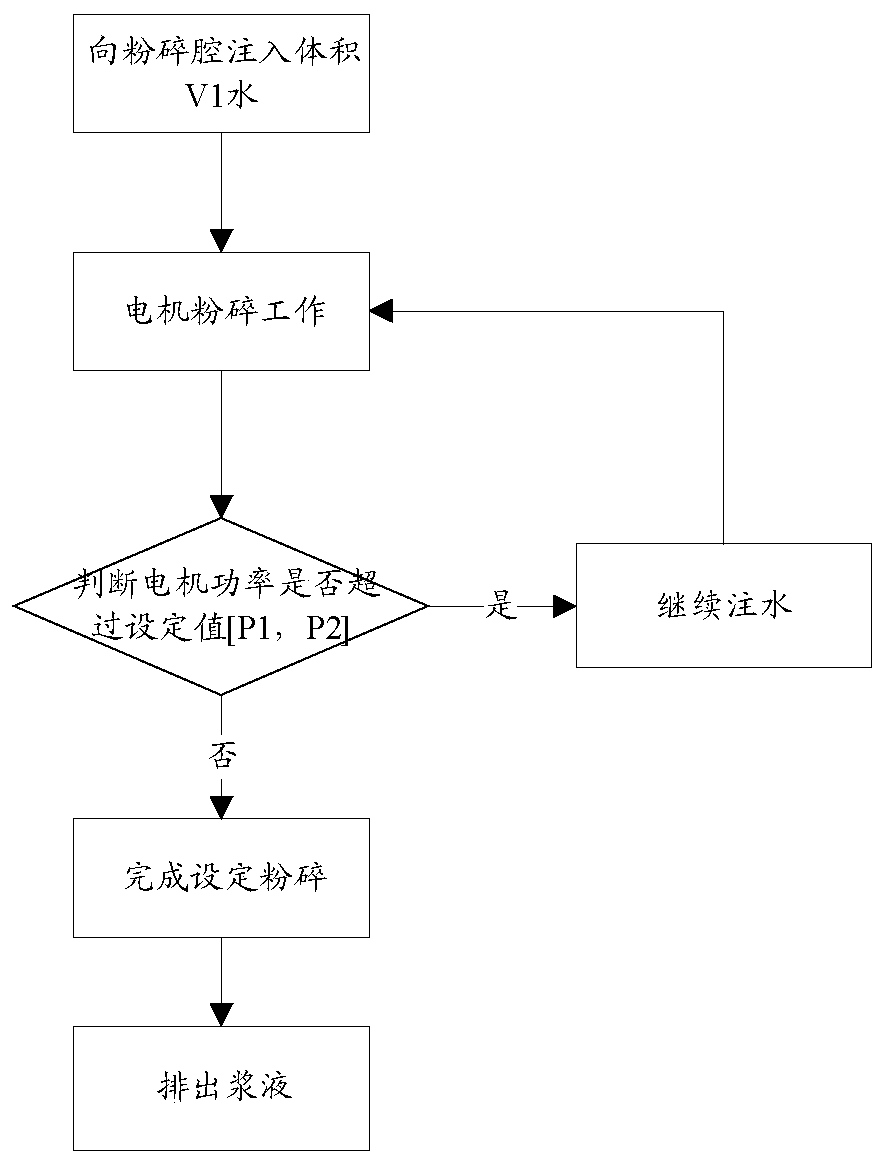

[0045] A pulping control method such as figure 1 , figure 2 As shown, the method includes S101-S103:

[0046] S101. Start the cooking device on the basis of adding the first amount of water into the cooking device to start pulping.

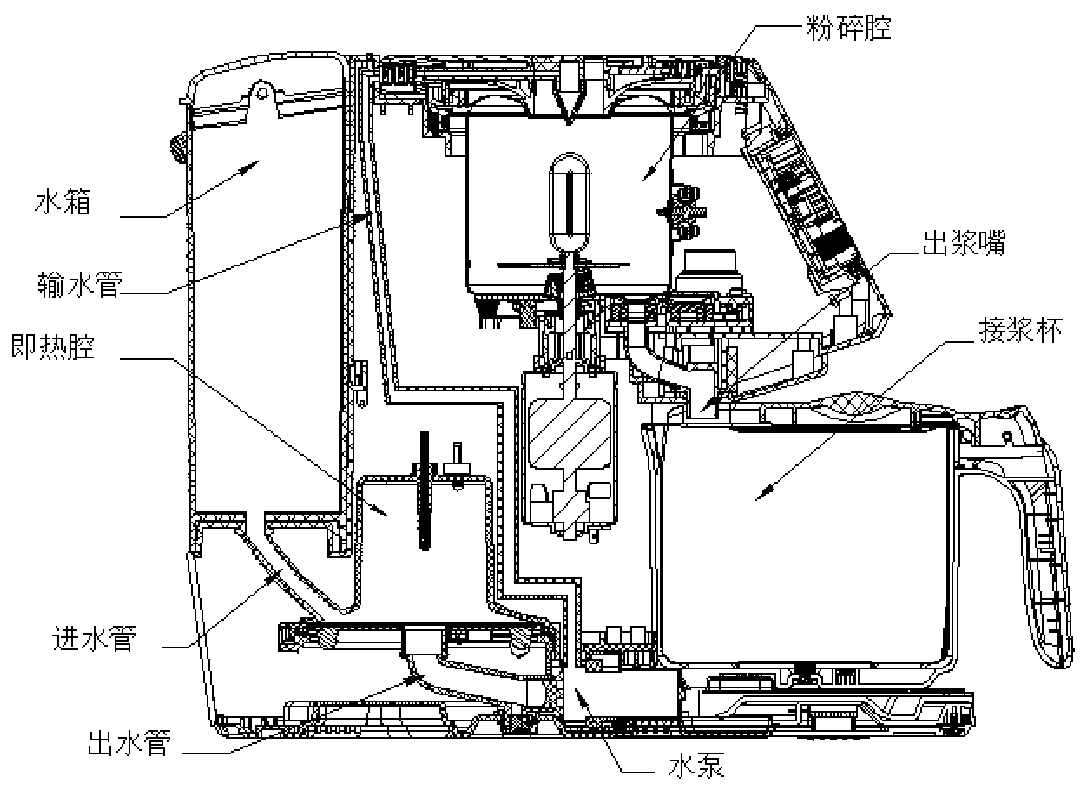

[0047] In the embodiment of the present invention, the cooking equipment can be a soybean milk machine, and the schematic diagram of its structural embodiment can be as follows image 3 As shown, the soymilk machine may include: a crushing chamber, a water tank, an instant heating chamber, a water pump, a pulp outlet nozzle, a pulp receiving cup, a water inlet pipe connecting the water tank and the instant heating chamber, an outlet connecting the instant heating chamber and the water pump water pipe and the water delivery pipe connecting the pulverizing chamber and the water pump, the instant hot chamber can heat the water delivered by the water tank, the water pump draws the water in the instant hot chamber through the water outlet pipe, and ...

Embodiment 2

[0069] The second embodiment is a specific embodiment of the rated material amount Me and the rated power Pe of the motor in the first embodiment, and the correspondingly calculated specific embodiments of the lower limit of the material amount M1, the first water amount V1 and the power range.

[0070] Optionally, the rated material amount Me may include: 50-200g; the rated power Pe may include: 150-300W.

[0071] Optionally, rated material amount Me=80g; rated power Pe=180W.

[0072] In the embodiment of the present invention, if the specification stipulates that the rated amount of dry beans is 80g, and the motor power under rated load conditions, that is, the rated power is 180W, then the lower limit of the amount of material M1=60g can be determined according to the above-mentioned relational formula. The water consumption V1 is 240g, P1 is set to 216W, and P2 is set to 144W, which can meet the design requirements.

[0073] In the embodiment of the present invention, the...

Embodiment 3

[0075] Such as Figure 4 As shown, Embodiment 3 increases the motor speed adjustment on the basis of Embodiment 1 (the motor power is adjusted accordingly), which is a compensation for the scheme of Embodiment 1. When the water consumption regulation is limited, the motor speed can be adjusted to achieve The purpose of motor power falling within the preset power range.

[0076] Optionally, the method further includes: adjusting the motor speed of the cooking device according to the current motor power and water consumption.

[0077] In the embodiment of the present invention, when the amount of material put in by the user exceeds a certain range, a large amount of water needs to be added to achieve a suitable concentration, but limited by the volume of the crushing cup, when the slurry capacity reaches a certain proportion of the total capacity of the crushing chamber, It is no longer possible to adjust the concentration of the slurry by injecting water to achieve a suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com