Spectroscopic device detection system and detection method

A spectroscopic device and detection system technology, which is applied in the detection field, can solve problems such as complex operation, non-compliance with factory requirements, and influence on detection results, and achieve the effects of eliminating the influence of detection results, reliable detection results, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

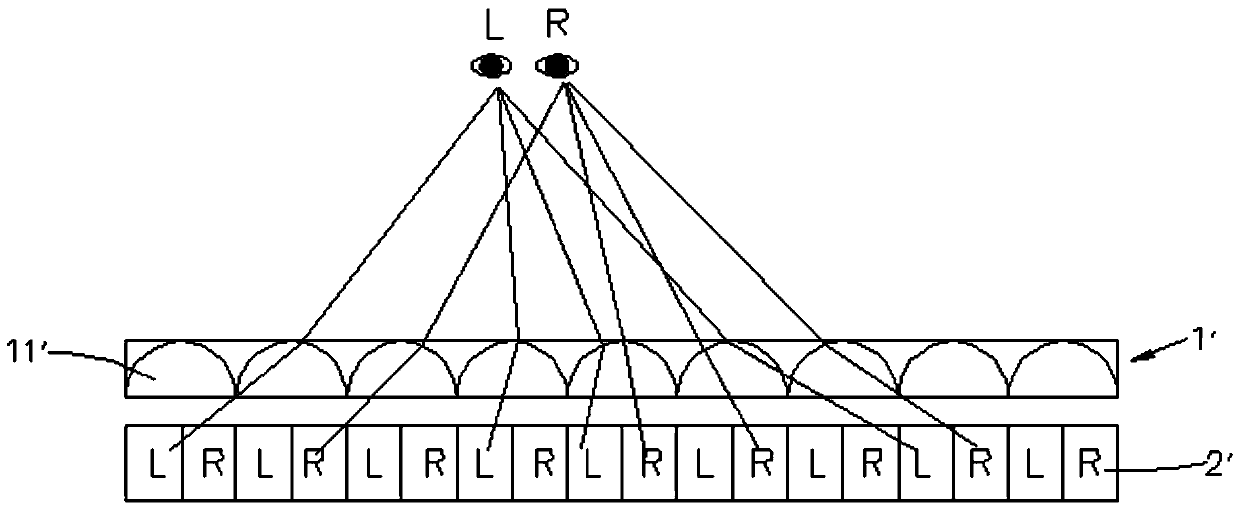

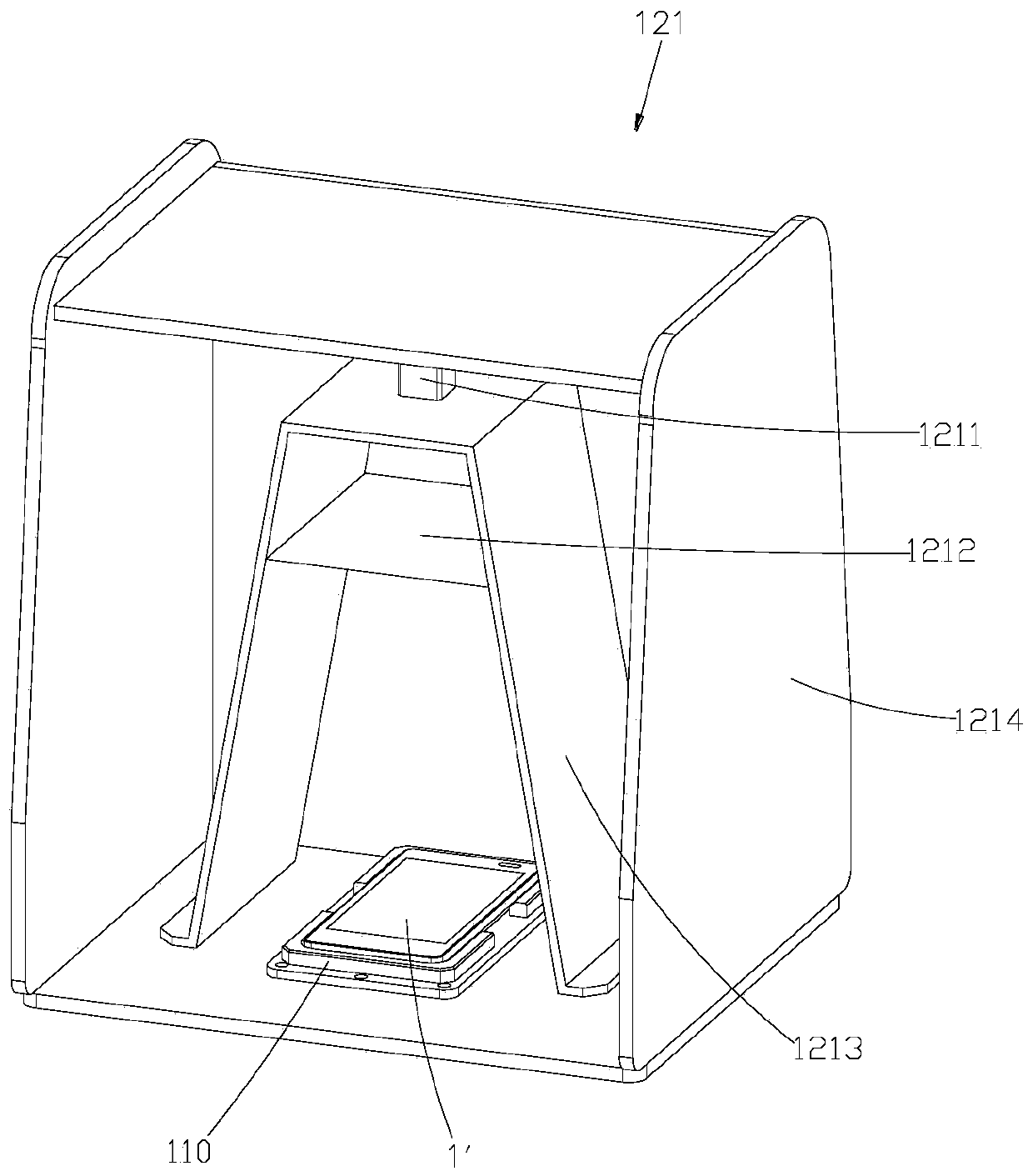

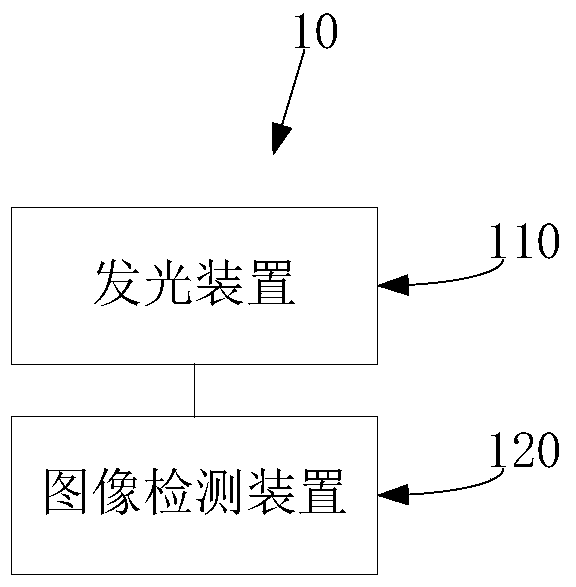

[0058] Such as Figure 1 to Figure 3 As shown, the spectroscopic device detection system 10 provided by the embodiment of the present invention is used to detect whether there is a broken line in the spectroscopic device 1'. The spectroscopic device detection system 10 includes a light emitting device 110 and an image detection device 120. During detection, the light-emitting device 110 provides a light source, and the light-emitting device 110 irradiates light on the spectroscopic device 1'. Since the spectroscopic device 1' has a light-splitting effect, the light emitted by the light-emitting device 110 passes through the spectroscopic device 1' to go out, and the image detection device 120 The light emitted by the spectroscopic device 1' is collected to form a detection image, and the image detection device 120 performs image processing on the detection image to determine whether there is a broken line area in the spectroscopic device 1'. Compared with the existing technolo...

Embodiment 2

[0077] Such as figure 2 and Figure 6 As shown, the structure of the spectroscopic device detection system provided in this embodiment is substantially the same as that of the spectroscopic device detection system 10 provided in Embodiment 1. The difference is that the image processing component 122 also includes an area comparison module 128, and the area comparison module 128 stores If there is a detection template, the area comparison module 128 performs image comparison processing on the detection template and the detection image, and outputs the comparison result. The detection template can be set to have no display image. Through image comparison processing, if the comparison result is that the detection image is different from the detection template, that is, the detection image contains display content, there is a broken line area in the spectroscopic device 1'. If the comparison result is The detection image is the same as the detection template, that is, the detect...

Embodiment 3

[0080] Such as figure 1 , figure 2 and Figure 7 As shown, another object of the embodiment of the present invention is to provide a detection method for a spectroscopic device, which is used to detect whether there is a broken line area in the spectroscopic device 1'. The detection method for the spectroscopic device 1' includes:

[0081] S1 irradiates the light on the light splitting device 1';

[0082] S2 collects the light emitted by the spectroscopic device 1' to form a detection image;

[0083] S3 judges whether there is a disconnection area in the spectroscopic device 1 ′ according to the detected image.

[0084] Since the spectroscopic device 1' has the function of splitting light, the light irradiated on the spectroscopic device 1' goes out, and the light emitted by the spectroscopic device 1' is collected to form a detection image, and it is determined whether there is a broken line in the spectroscopic device 1' based on the detection image. Compared with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com