Stereoscopic display device detection system and detection method thereof

A technology for a stereoscopic display device and a detection system, which is applied to stereoscopic systems, televisions, electrical components, etc., can solve the problems of complex operation, crosstalk, low test efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

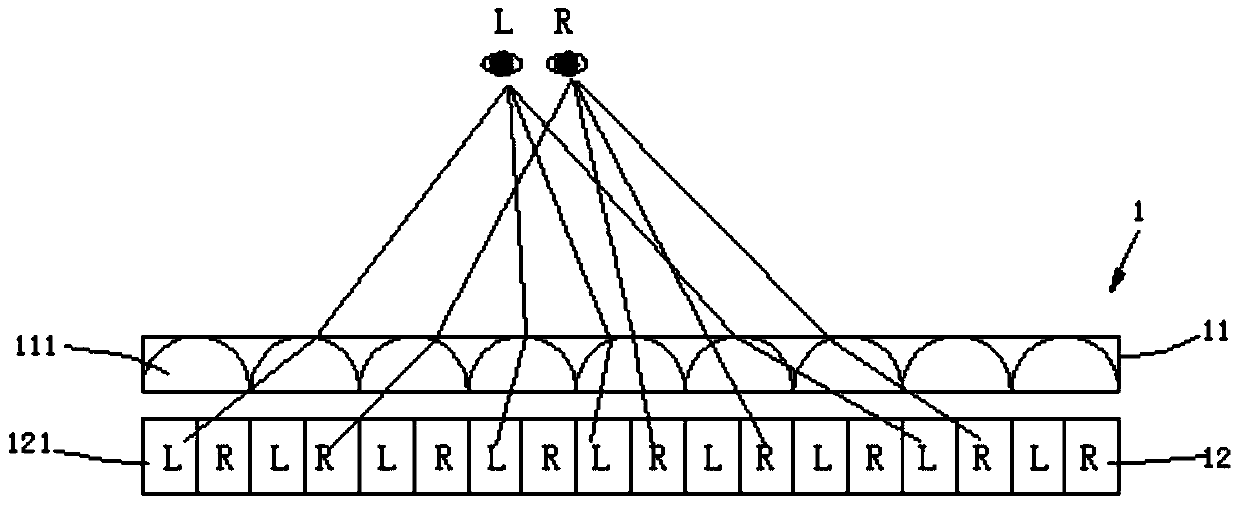

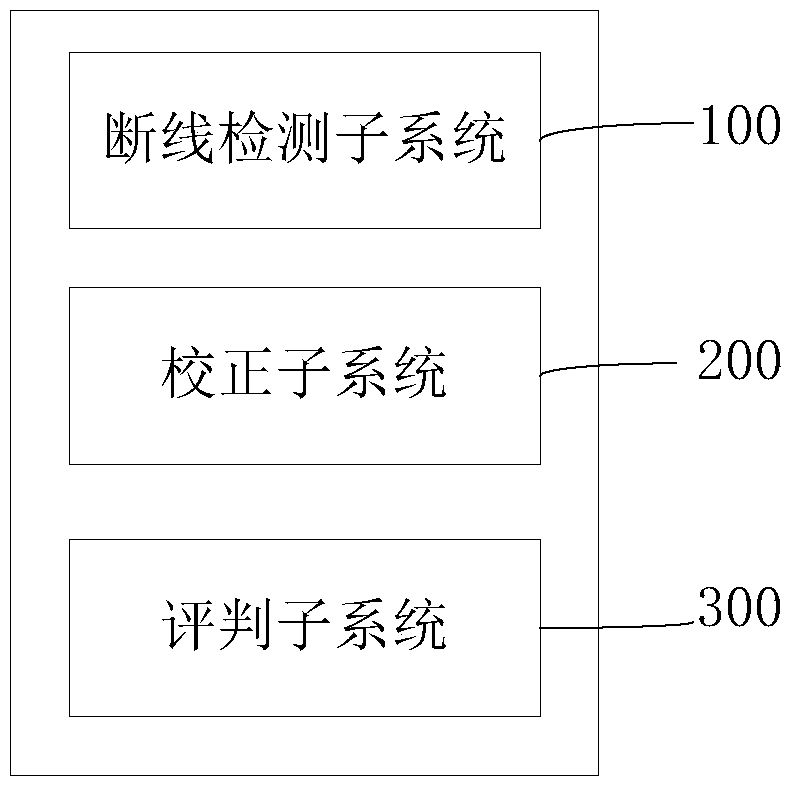

[0085] Such as figure 1 and figure 2 As shown, the detection system (not shown in the figure) provided by the embodiment of the present invention is used to detect the stereoscopic display device 1. The detection system includes a disconnection detection subsystem 100 and a calibration subsystem 200. The disconnection detection subsystem 100 The disconnection detection is performed on the stereoscopic display device 1 , and the calibration subsystem 200 obtains calibration parameters satisfying preset conditions of the stereoscopic display device 1 , and the calibration parameters are used to correct assembly errors of the stereoscopic display device 1 . The three-dimensional display device 1 includes a light-splitting device 11 and a display panel 12. If the light-splitting device 11 has a disconnection defect and is not detected, it is directly installed on the display panel 12, which will directly affect the display effect of the three-dimensional display device 1. When th...

Embodiment approach 2

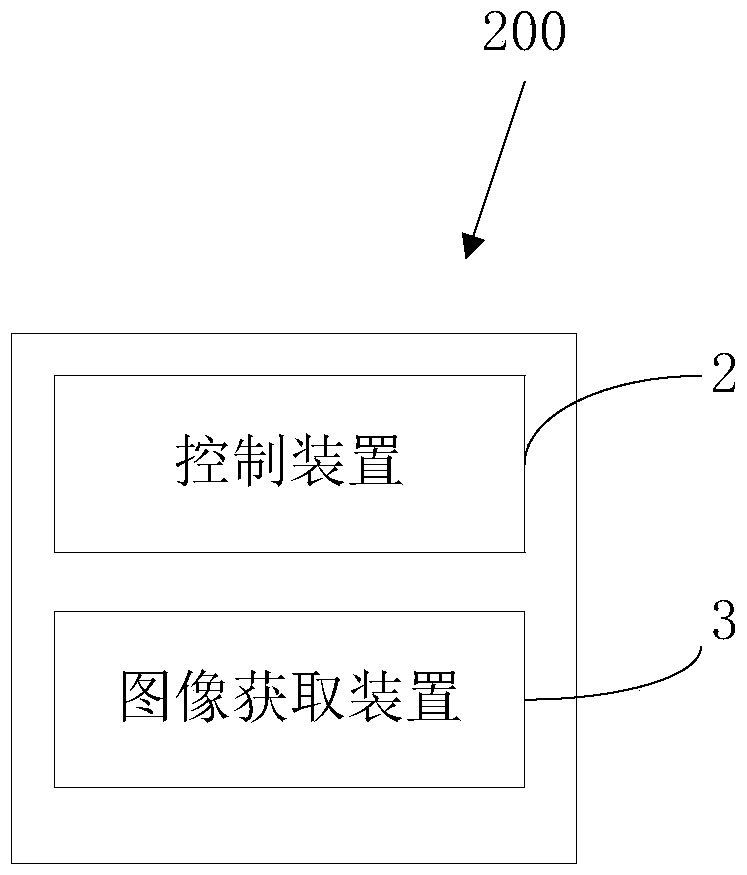

[0122] The stereoscopic display device detection system provided in this embodiment has the same structure as the stereoscopic display device detection system provided in Embodiment 1, the difference is that, as figure 1 , image 3 and Figure 4 As shown, the stereoscopic display device 1 is provided with a tracking unit (not shown in the figure), and the mounting part 31 is provided with a feature mark 33 that can be recognized by the tracking unit. The tracking unit provided in this embodiment may be an infrared detection device, a tracking camera or other devices. When the tracking unit tracks the signature 33, the control device 2 controls the image acquisition device 3 to acquire a stereoscopic image. The feature identifier 33 provided in this embodiment may be a flat cardboard or a three-dimensional head portrait with features that can be recognized by the tracking unit, and details will not be repeated here. The tracking function of the tracking unit is turned on, an...

Embodiment approach 3

[0131] Such as figure 1 and Figure 10 As shown, this embodiment provides a calibration method for a stereoscopic display device, which is used to obtain a calibration parameter for a stereoscopic display device 1 that satisfies preset conditions, including the following steps:

[0132] S1, detecting whether the stereoscopic display device 1 is disconnected;

[0133] S2. If the stereoscopic display device 1 is not disconnected, acquire a correction parameter satisfying a preset condition of the stereoscopic display device 1 , and the correction parameter is used to correct an assembly error of the stereoscopic display device 1 .

[0134] The calibration parameters in this embodiment are obtained by detecting the assembled stereoscopic display device 1 to obtain the parameters corresponding to the assembly error. A stereoscopic image displayed by the stereoscopic display device 1 is acquired, and a correction parameter satisfying a preset condition is obtained according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com