Radish peeling forming machine

A molding machine and radish technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of time-consuming and large human resources, and achieve the effect of reducing labor, improving efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

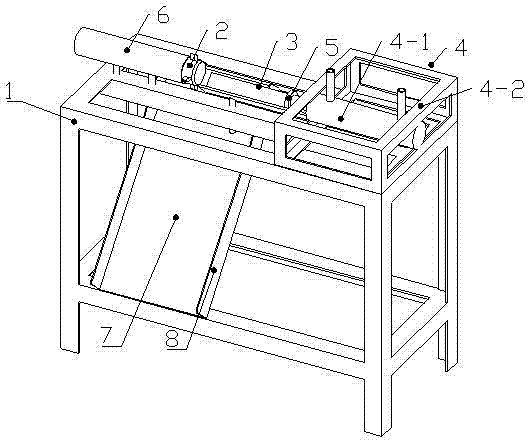

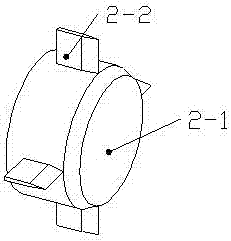

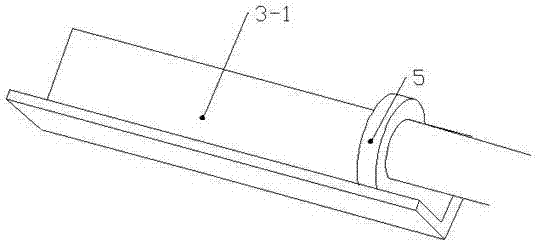

[0015] Such as Figure 1-3 As shown, a radish peeling and forming machine includes a frame 1, wherein the frame 1 is provided with a peeling device 2, a feeding device 3, and a power device 4 in sequence from front to back. The device 3 is provided with a push plate 5 slidably, and the output end of the power device 4 is connected with the push plate 5 to push the push plate 5 to move in the direction of the peeling device 2. The peeling device 2 includes a ring that can peel and shape the radish. The shaped knife 2-1 and the flat blade 2-2 integrally formed on the outer ring of the ring knife 2-1, so that the ring knife 2-1 peels and shapes the radish, and the cut ring skin is cut by the flat blade 2-2 To make it fall, the outer ring of the knife edge of the annular knife 2-1 and the flat blade 2-2 are obliquely cut, thereby reducing the pressure between the knife edge of the annular knife 2-1 and the radish, facilitating rapid cutting and forming. The cut is flat. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com