Automatic chain detector

A detection machine and detection mechanism technology, applied in the direction of machine gear/transmission mechanism testing, measuring devices, testing of mechanical components, etc., can solve the problems of unreasonable structural design, slow manual speed, low detection accuracy, etc., and achieve its own ingenious structure Novelty, reasonable detection sequence and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

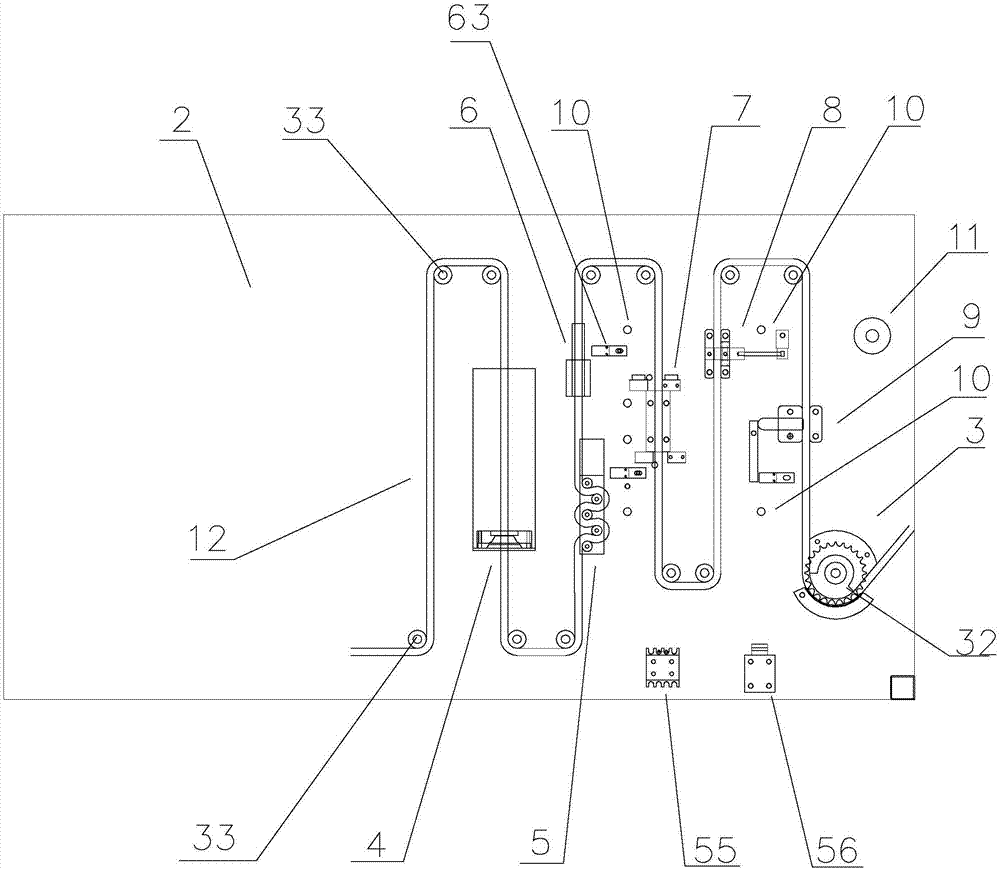

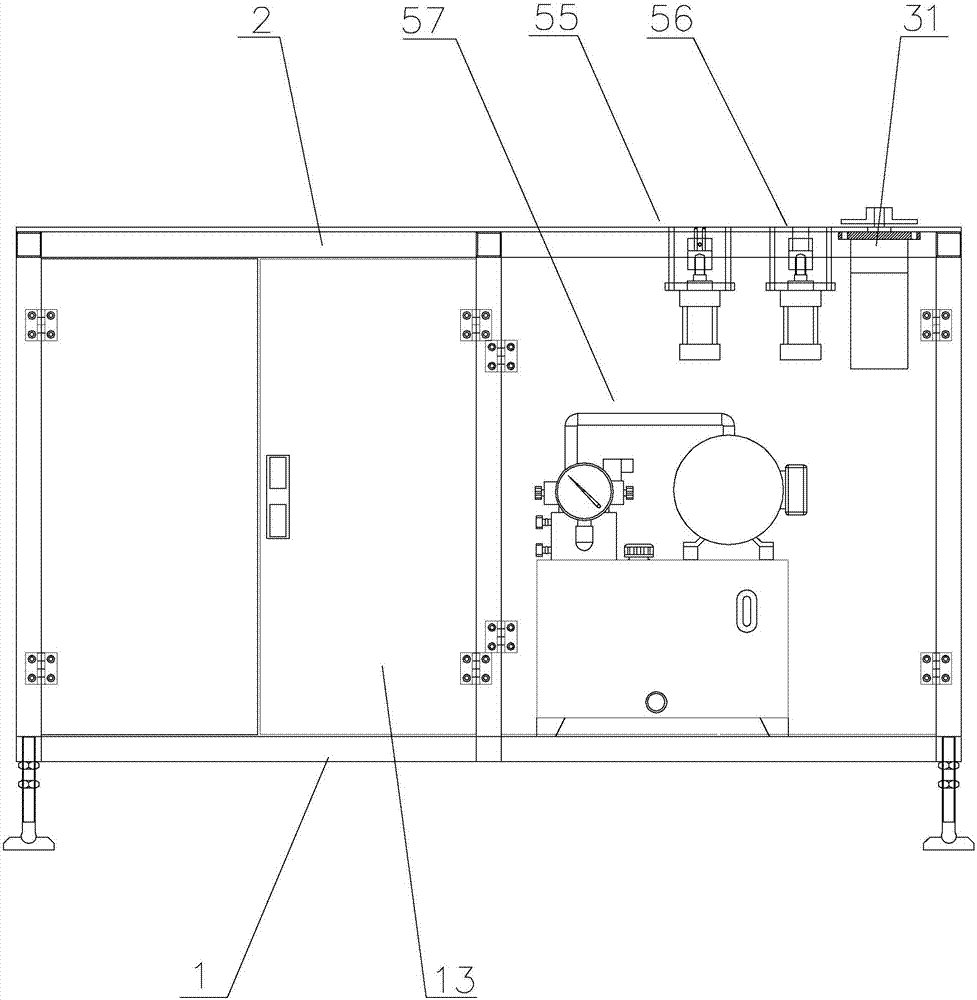

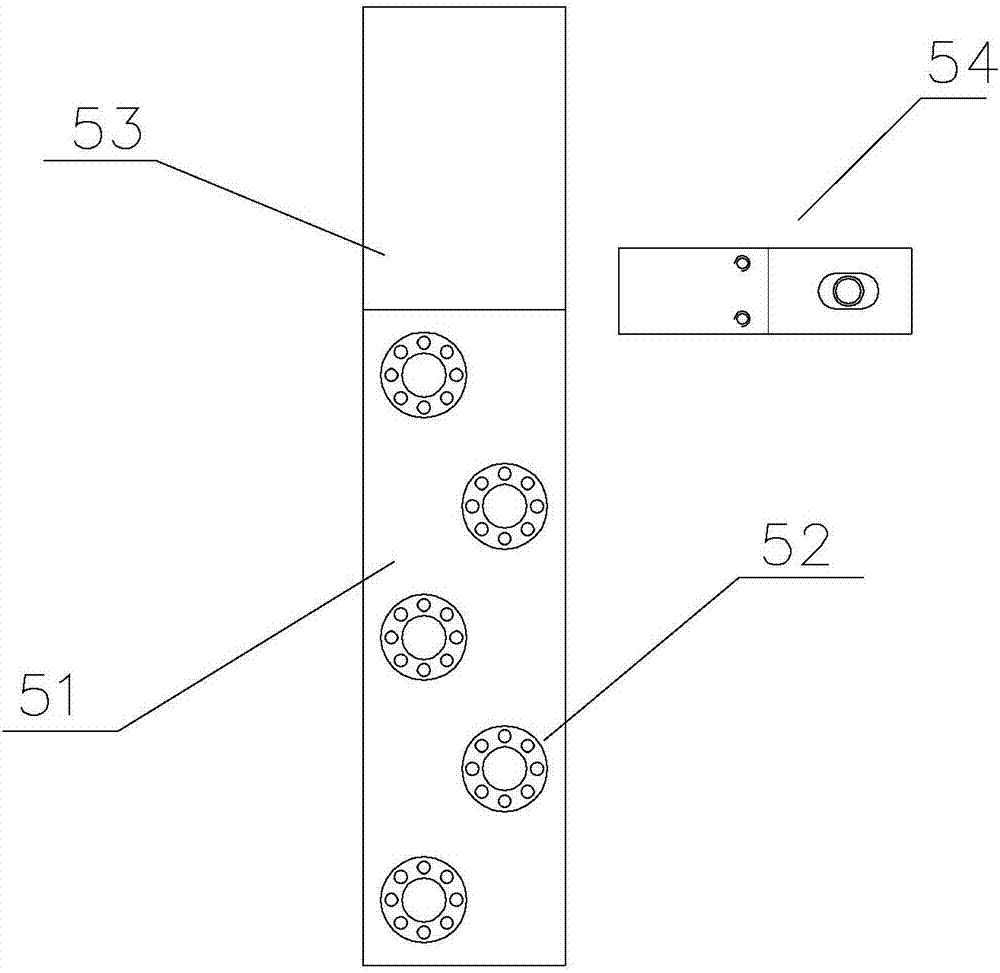

[0041] Such as figure 1 , figure 2 Shown, a kind of chain automatic detection machine, comprises whole frame 1, is located at the control electrical box 13 on described whole frame, is located at the panel 2 of whole frame top, chain driving mechanism 3 and is located at described panel The chain cleaning mechanism 4, the tight joint detection mechanism 5, the eccentric piece detection mechanism 6, the missing piece detection mechanism 7, the short pin detection mechanism 8 and the large and small tube detection mechanism 9 are arranged sequentially on the top and in the detection order.

[0042] Such as figure 1 , figure 2 As shown, the chain drive mechanism includes a transmission speed-regulating motor 31, a transmission sprocket 32 and 11 guide wheels 33; the transmission speed-regulating motor is arranged at the bottom of the panel, and the transmission sprocket is arranged on the panel and The speed-regulating motor is driven and connected, and the guide wheels ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com