Matching single-shaft double-floating brake for heavy-duty truck

A truck, double-floating technology, applied in the direction of mechanically driven drum brakes, brake parts, etc., can solve the problems of poor rotation of rollers, brake sticking, non-returning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

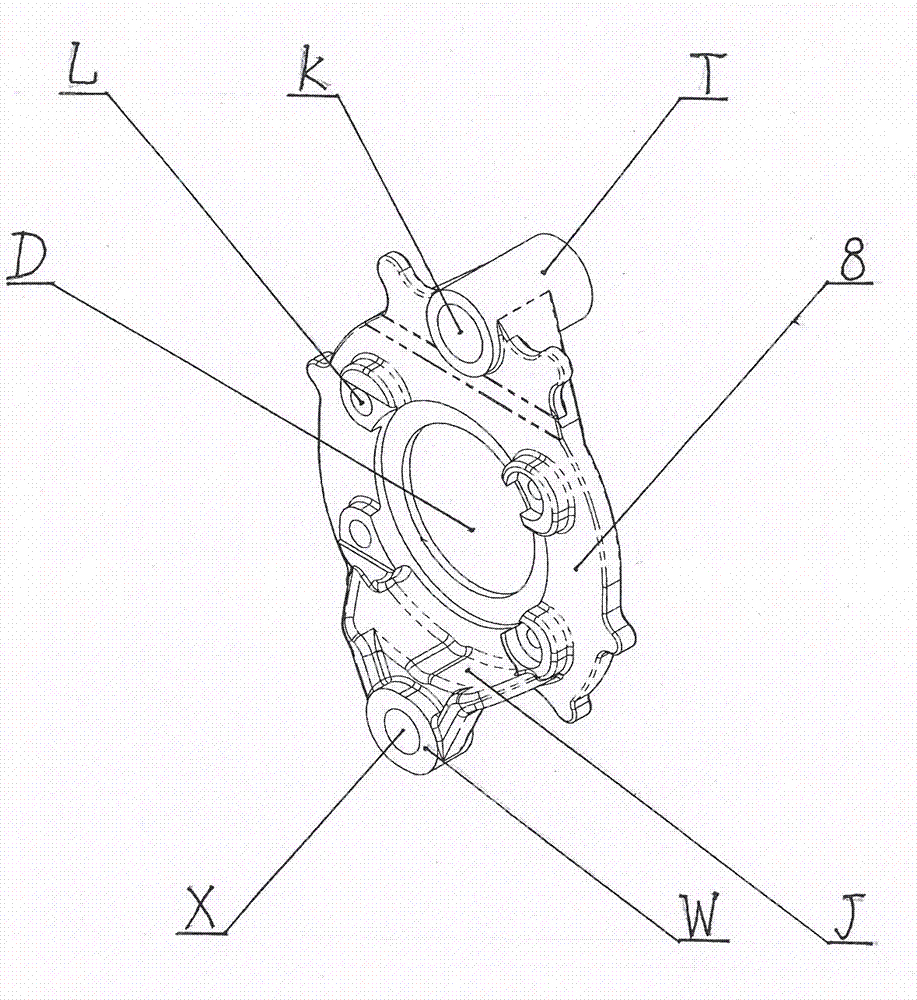

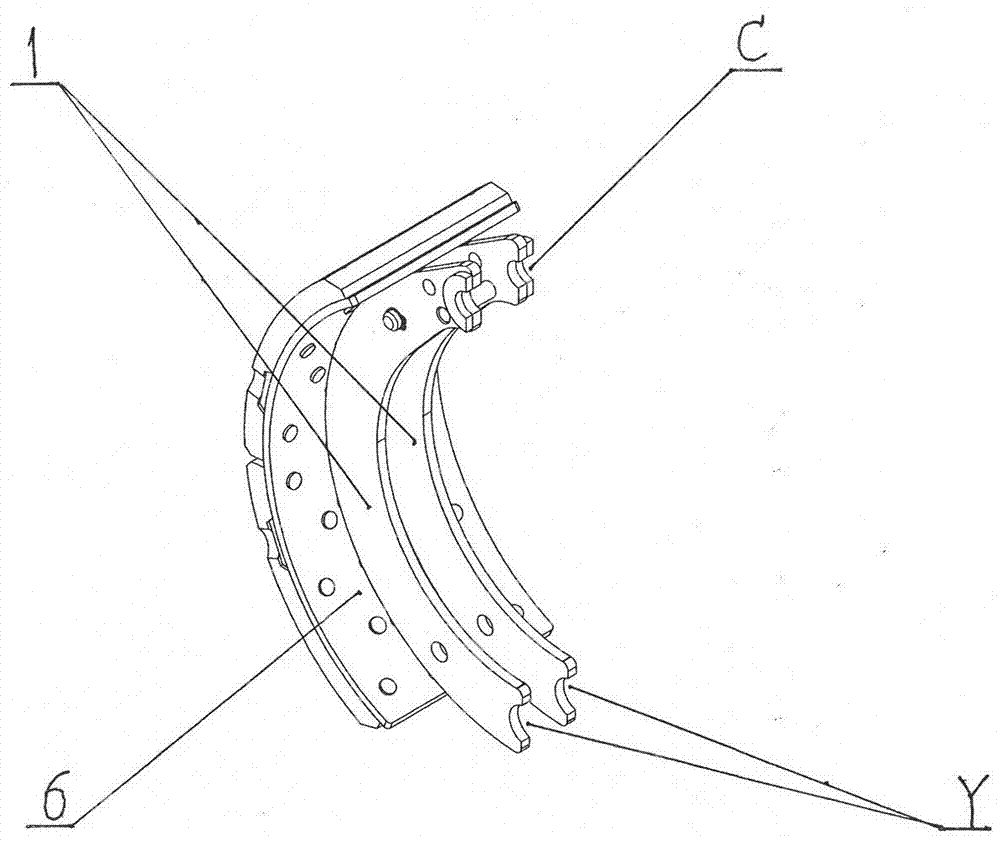

[0014] refer to figure 1 , the present invention comprises lower brake shoe 1, return spring 2, roller 3, camshaft 4, adjustment arm 5, upper brake shoe 6, brake bottom plate 8, brake shoe pin sleeve W at the lower end of brake bottom plate 8 A one-layer pin sleeve structure is adopted, the brake shoe pin sleeve W is connected to the surface of the brake bottom plate 2 through the reinforcement rib J, the brake shoe pin sleeve W is equipped with the brake shoe pin shaft 9, and the lower brake shoe 1 The brake shoe pin shaft bushing connected to the lower end of the brake shoe adopts the pin shaft semicircle groove Y structure, and the pin shaft semicircle groove Y of the lower brake shoe 1 on the left and right sides are relatively combined into a full circle snap ring, and the brake shoe pin The protruding part of the brake shoe pin shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com