Device and method for conveying pastes by utilizing high pressure air

A technology of high-pressure air and conveying equipment, which is applied in the direction of safety devices, earthwork drilling and filling, and can solve the problems of restricting the popularization and application of paste filling mining technology, leaving a large amount of filling paste, and underground environmental pollution, etc., to achieve filling The process is simplified, the device is easy to operate, and the effect of solving the complex cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

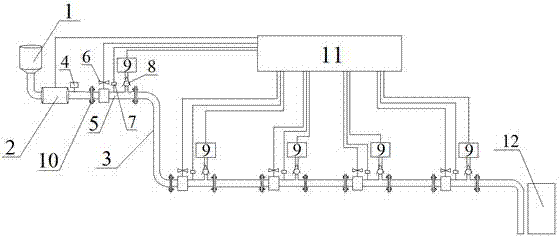

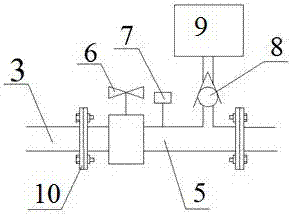

[0033] Such as Figure 1~2 As shown, a device utilizing high-pressure air to convey paste includes a slurry funnel 1, a filling pump 2, a high-pressure air conveying device, a flow meter 4, and a PLC controller 11;

[0034] The slurry funnel 1 is connected to the filling pipeline 3, a filling pump 2 is provided under the slurry funnel 1, and a flow meter 4 is arranged on the outlet direction pipeline of the filling pump 2, and the outlet end of the filling pump 2 is connected to a high-pressure air delivery device ; One or more high-pressure air delivery devices are provided on the filling pipeline 3; the number of the high-pressure air delivery devices is determined by the delivery capacity of a single high-pressure air delivery device and the length of the filling pipeline.

[0035] The high-pressure air delivery device includes a T-shaped three-way pipe 5, an electro-hydraulic stop valve 6, a concentration meter 7, a one-way valve 8, and a high-pressure air pump 9. The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com