Water-based flame-retardant paint and preparation method and application thereof

A fire-retardant coating, water-based technology, applied in the field of coatings, can solve the problems of poor compatibility of organic components, poor flame-retardant effect of flame retardants, and lower environmental protection of water-based coatings, and achieve good compatibility and good flame-retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

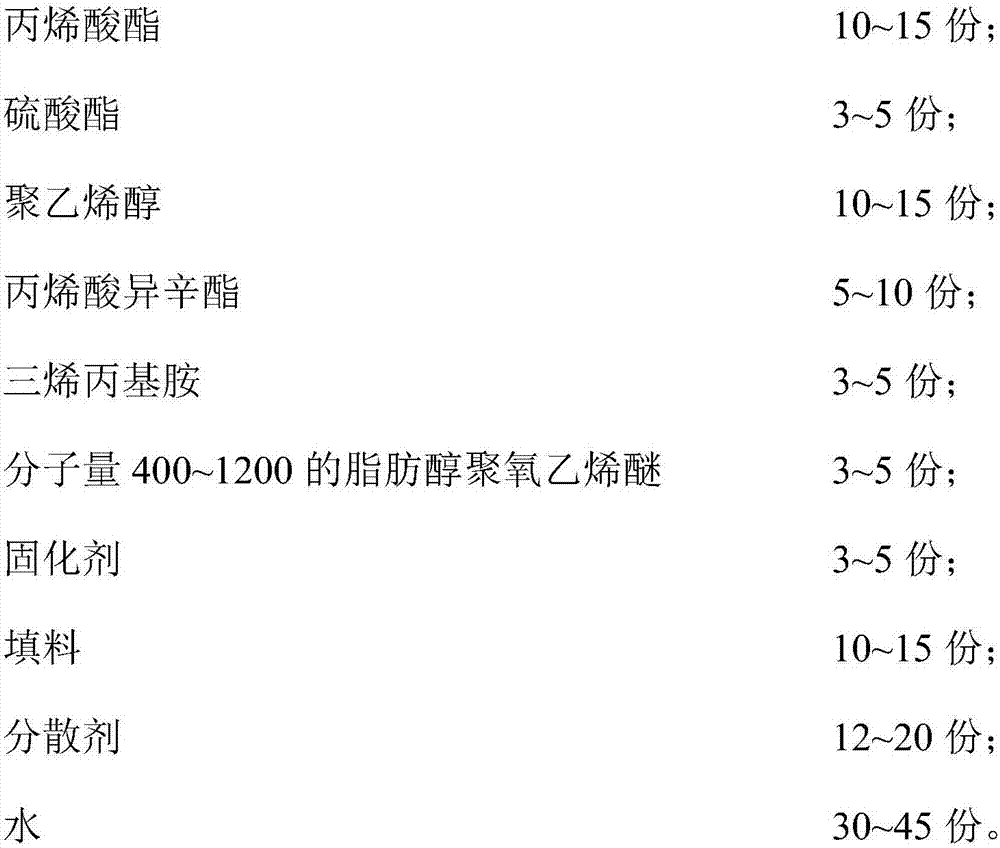

[0031] This embodiment provides a water-based flame-retardant coating and a preparation method thereof, and the water-based flame-retardant coating includes the following components in parts by weight:

[0032]

[0033]

[0034] Wherein, the relative molecular weight of the polyvinyl alcohol is 1700-2000; the curing agent is a blocked water-dispersible polyacetate and melamine, and its weight ratio is 1.5:4; the filler is titanium dioxide; the The dispersant described above is a silicone compound.

[0035] The preparation method of described waterborne flame retardant coating is:

[0036] (1) Add water, acrylate and polyvinyl alcohol into the reaction vessel in turn under stirring conditions at a stirring rate of 1100r / min according to the amount of raw material formula, and then add isooctyl acrylate, triallylamine and molecular weight 400 ~1200 fatty alcohol polyoxyethylene ether, disperse for 13 minutes;

[0037] (2) Step (1) After stirring, add curing agent, filler...

Embodiment 2

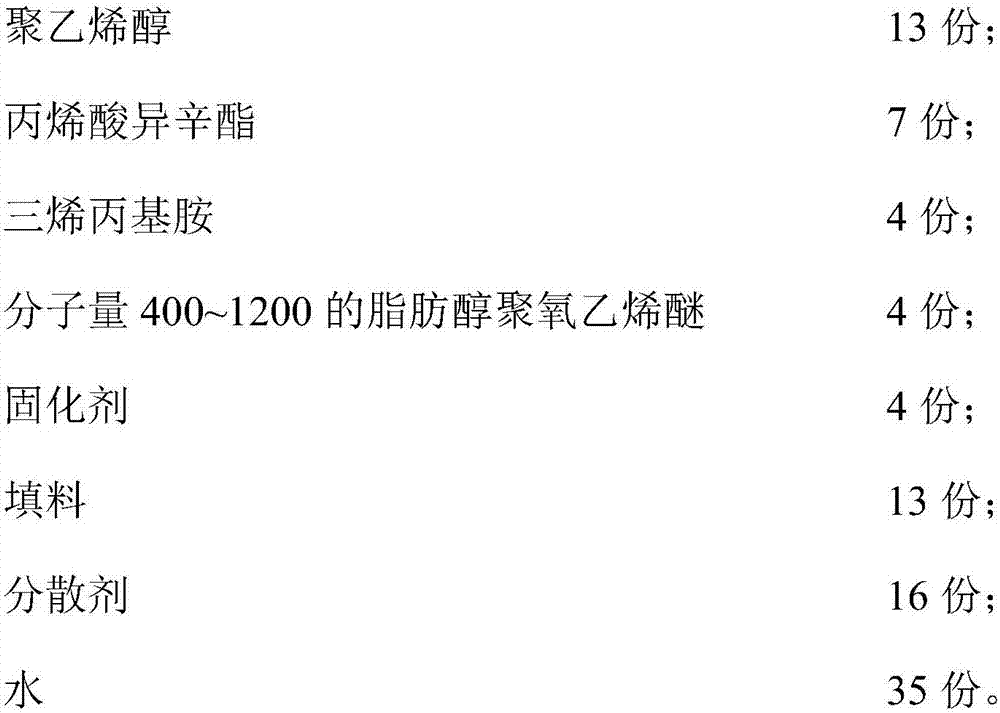

[0039] This embodiment provides a water-based flame-retardant coating and a preparation method thereof, and the water-based flame-retardant coating includes the following components in parts by weight:

[0040] Described water-based flame retardant coating comprises the following components in parts by weight:

[0041]

[0042]

[0043]Wherein, the relative molecular weight of the polyvinyl alcohol is 1700-2000; the curing agent is a blocked water-dispersible polyacetate and melamine, and its weight ratio is 1:2; the filler is titanium dioxide; the The dispersant described above is a silicone compound.

[0044] The preparation method of described waterborne flame retardant coating is:

[0045] (1) Add water, acrylate and polyvinyl alcohol into the reaction vessel in turn under stirring conditions at a stirring rate of 1000r / min according to the amount of raw material formula, and then add isooctyl acrylate, triallylamine and molecular weight 400 ~1200 fatty alcohol pol...

Embodiment 3

[0048] This embodiment provides a water-based flame-retardant coating and a preparation method thereof, and the water-based flame-retardant coating includes the following components in parts by weight:

[0049] Described water-based flame retardant coating comprises the following components in parts by weight:

[0050]

[0051]

[0052] Wherein, the relative molecular weight of the polyvinyl alcohol is 1700-2000; the curing agent is a blocked water-dispersible polyacetate and melamine, and its weight ratio is 2:5; the filler is titanium dioxide; the The dispersant described above is a silicone compound.

[0053] The preparation method of described waterborne flame retardant coating is:

[0054] (1) Add water, acrylate and polyvinyl alcohol into the reaction vessel in turn under stirring conditions at a stirring rate of 1200r / min according to the amount of raw material formula, and then add isooctyl acrylate, triallylamine and molecular weight 400 ~1200 fatty alcohol po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com