A kind of recovery method of formaldehyde in prenol system synthesized by supercritical method

A technology of isopentenol and recovery method, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., and can solve the problem of unqualified, unrecyclable and high production costs of 3-alcohol products And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

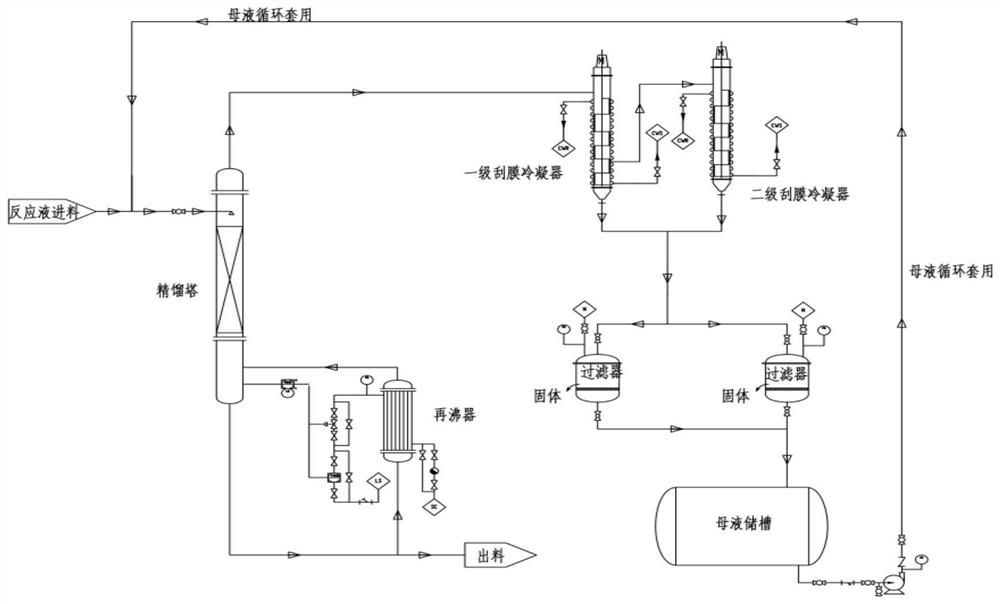

Method used

Image

Examples

Embodiment 1

[0037] Under continuous steady-state operating conditions, the 3-alcohol crude product synthesized by supercritical method is rectified, the formaldehyde content in the crude product is 0.5%, the output flow rate at the top of the tower is 120kg / h, the condenser is a scraping film condensation, and passes Two-stage condensation, in which the area of the first-stage condenser is 15m 2 , the cooling temperature is 20°C, and the area of the second stage condenser is 5m 2 , the cooling temperature is 0°C, the formaldehyde polymer solid on the inner wall of the condenser is scraped into the kettle at the bottom, and finally filtered to obtain the 3-position alcohol. The formaldehyde content is 0.003% as measured by titration. The filtered liquid is returned to the continuous distillation column for further purification.

Embodiment 2-10

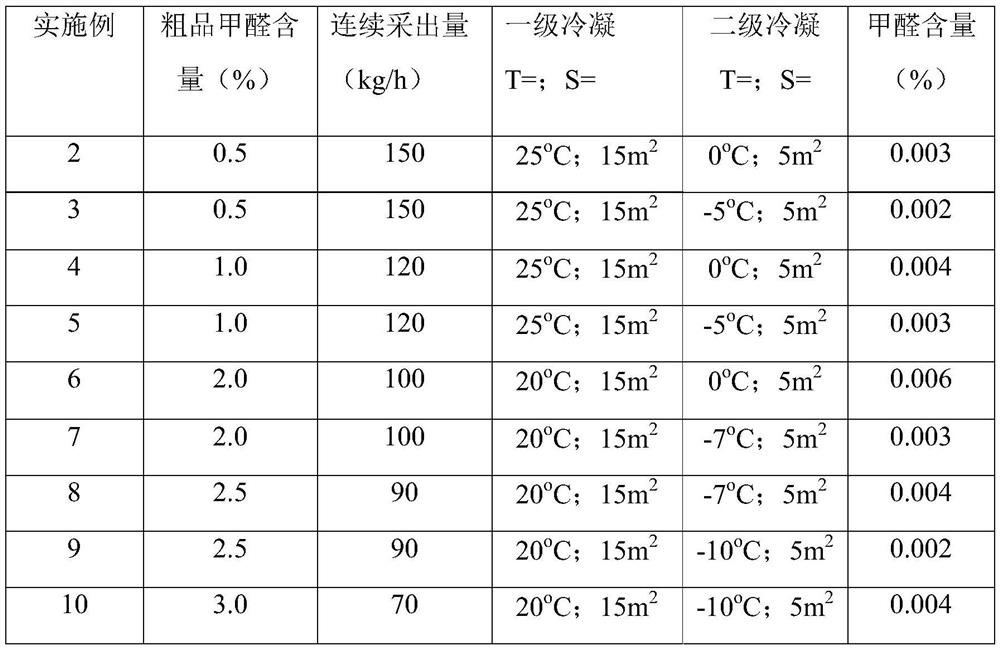

[0039] According to the operating conditions of embodiment 1, change formaldehyde content in the crude product, continuous rectification column output and the cooling temperature of two-stage condenser, the result obtained is as follows:

[0040]

[0041] It can be seen from the results in the above table that when the formaldehyde content in the crude product is high, the continuous recovery and the temperature of the condenser can be appropriately reduced, so as to maintain a high formaldehyde removal efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com