Sewage treatment device

A sewage treatment device and treatment chamber technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the erosion of motors and other controllers, inconvenient transportation and operation, and damage to equipment parts, etc. problems, to achieve the effect of improving water diversion efficiency, convenient operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

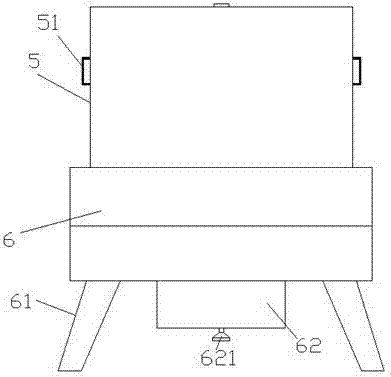

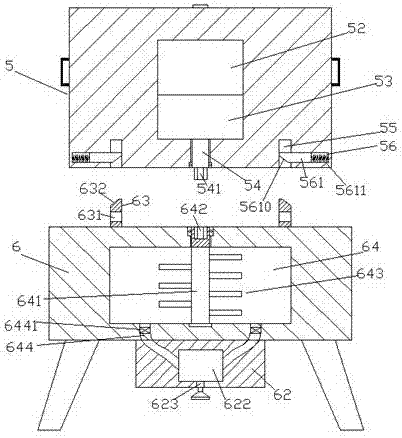

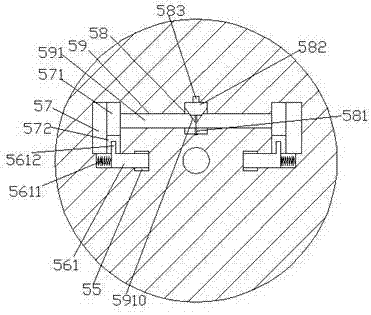

[0023] Such as Figure 1-Figure 6 As shown, a sewage treatment device of the present invention includes a base body composed of an upper base body 5 and a lower base body 6. The lower base body 6 is provided with a treatment chamber 64 inside. Shaft 641, the left and right sides of the top surface of the lower base 6 are oppositely provided with insert locks 63, the upper base 5 is provided with a first motor 52, and the bottom of the first motor 52 is connected with a speed controller 53, so The bottom of the speed controller 53 is fitted with a first rotating shaft 54 that passes through the bottom surface of the upper base body 5 and is connected in a swivel fit. The locking slot 55 opposite to the locking member 63 is provided with locking slots 56 in the side walls of the two sets of locking slots 55, each of which is far away from the locking slot 56. One side of the latch groove 55 is provided with a first sliding chamber 57 extended backwards, and a second sliding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com