Full-automatic bag-clamping supporting machine

A fully automatic, bag-clamping technology, which is used in automatic packaging control, external support, transportation and packaging, etc., can solve the problems of inability to perform normal sewing and sealing, the bag mouth is difficult to flatten without wrinkles, and the packaging effect is poor. Beautiful appearance and the effect of avoiding mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

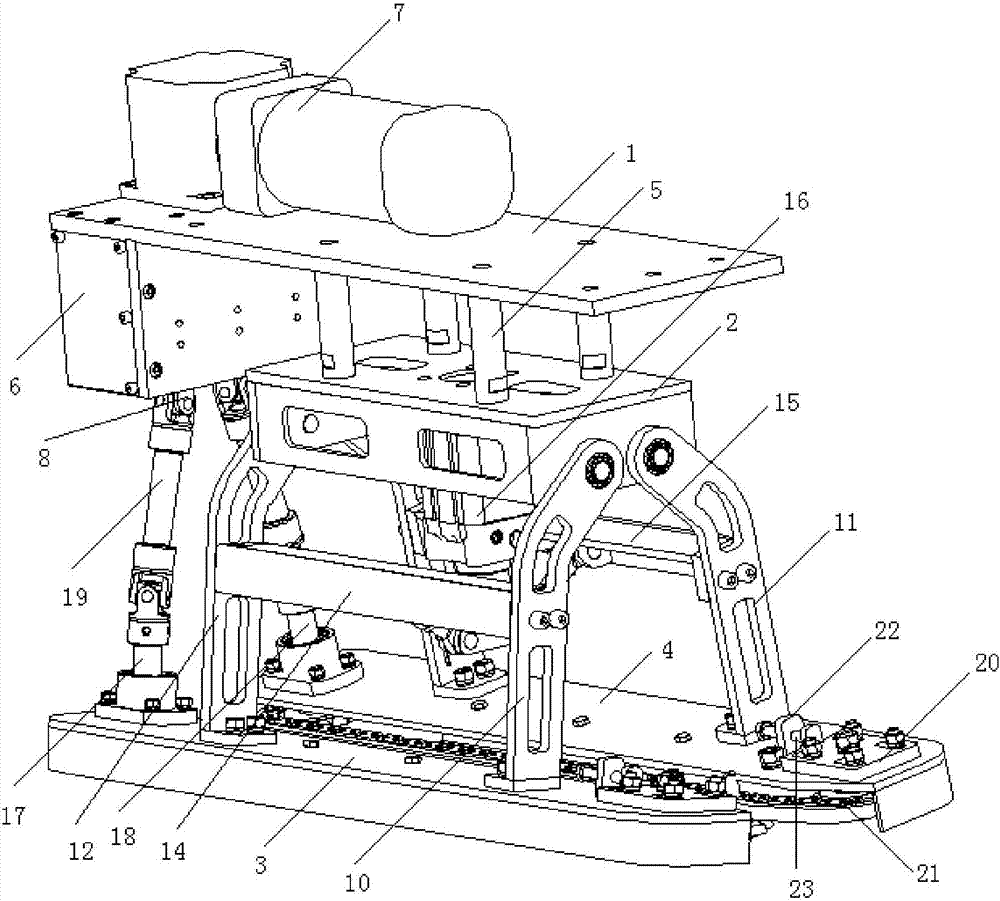

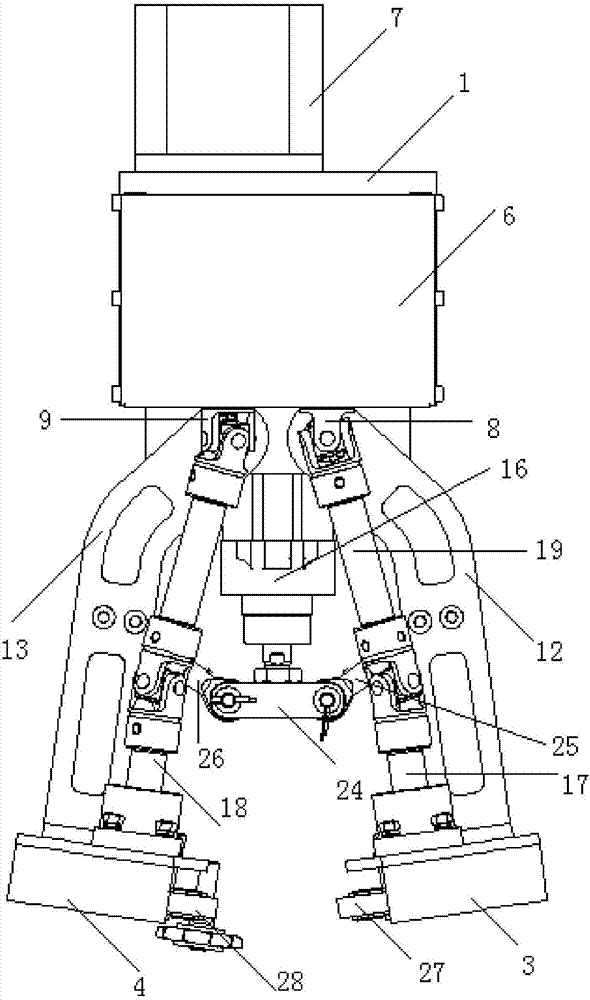

[0012] Referring to the accompanying drawings, a fully automatic bag clamping and supporting machine includes a mounting plate 1, a cylinder seat 2, a left chain seat 3, and a right chain seat 4, and a support rod 5 is fixedly connected between the mounting plate 1 and the cylinder seat 2. A gear box 6 is installed on the plate 1, the input shaft of the gear box 6 is connected with the geared motor 7, the gear box 6 has two left output shafts 8 and right output shafts 9 in opposite directions, and the front and rear ends of the cylinder block 2 are respectively Hinged with front left swing arm 10, front right swing arm 11, rear left swing arm 12, rear right swing arm 13, front left swing arm 10, rear left swing arm 12 lower ends are fixedly connected to the front and rear of left chain seat 3 respectively The lower ends of the front right swing arm 11 and the rear right swing arm 13 are respectively fixedly connected to the front and rear parts of the right chain seat 4, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com