Automatic demolding mold

A technology of automatic demoulding and moulding, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting time, increasing defective products, easy to produce deviation in demoulding, and achieving a stable effect of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

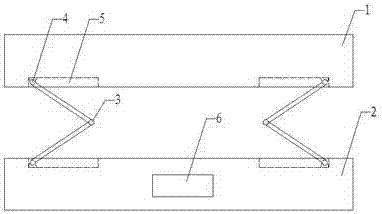

[0014] see figure 1 , the embodiment of the present invention includes: an automatic demoulding mold, including: an upper mold 1, a lower mold 2 and two electric folding rods 3, the upper mold 1 and the lower mold 2 are connected by two electric folding rods 3 The two ends of the electric folding rod 3 are respectively connected with the lower surface of the upper mold 1 and the upper surface of the lower mold 2, and the electric folding rod 3 is used for the upper mold 1 and the lower mold 2 separation.

[0015] The connection between the electric folding rod 3 and the lower surface of the upper mold 1 and the upper surface of the lower mold 2 is equipped with a rotating seat 4, and the rotating seat 4 is used for folding and opening the electric folding rod 3. turn.

[0016] Starting from the rotating seat 4, a rod groove 5 is opened toward the opposite direction of the two rotating seats 4 on the same horizontal plane, and the electric folding rod 3 is matched with the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com