Electric demolding mold

A demoulding and mold technology, applied in the field of electric demoulding molds, can solve the problems of increasing defective products, wasting time, wasting materials, etc., and achieve the effect of product integrity, stable demoulding, and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

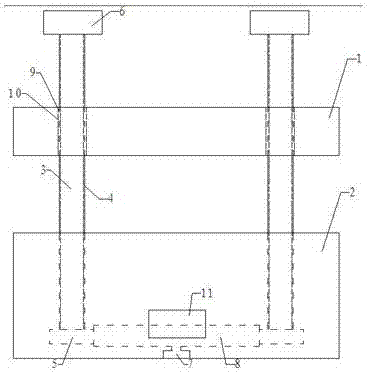

[0013] see figure 1 , the embodiment of the present invention includes: an electric demoulding mold, including: an upper mold 1, a lower mold 2 and two round rods 3, the upper mold 1 and the lower mold 2 are connected through the two round rods 3, The upper die 1 slides up and down on the round rod 3 .

[0014] The round rod 3 is fixed on the upper surface of the lower mold 2, and the two round rods 3 are symmetrically installed on the upper surface of the lower mold 2, so that the force is more balanced when demoulding.

[0015] The outer wall of the round rod 3 is provided with an external thread 4, the bottom end of the round rod 3 is equipped with a driven gear 5, and the top of the round rod 3 is equipped with a stopper 6, and the stopper 6 prevents the upper mold 1 from Demoulding is to slide out the round rod 3 .

[0016] The upper mold 1 is provided with a circular hole 9, and the circular hole 9 is provided with an internal thread 10, and the external thread 4 coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com