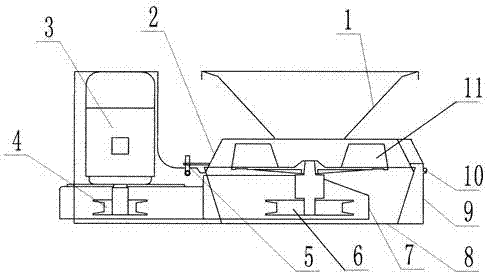

Centrifugal crushing plant

A crushing device and the technology on the other side, applied in the direction of wine preparation, grain processing, alcoholic beverage preparation, etc., can solve the problems of grape juice extrusion, blockage, failure to meet the best requirements of the process, etc., and achieve moderate impact force , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

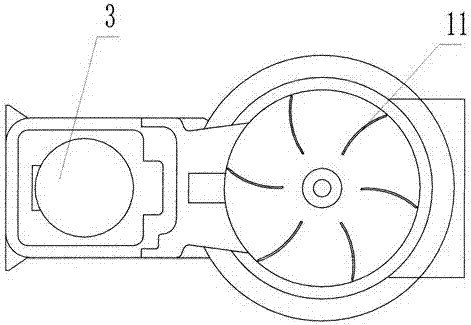

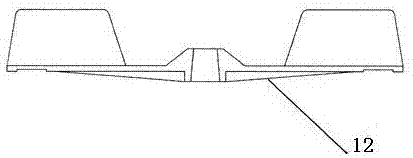

[0008] This technical solution is to crush the sorted grapes, collect the sorted grapes in the casing through the feed port, scatter on the impeller, and be divided by six impellers, when the motor drives the impeller at a constant speed When rotating, the materials scattered on the impeller are driven by the impeller to rotate, and the high-speed rotation of the material fruit produces centrifugal force, which is thrown out through the gap between the impeller blades and hits the inner wall of the casing, and the grape fruit that is broken by the impact force The pellets slide down the inner wall of the casing and are discharged from the discharge port. The speed of the crushing device can be adjusted in two ways. One is to adjust the speed of the motor by the frequency converter. Stepless speed regulation pulley, this speed regulation method is to adjust the width of the pulley through the handle on the motor side, thereby changing the distance between the motor side pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com