Photocatalyst material for absorbing full sunlight spectrum and preparation method thereof

A photocatalyst and full-spectrum technology, which is applied in the direction of luminescent materials, chemical instruments and methods, physical/chemical process catalysts, etc., to improve the photocatalytic effect, improve the utilization rate, and solve the effect of low quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1, preparation of up-conversion material (UC) NaYF by hydrothermal synthesis 4 :Yb,Er:

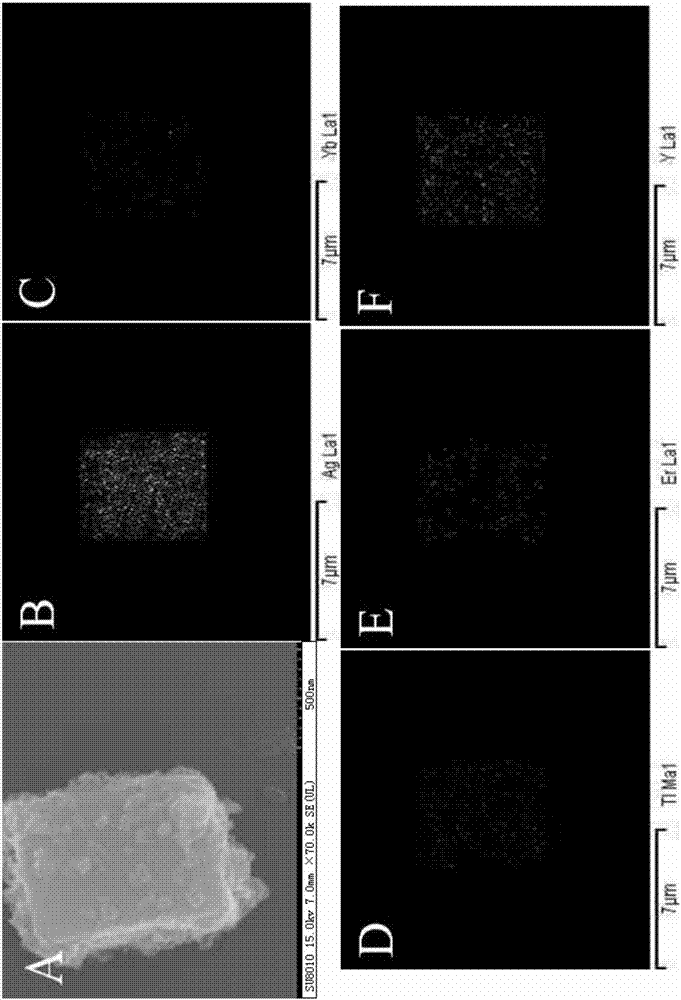

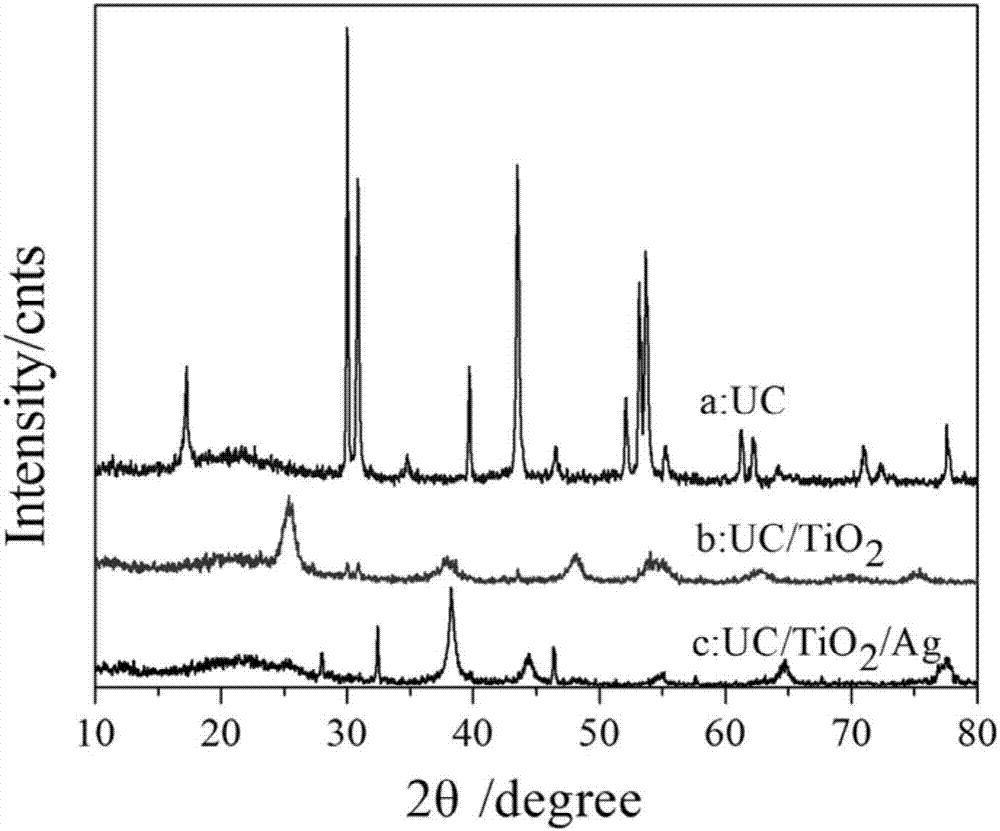

[0025] Weigh 2.519g of sodium fluoride and dissolve it in 50mL of deionized water, shake and dissolve to prepare a 1.2mol / L sodium fluoride solution. Weigh 5.8g of sodium citrate and place it in a clean beaker, add 25mL of deionized water, and dissolve it ultrasonically; then weigh 0.19g of YbCl 3 , 0.38g of YCl 3 , 0.005g ErCl 3 Add to the above solution, and stir magnetically for 30 minutes after ultrasonic dissolution; then measure 25mL, 1.2mol / L sodium fluoride solution and slowly add it to the above mixed solution, continue magnetic stirring for 10min, then transfer the mixed solution to a 60mL reaction kettle placed in an oven at 200°C for 16 hours; after the product was cooled, it was centrifuged, washed with deionized water, and then dried in a drying oven at 180°C for 18 hours; the prepared up-conversion material (UC) NaYF 4 :Yb, Er, NaYF 4 As a host material, dop...

Embodiment 2

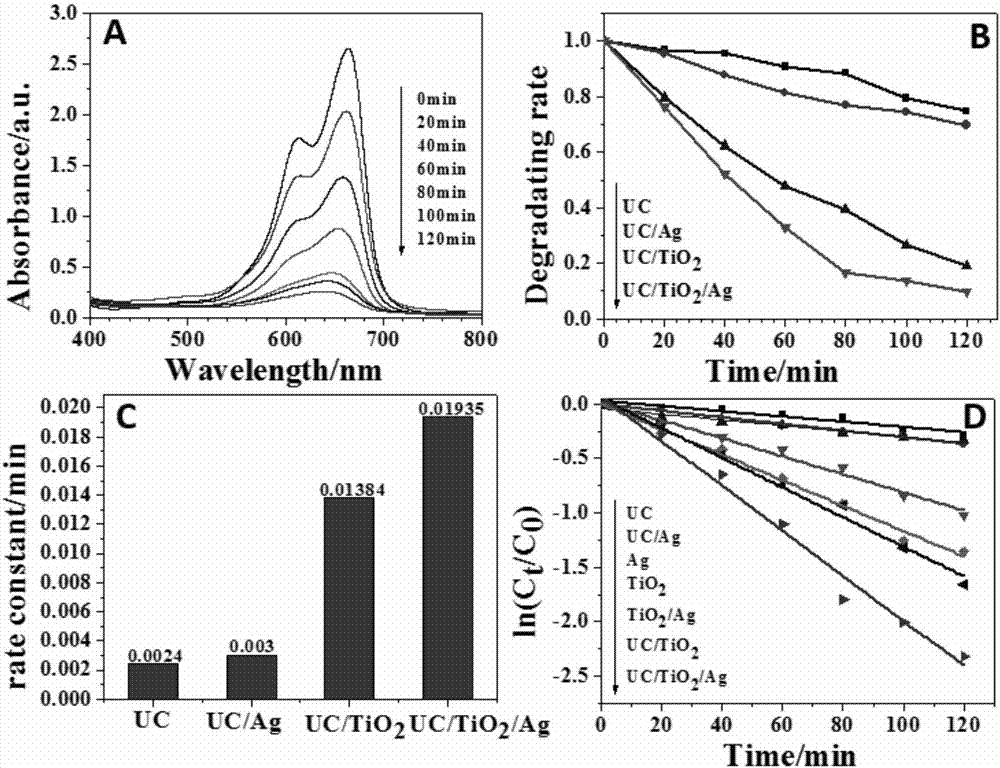

[0033] (1) Prepare 20mg / L methylene blue solution as the degraded product for later use.

[0034] (2) Take 50mL of methylene blue solution in a beaker, and add 0.05g of catalyst, after ultrasonic dispersion, magnetically stir for 1h in the dark to ensure that the dye molecules and photocatalyst reach the adsorption-desorption equilibrium.

[0035] (3) Put the target degradation product in (2) above in a photocatalytic degradation device, and keep stirring the solution during the reaction. Take 3 mL of the reaction solution every 20 minutes and put it into a centrifuge tube for centrifugation. Take the supernatant and measure its absorption peak in a cuvette and compare the change of the absorption peak before and after degradation.

[0036] image 3 A is the above methylene blue solution in the composite UC / TiO 2 Under the photocatalytic degradation of / Ag, the characteristic peak intensity at 665nm gradually weakens with time in the ultraviolet-visible spectrum, indicating ...

Embodiment 3

[0040] Step 1, preparation of up-conversion material (UC) NaYF by hydrothermal synthesis 4 :Yb,Er:

[0041] Weigh 2.519g of sodium fluoride and dissolve it in 50mL of deionized water, shake and dissolve to prepare a 1.2mol / L sodium fluoride solution. Weigh 5.8g of sodium citrate and place it in a clean beaker, add 25mL of deionized water, and dissolve it ultrasonically; then weigh 0.19g of YbCl 3 , 0.38g of YCl 3 , 0.005g ErCl 3 Add to the above solution, and stir magnetically for 30 minutes after ultrasonic dissolution; then measure 25mL, 1.2mol / L sodium fluoride solution and slowly add it to the above mixed solution, continue magnetic stirring for 10min, then transfer the mixed solution to a 60mL reaction kettle placed in an oven at 160°C for 24 hours; after the product was cooled, it was centrifuged, washed with deionized water, and then dried in a drying oven at 160°C for 24 hours; the prepared up-conversion material (UC) NaYF 4 :Yb, Er, NaYF 4 As a host material, dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com