Bag taking-off plate and beverage brewing equipment with bag taking-off plate

A technology of unwrapping and brewing, which is applied in the field of unwrapped boards, can solve the problems of insufficient structure, high assembly requirements, and many parts involved, and achieve the effect of reducing costs and simplifying the unwrapped structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

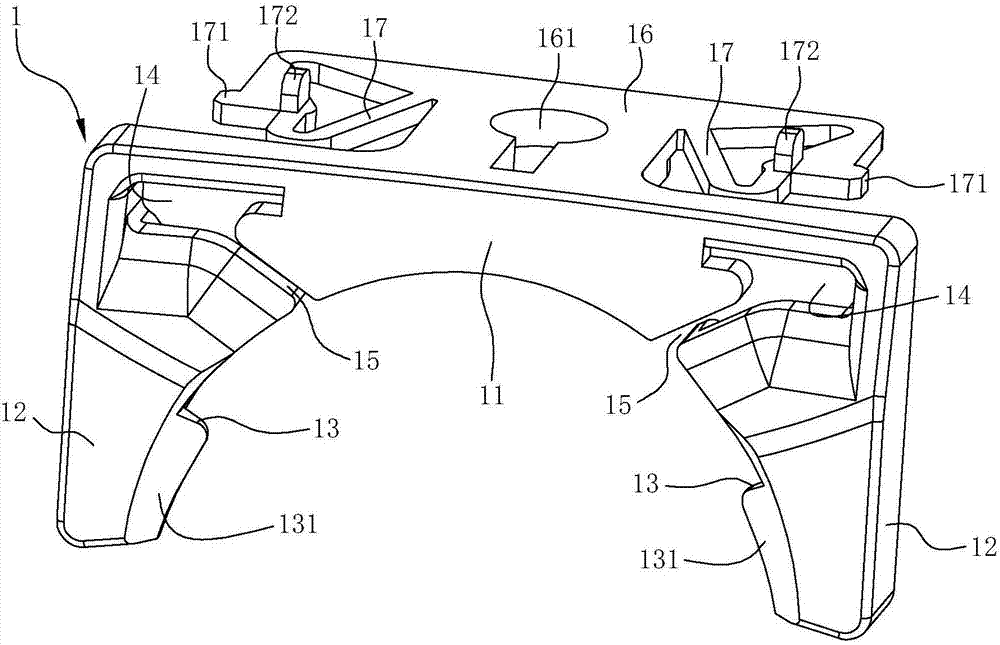

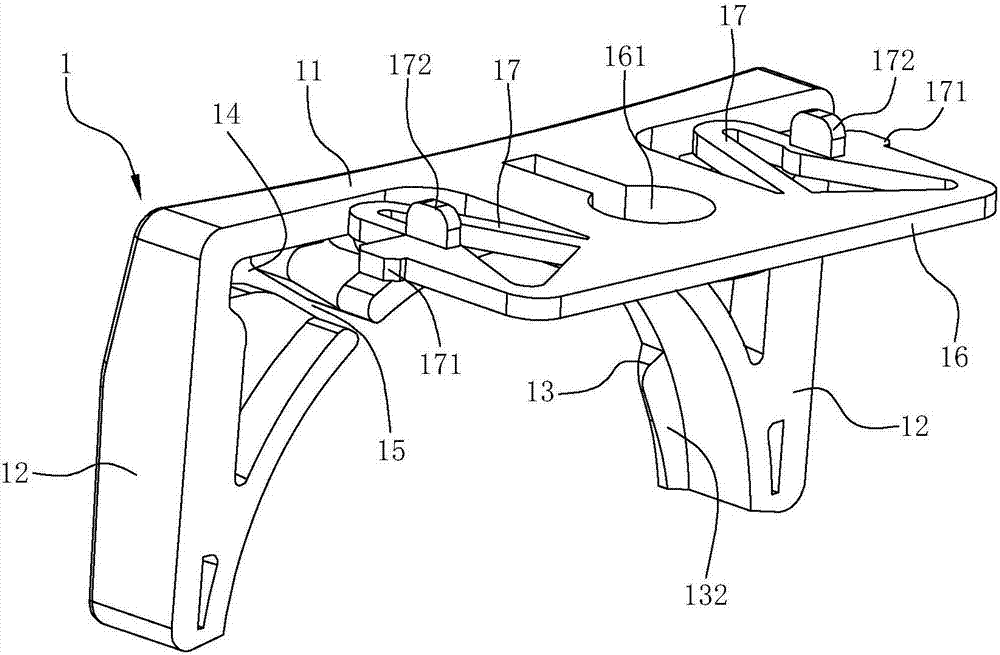

[0035] like Figures 1 to 2 shown, is a preferred embodiment of the stripping board of the present invention.

[0036] An unpacking board 1 is used to be installed on the base of a beverage brewing device. The unpacking board 1 has a base portion 11, and the left and right sides of the base portion 11 have two downwardly extending arm portions 12. The arm portion 12 and the base portion 11 It is integrally formed, so that the stripping plate 1 can be integrally injection-molded. The arm portion 12 itself has elasticity, which can make the arm portion 12 expand outward and automatically reset when retracted. The junction of the arm portion 12 and the base portion 11 There is a through hole 14 penetrating through the front and rear, and the inner side of the hole 14 is provided with a notch 15 . The arrangement of the through holes 14 makes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com