Cleaning brush for cooling pieces of locomotive traction component

A heat sink and cleaning brush technology, applied in the field of cleaning brushes, can solve the problems of dust easily adhering to the heat sink, insufficient cleaning of the heat sink, affecting the heat exchange efficiency of the heat sink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

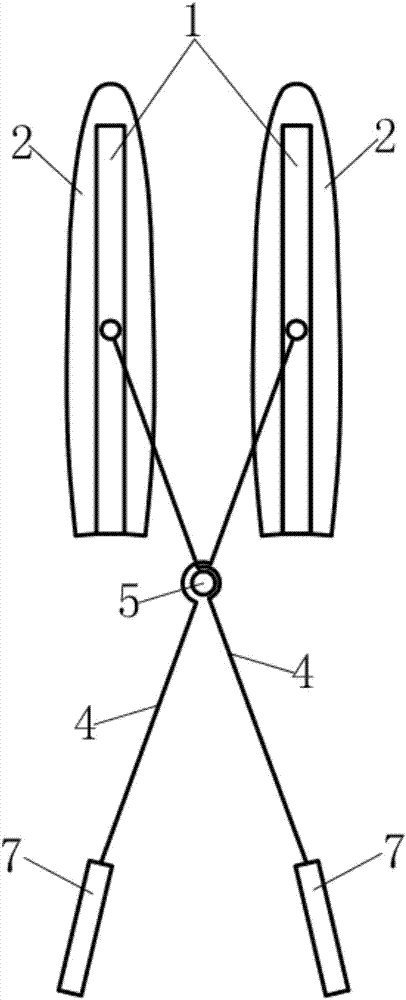

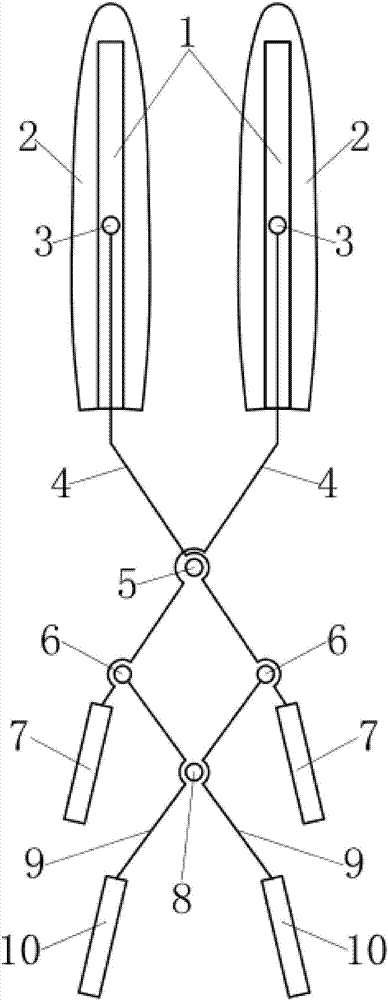

[0035] In order to achieve the purpose of the present invention, as figure 1 As shown, a cooling fin cleaning brush for traction parts of a locomotive includes two independent cleaning parts. The cleaning parts extend into the groove formed by adjacent cooling fins. The cleaning parts contact the cooling fins and clean them; The parts are respectively attached to two independent substrates 1; the two first connecting rods 4 are intersected, and the intersections are connected by the second hinge 5, and one ends of the two first connecting rods 4 are respectively connected to the two substrates 1; The other end of the first connecting rod 4 not connected to the two base plates 1 is fixedly connected to the two first handles 7 .

[0036] The beneficial effect of adopting the above-mentioned technical solution is that: the base plate 1 has a certain strength, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com