Device and method for cyclically utilizing pickled vegetable pickling liquid

A technology of pickling and pickling, which is applied in the field of recycling pickling liquid, which can solve the problems of high nitrite content and long cycle of pickling liquid, and achieve the reduction of environmental pollution, shortening of production cycle, and reduction of water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

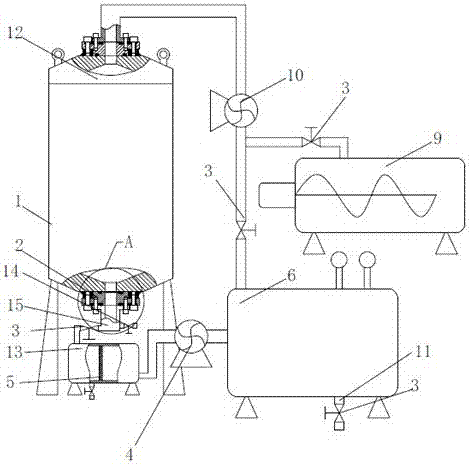

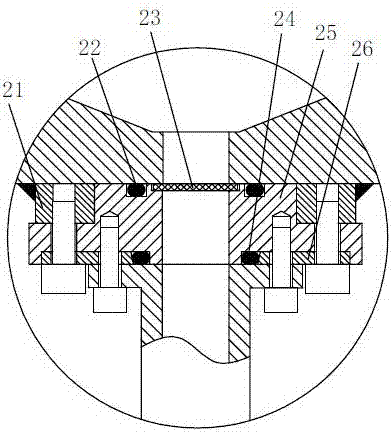

[0019] combined with Figure 1-2 Shown, a kind of device that recycles pickled vegetable pickling liquid, comprises tank body 1, filter box 13, front circulation pump 4, pickling liquid storage tank 6, back circulation pump 10, sealing tank cover 12; Sealing tank cover 12 is set There is a water inlet, which is sealed and connected to the upper end of the tank body 1; a water outlet is provided at the lower end of the tank body 1, and a sealing device 2 is provided at the water outlet; a water outlet pipe is connected between the inlet of the filter box 13 and the water outlet of the tank body 1 15, the outlet pipe 15 is provided with a manual valve 3; the outlet pipe 15 is also connected to a drain pipe, and the drain pipe is provided with a manual drain valve 14; the inside of the filter box 13 is provided with a filter screen 5, and the filter box 13 The outlet is communicated with the inlet of the soaking liquid storage tank 6 through the pipeline provided with the front c...

Embodiment 2

[0024] For implementing the present invention better, reduce the precipitation in soaking liquid, the filter core in the described filter screen 5 is PP filter core, and PP filter core is a kind of adopting nontoxic and odorless polypropylene as raw material, through heating and melting, spraying, traction, The filter material made by receiving molding. The PP filter element has a deep filtration structure with uniform pore size, sparse outside and dense inside, and has the excellent characteristics of high filtration efficiency and acid and alkali resistance. It can effectively remove suspended solids, particles and other impurities in the liquid.

[0025] In order to further effectively recycle the kimchi pickling liquid and supplement the lost part of the kimchi pickling liquid, the outlet of the pickling liquid storage tank 6 is provided with a manual valve 3, and the rear circulation pump 10 and the pickling liquid storage tank 6 A supply box 9 is connected in parallel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com