Pump monitoring device for methyl alcohol recovery technological process

A methanol recovery and monitoring device technology, applied to pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve problems such as life and property risks, leakage cannot be detected in time, explosions, etc., to protect life and property safety, improve recycling production efficiency, and avoid poisoning or explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

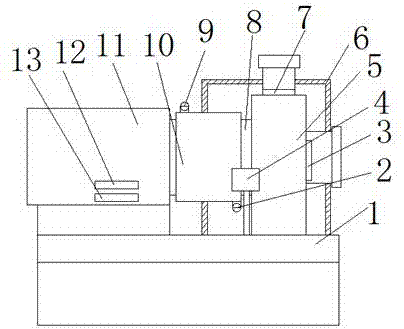

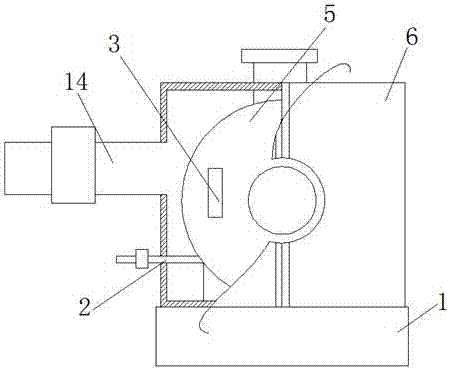

[0016] refer to Figure 1-2 , a pump monitoring device for a methanol recovery process, comprising a base 1, the top side of the base 1 is connected with a pump volute 5 through bolts, one side of the pump volute 5 is connected with a connecting sleeve 8 through bolts, and one end of the connecting sleeve 8 The driving motor 11 is connected by bolts, and the bottom of the driving motor 11 is connected with the base 1 by bolts, and the outer wall of one side of the driving motor 11 is respectively connected with a motor vibration meter 12 and a motor thermometer 13 by screws, and the motor thermometer 13 is located at the motor measuring station. Below the vibrator 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com