Cotton core forming process

A molding process and cotton core technology, applied in medical science, apparel, underwear, etc., can solve problems such as increased production costs, unfavorable production activities, frequent failure rates, etc., to prevent loosening, save production space and sites, and ensure stable transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

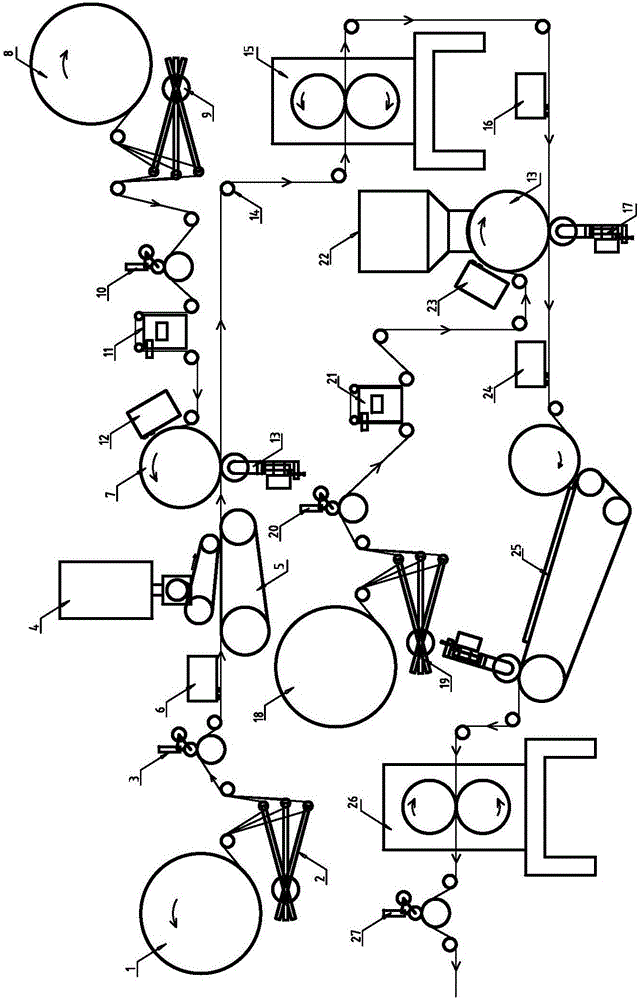

[0014] The present invention is further described through specific implementation methods, wherein the material tension control mechanism, material pressure feeding mechanism, suction box transmission mechanism, edge correction mechanism, edge folding mechanism and other machines are all existing machines, so their structures will not be described in detail.

[0015] refer to figure 1 , the preferred cotton core molding process of the present invention comprises the following steps:

[0016] (1) Send the starting end of the fluffy non-woven material roll 1 of the middle layer to the first material pressure-feeding mechanism 3 after the first material tension control mechanism 2 controls the conveying tension, and then the first material pressure-feeding mechanism 3 pushes the middle layer The fluffy non-woven fabric is sent to the adsorption box transmission mechanism 5 below the polymer continuous application mechanism 4, and the middle layer fluffy non-woven fabric is first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com