Lithium-ion battery capable of being disassembled and recycled conveniently, manufacturing method and disassembled and recycled method

A lithium-ion battery and recycling method technology, applied in the field of dismantling and recycling, can solve the problems of difficult disassembly and recycling of electrode materials and current collectors, potential safety hazards, environmental pollution, etc., and achieves low internal resistance, improved recovery rate, and volumetric energy density. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

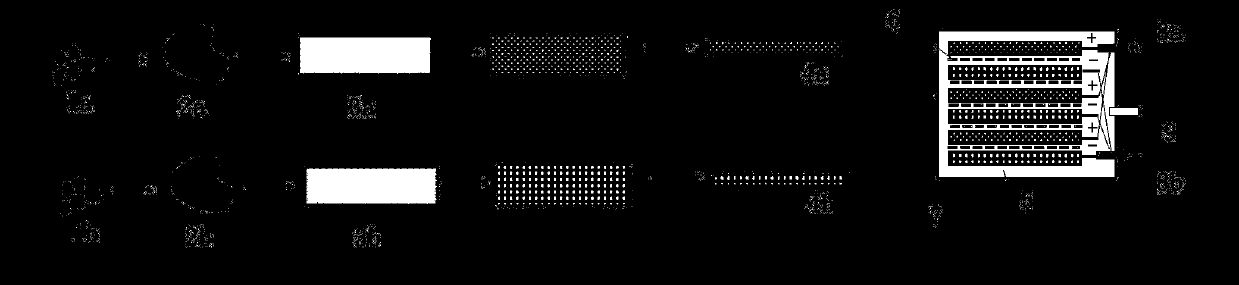

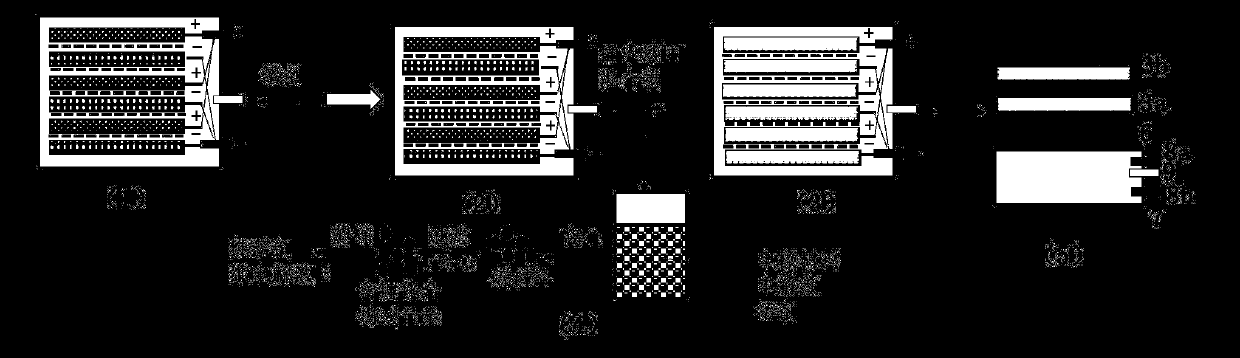

Embodiment 1

[0036] refer to figure 1 , the positive electrode material 1a (lithium manganese oxide, particle size 30 microns) is made into positive electrode slurry 2a according to the conventional method; it is filled into the porous aluminum current collector 3a by extrusion (the size of the void is the maximum particle size of the positive electrode material 1a 10 times of that), and through rolling, the two are in close contact to form the positive electrode composite pole piece 4a. Negative electrode material 1b (graphite, particle size 10 microns) is made into negative electrode slurry 2b according to a conventional method; it is filled into porous copper current collector 3b (the void size is 50% of the maximum particle diameter of negative electrode material 1b) by extrusion. times), and through rolling, the two are in close contact to form the negative electrode composite pole piece 4b. The above composite pole pieces 4a and 4b are respectively welded with aluminum tab 8a and co...

Embodiment 2

[0040] refer to figure 1, the positive electrode material 1a (lithium phosphate doped with carbon nanotubes, the mass fraction of carbon nanotubes is 1%, and the particle size is 0.01 micron) is made into positive electrode slurry 2a according to a conventional method; it is filled by extrusion into the voids of the porous aluminum current collector 3a (the void size is 10 times the maximum particle diameter of the positive electrode material 1a), and make the two closely contact by rolling to form the positive electrode composite pole piece 4a. Negative electrode material 1b (graphite, particle size 30 microns) is made into negative electrode slurry 2b according to a conventional method; it is filled into porous copper current collector 3b (the void size is 30 microns of the maximum particle diameter of negative electrode material 1b) by extrusion. times), and through rolling, the two are in close contact to form the negative electrode composite pole piece 4b. The above comp...

Embodiment 3

[0044] refer to figure 1 , the positive electrode material 1a (nickel cobalt lithium manganese oxide doped with graphene and superP, the mass fraction of graphene and superP is 0.1% and 3%, particle size 0.1 micron) is made into positive electrode slurry 2a according to a conventional method; Fill it into the gap of the porous aluminum current collector 3a (the size of the gap is 20 times the maximum particle size of the positive electrode material 1a), and make the two closely contact by rolling to form a positive composite pole piece 4a. Negative electrode material 1b (silicon carbon negative electrode material, particle size 30 microns) is made into negative electrode slurry 2b according to conventional methods; it is filled into porous copper current collector 3b (the size of the void is the largest in negative electrode material 1b) by extrusion. 30 times the size of the particles), and by rolling, the two are in close contact to form the negative electrode composite pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com