Automatic layout method of building pipeline system

A pipeline system and automatic discharge technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low efficiency, many errors, and high requirements for discharge personnel, so as to reduce the quantity, make discharge reasonable, The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

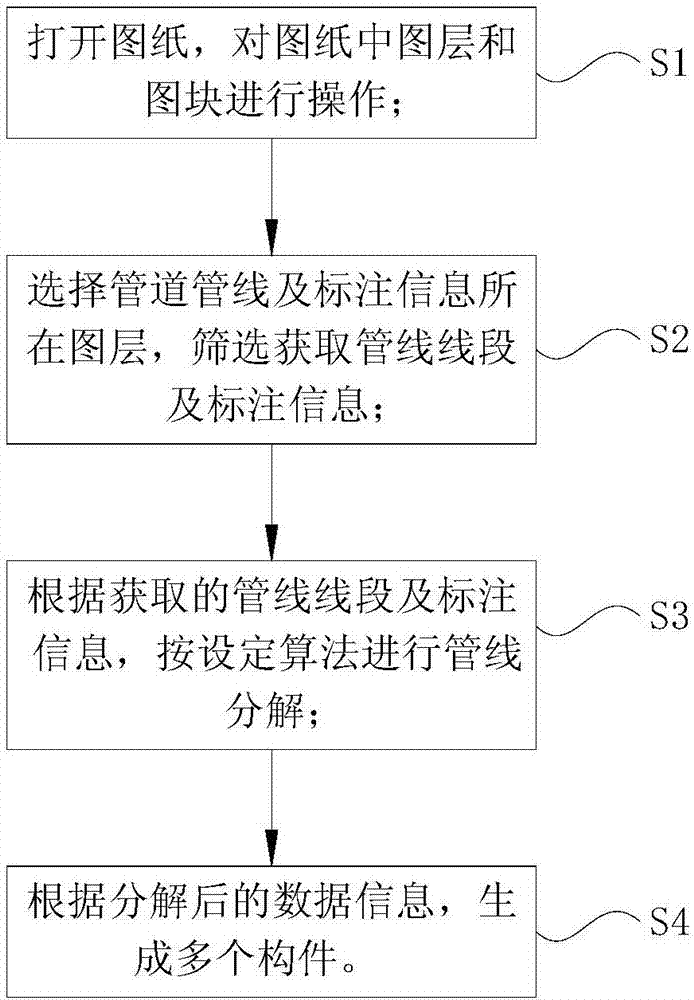

[0032] In the present invention, by obtaining the coordinate position of the line segments in the drawings (such as CAD plane drawings, BIM models based on the REVIT platform, etc.) This information includes the specification and size of the pipeline (such as the air duct), the installation position, and the cross information of the pipeline; then, from the professional point of view of mechanized processing, the constructed engineering information is decomposed into a series that can be used for actual processing This component has a series of complete attributes that can be used for actual processing, including pipe segment type, specification, installation position, material, process, system number, etc., and regenerates drawings in the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com