Servo lifting roller machine

A rolling bed and servo motor technology, which is applied in the field of lifting rolling bed, can solve the problems of large space occupation of the lifting mechanism, large replacement man-hours, consumption, etc., and achieve the effects of ensuring the stability of the lifting, reducing the occupied area, and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

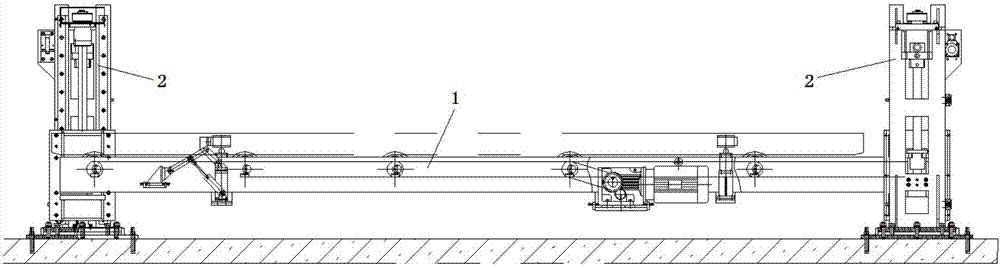

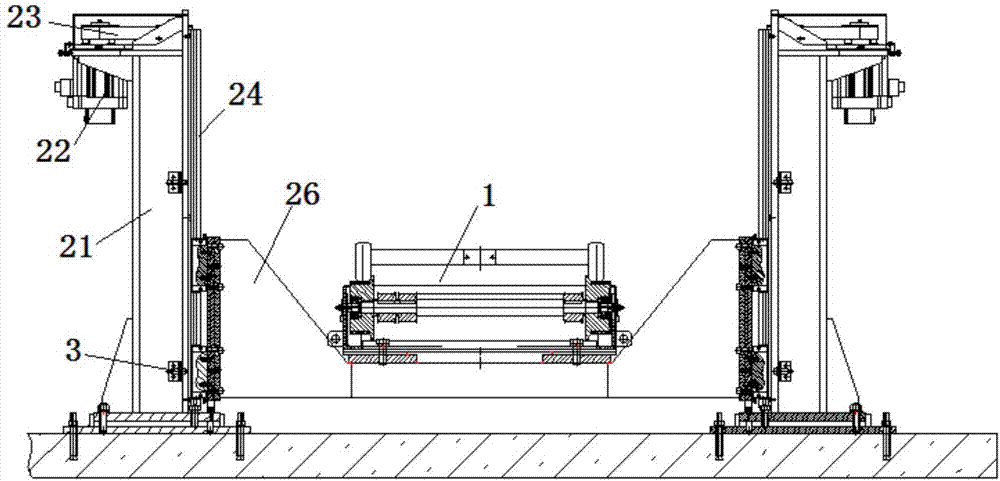

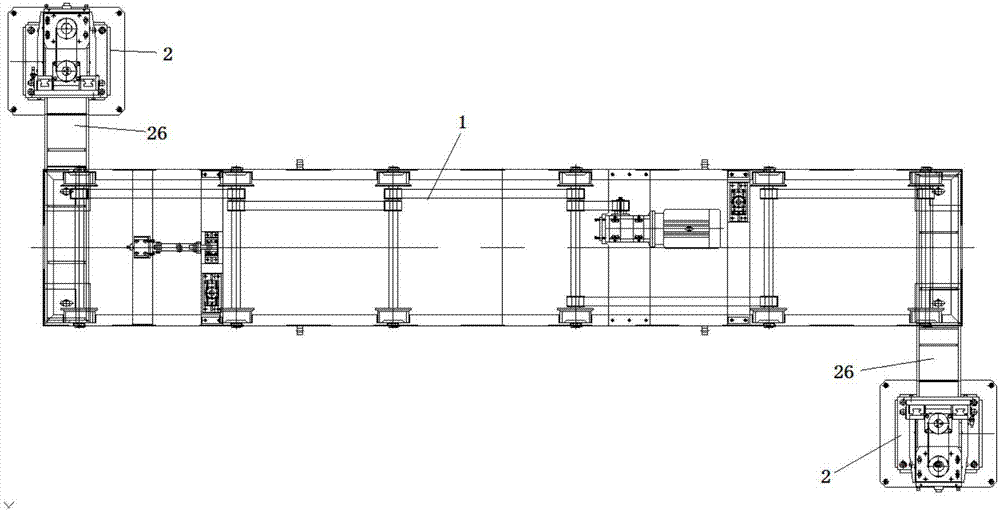

[0026] It can be seen from the accompanying drawings of the description of the present invention that a servo lifting roller bed of the present invention includes a horizontal conveying roller bed 1 and a servo lifting device 2 for lifting the horizontal conveying roller bed 1 in the vertical direction. The servo lifting device 2 includes at least two , and arranged symmetrically with respect to the central axis of the horizontal conveying roller bed 1; each servo lifting device 2 includes a vertical base 21, a servo motor 22, a guide rail slider mechanism 24, a ball screw 25 and a lifting bracket 26; The guide rail of block mechanism 24 and the leading screw of ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com