Automatic screw heat embedding machine

A screw, automatic technology, applied in the field of automatic screw heat burying machine, can solve the problems of unfavorable production product quality assurance, loss of electrical connection blocks, reduced production efficiency, etc., to avoid the replacement of the operation process, no consumables, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further described below with reference to the accompanying drawings and specific embodiments.

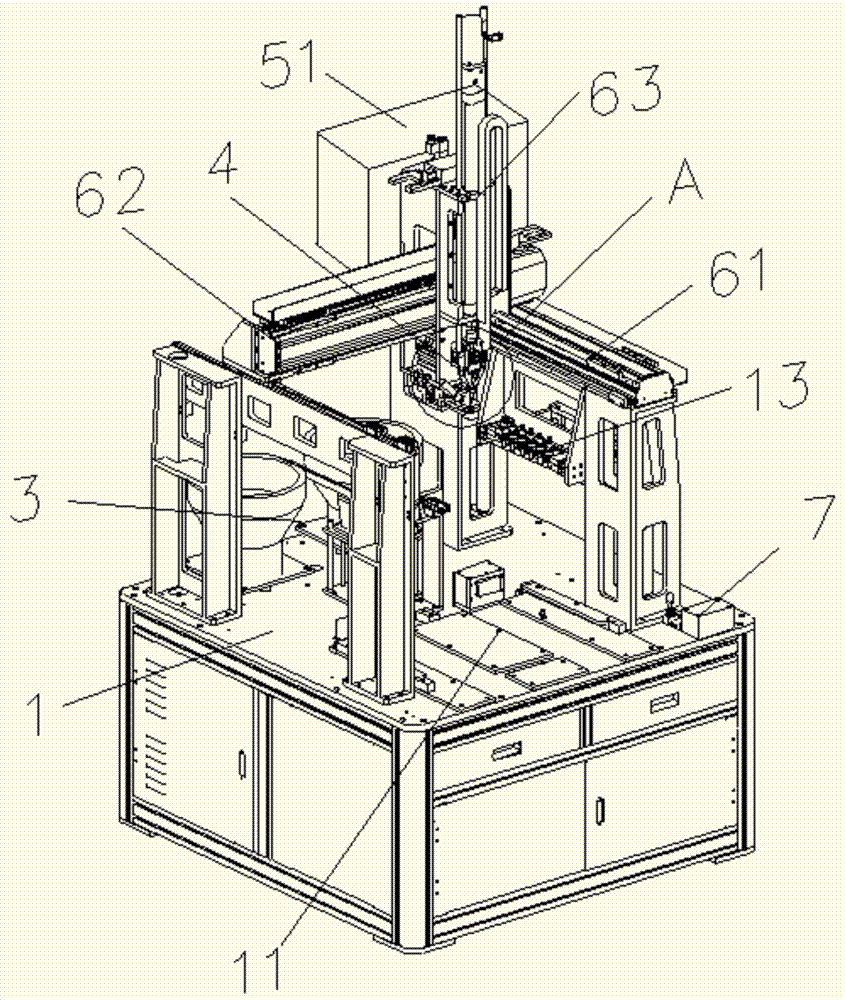

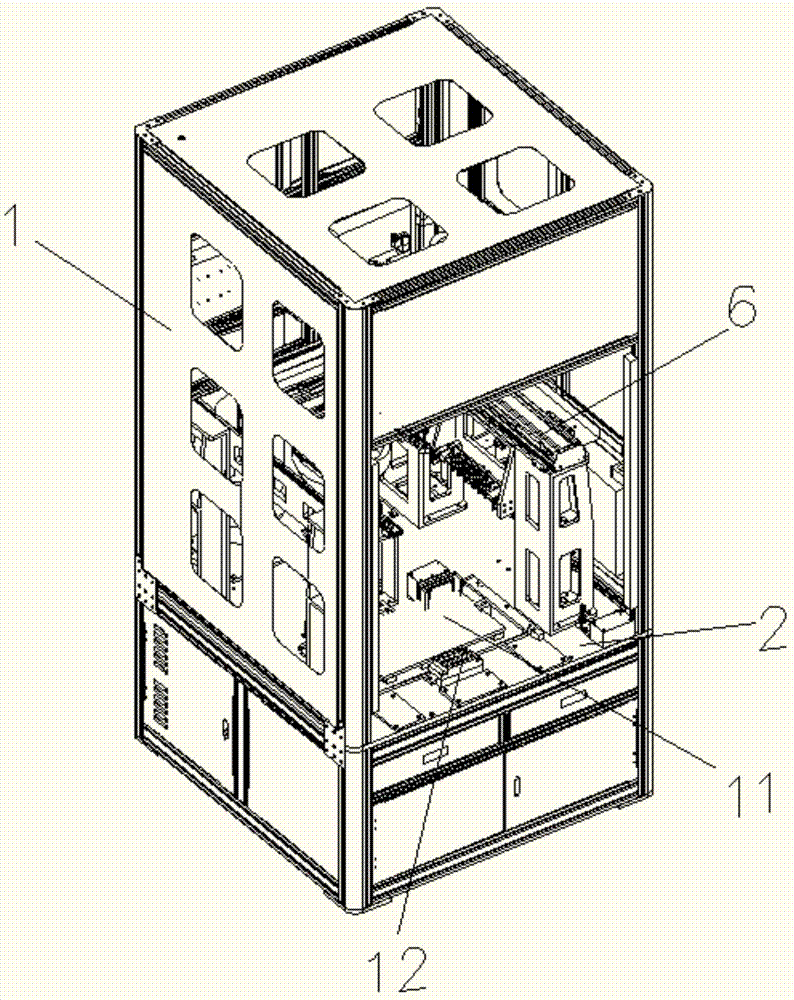

[0028] like image 3 As shown, the device uses metal rods to form a cuboid frame. In order to ensure a stable state during processing, a plurality of rectangular plates are connected to the outside of the frame to form a casing 1, which ensures the safety of the processing process. At this time, rectangular plates are connected at corresponding heights inside the casing 1 , thereby forming the workbench 2 . An opening of the casing 1 is a working port for the staff, and the staff is located at the opening to perform the control operation of the thermal burial operation. Depend on figure 1 As shown, the workbench 2 is provided with a switch 7 at a corresponding position, and the worker controls the thermal burial operation through the switch 7 .

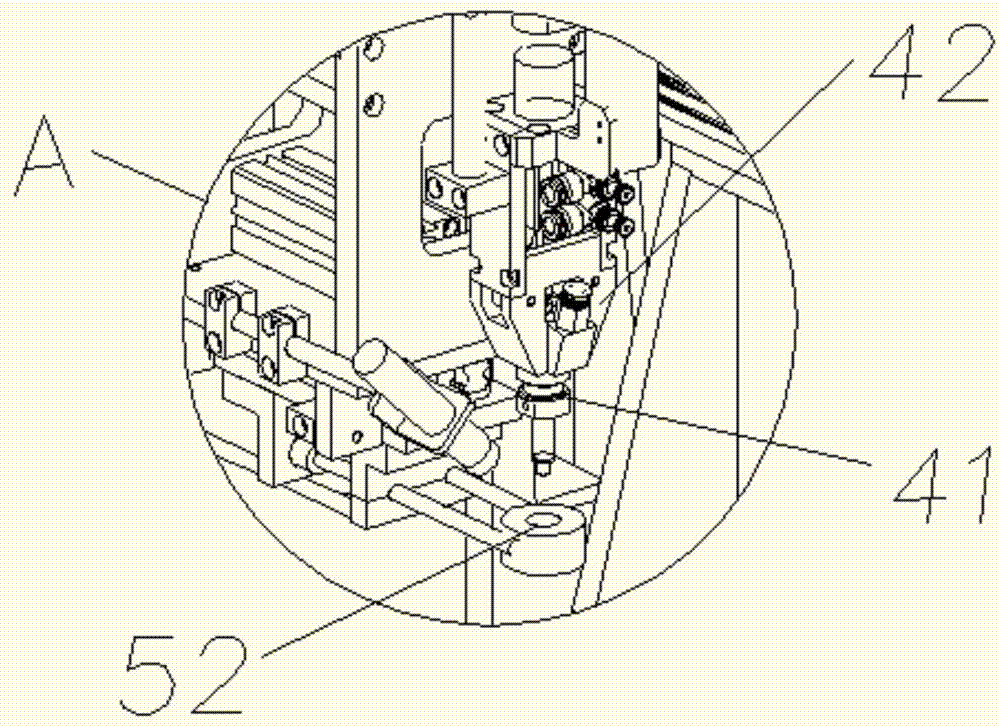

[0029] The worktable 2 is provided with four installation rods facing upward, and the X-axis rails 61 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com