Glaze spraying device for production of ceramic products

A glaze spraying and product technology, which is applied to the field of glaze spraying devices for the production of ceramic products, can solve the problems of chromatic aberration, waste of glaze, large glaze thickness, etc., and achieve the effects of convenient installation, convenient recycling, and reduced maintenance difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

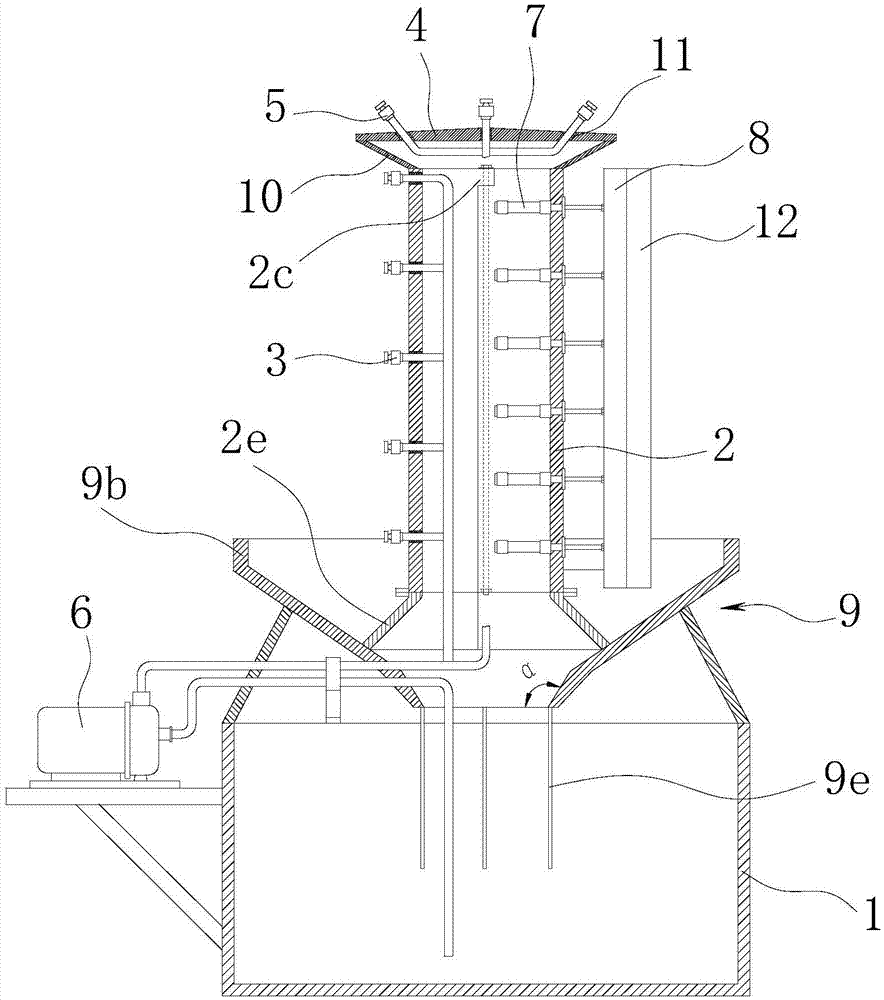

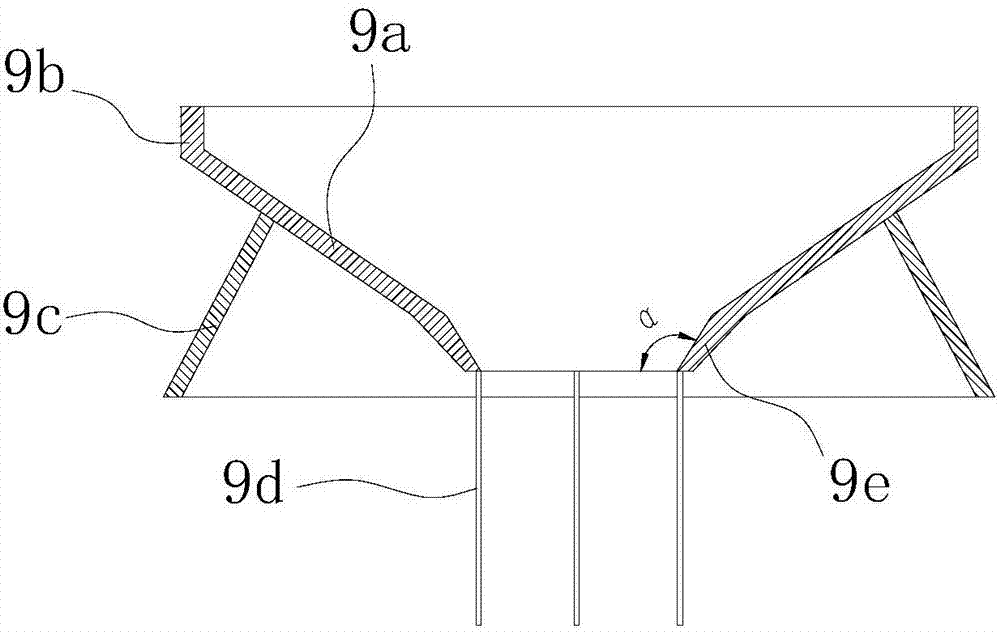

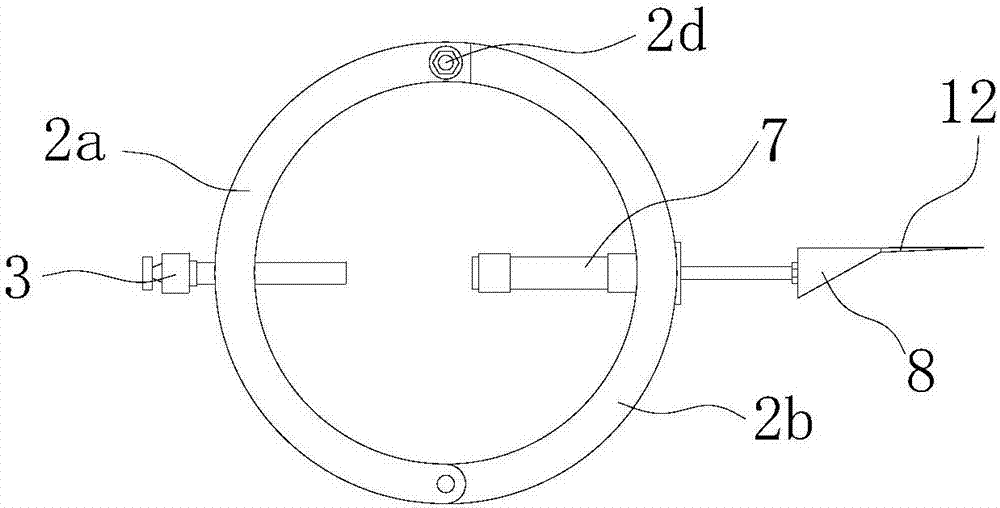

[0018] refer to Figure 1 to Figure 3 As shown, a kind of glaze spraying device for the production of ceramic products of the present invention includes a liquid storage tank 1, and the liquid storage tank 1 is provided with a guide cover 9, and an installation cylinder 2 is arranged in the guide cover 9. The installation cylinder 2 is hinged by two mutually matched left arc-shaped plates 2a and right arc-shaped plates 2b. The end of the right arc-shaped plate 2b away from the hinged part is provided with a connecting groove, and the left arc-shaped plate 2a is provided with The connection protrusion 2c adapted to the connection groove is provided with a first through hole along the vertical direction on the connection protrusion 2c, and a second through hole matched with the first through hole is provided on the right arc plate 2b , the left arc-shaped plate 2a and the right arc-shaped plate 2b are fixedly connected by locking bolts 2d, and the free ends of the locking bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com