Heating recovery device for partial depression of steel

A recovery device and heating technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large labor and time, unsatisfactory effect, etc., and achieve the effect of providing heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

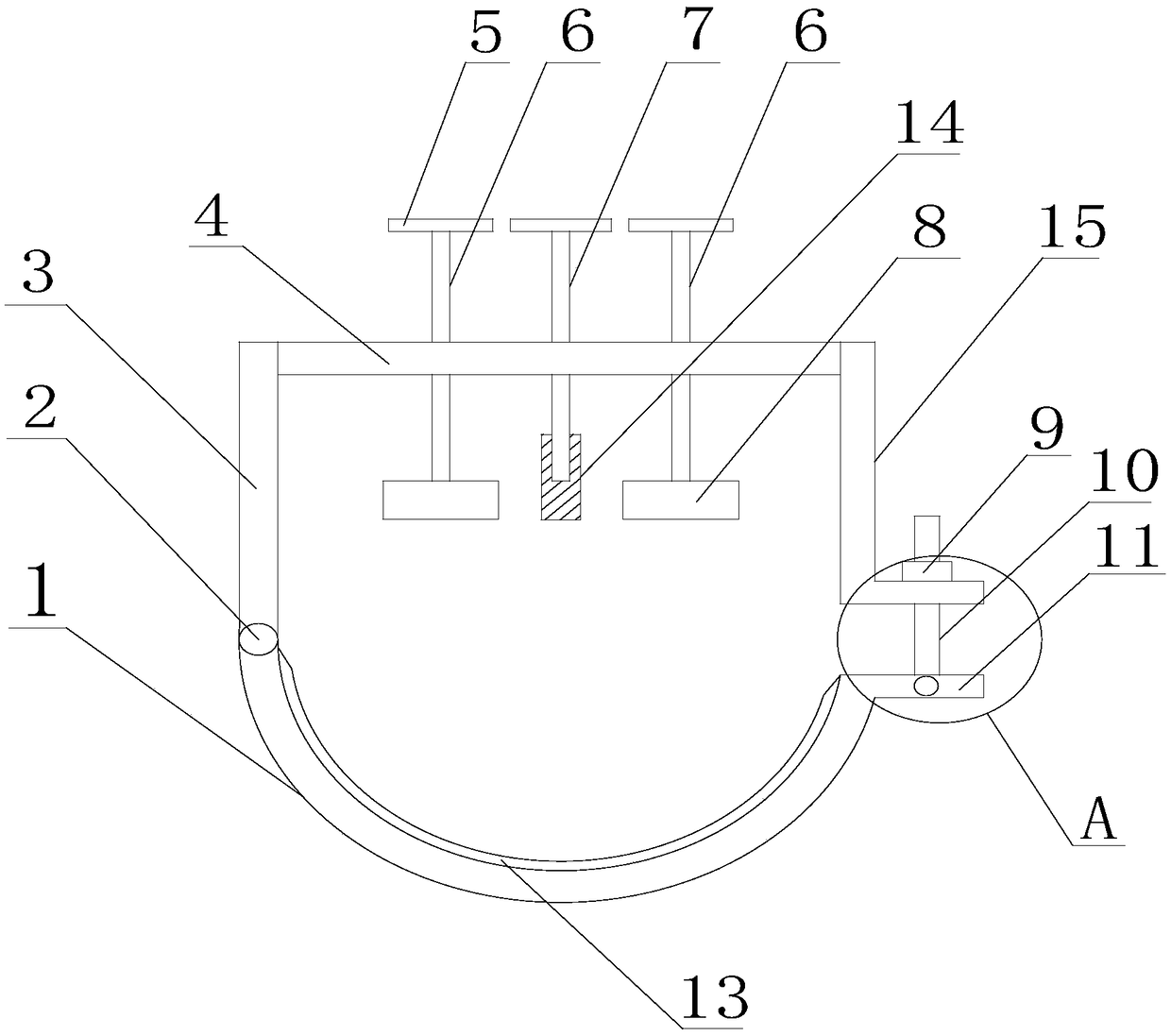

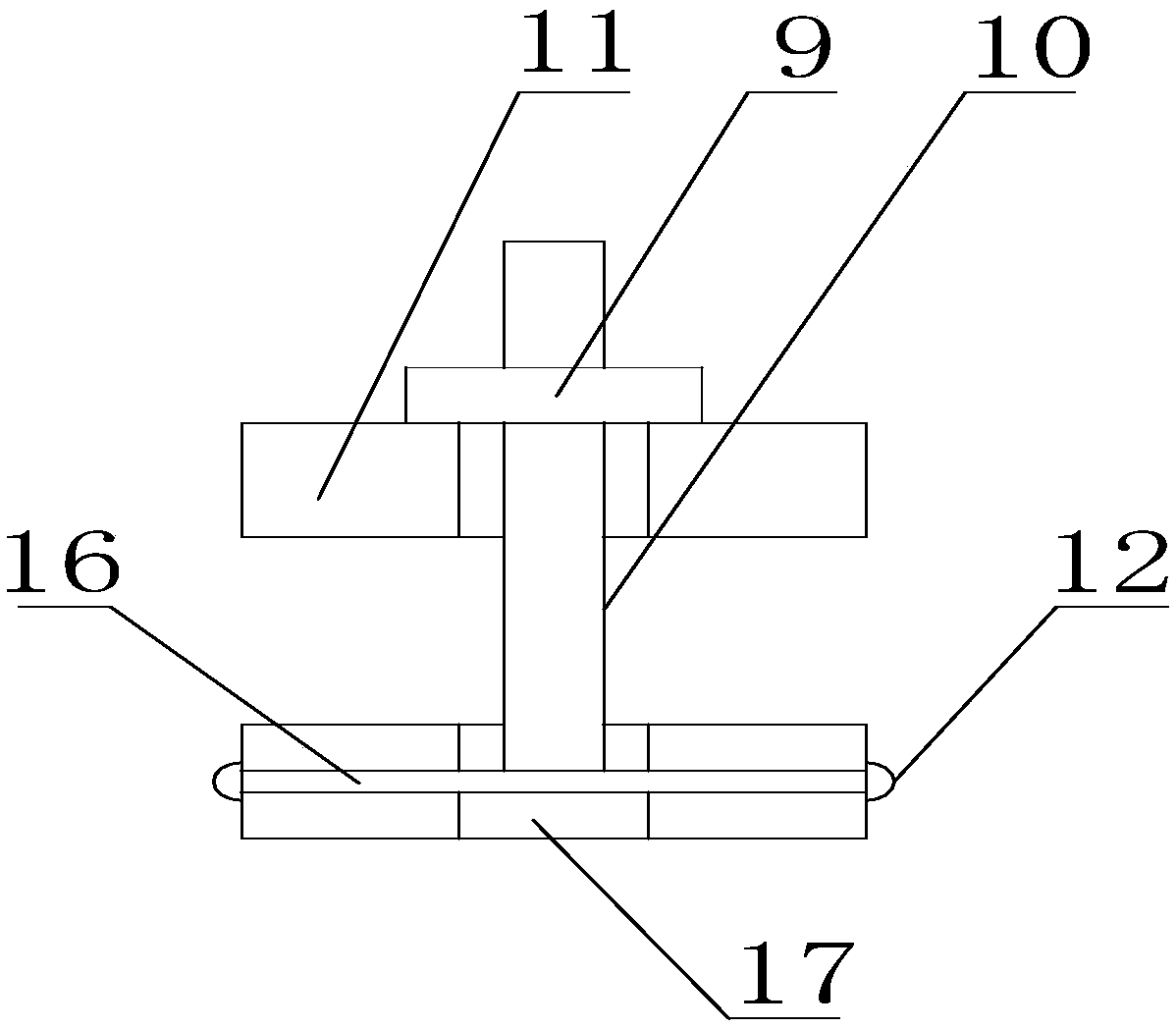

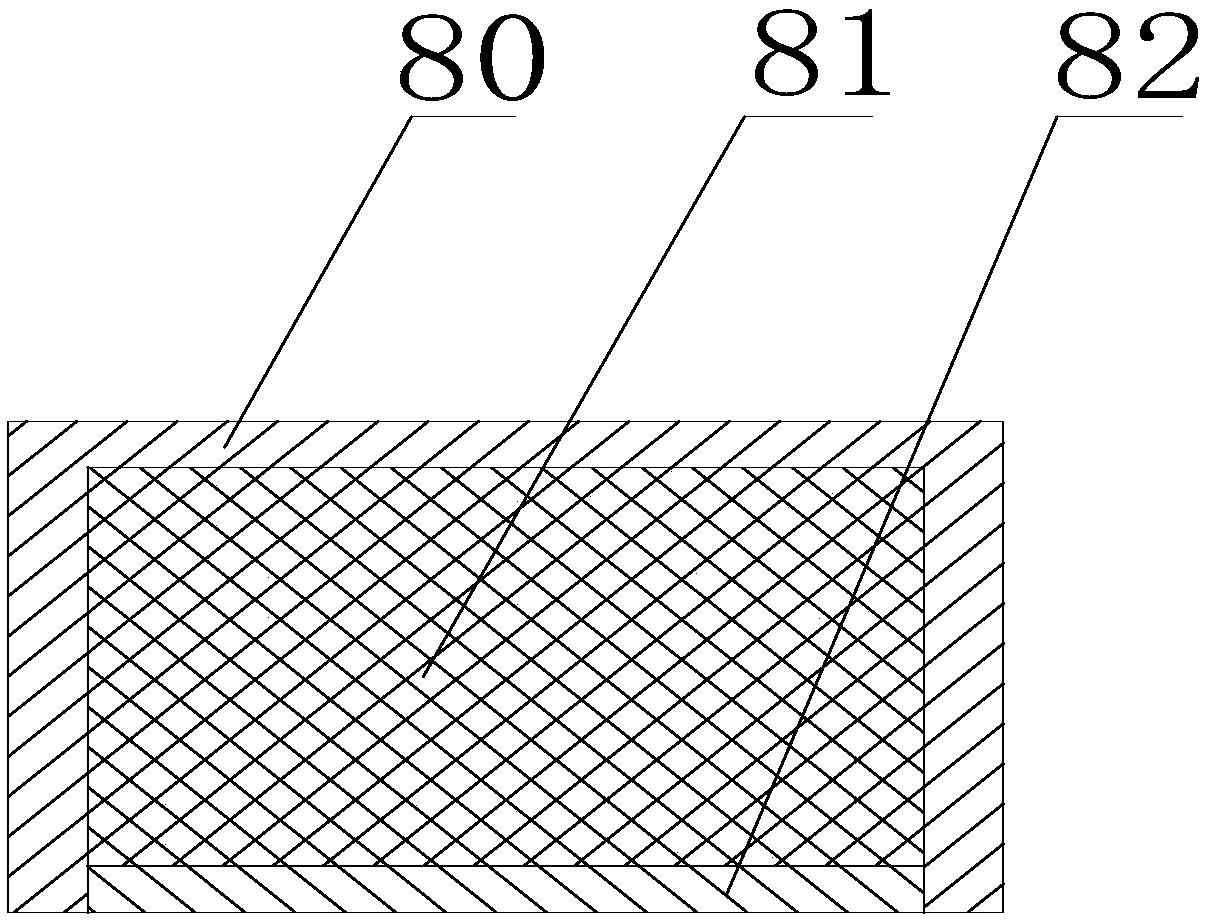

[0025] Such as Figure 1 to Figure 3 As shown, the heating type recovery device for the partial depression of steel of the present invention includes a support platform 1, a first connecting rod 3, a cross bar 4 and a second connecting rod 15, and the support table 1, the first connecting rod 3, and the cross bar 4 And the second connecting rod 15 is connected end to end in sequence to form a closed structure. A rotating element 2 is arranged between the supporting platform 1 and the first connecting rod 3. Both the supporting platform 1 and the first connecting rod 3 can surround the rotating element 2, and the supporting platform 1 and the first connecting rod 3 can both rotate around the rotating element 2. The support platform 1 is in the shape of an arc, and a gasket 13 is arranged inside the arc of the support platform 1. The gasket 13 is preferably made of rubber material and has a certain elasticity, and can protect the steel placed in the support platform 1, the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com